Pre-vacuumizing controlled atmosphere heat treatment furnace

A pre-evacuation and heat treatment furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large gas consumption, achieve the effect of reducing gas consumption, avoiding disturbance, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

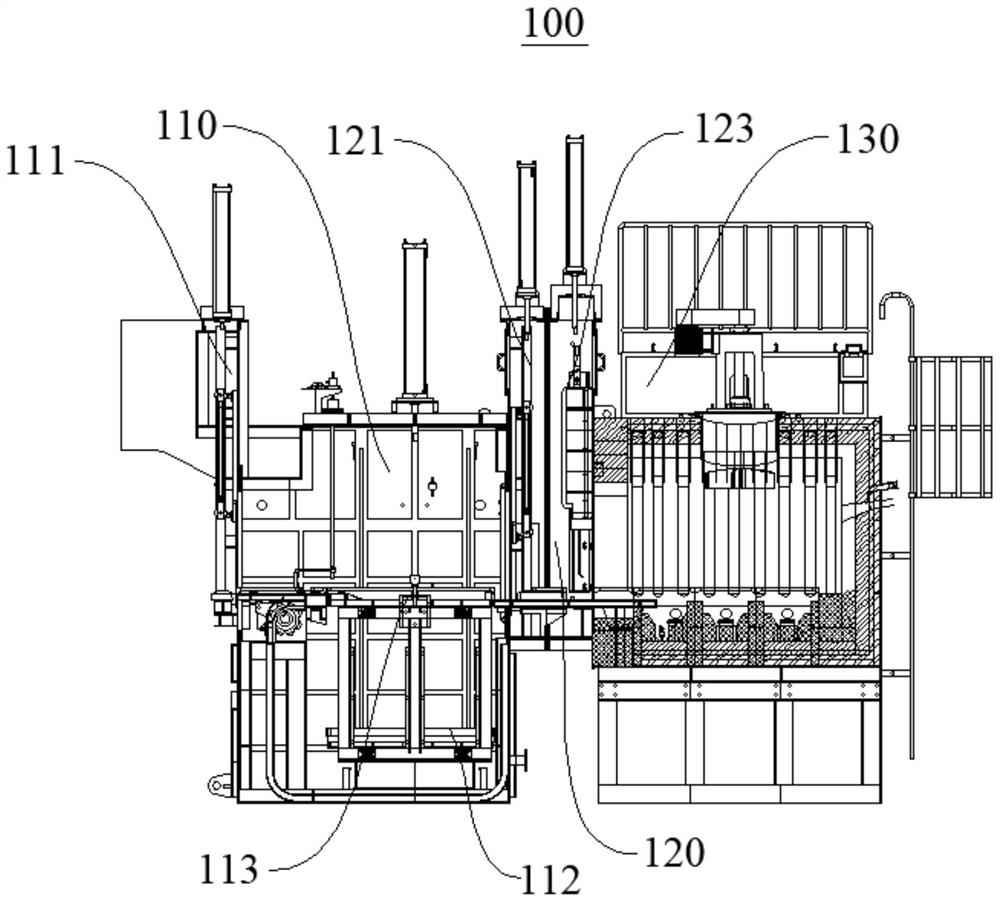

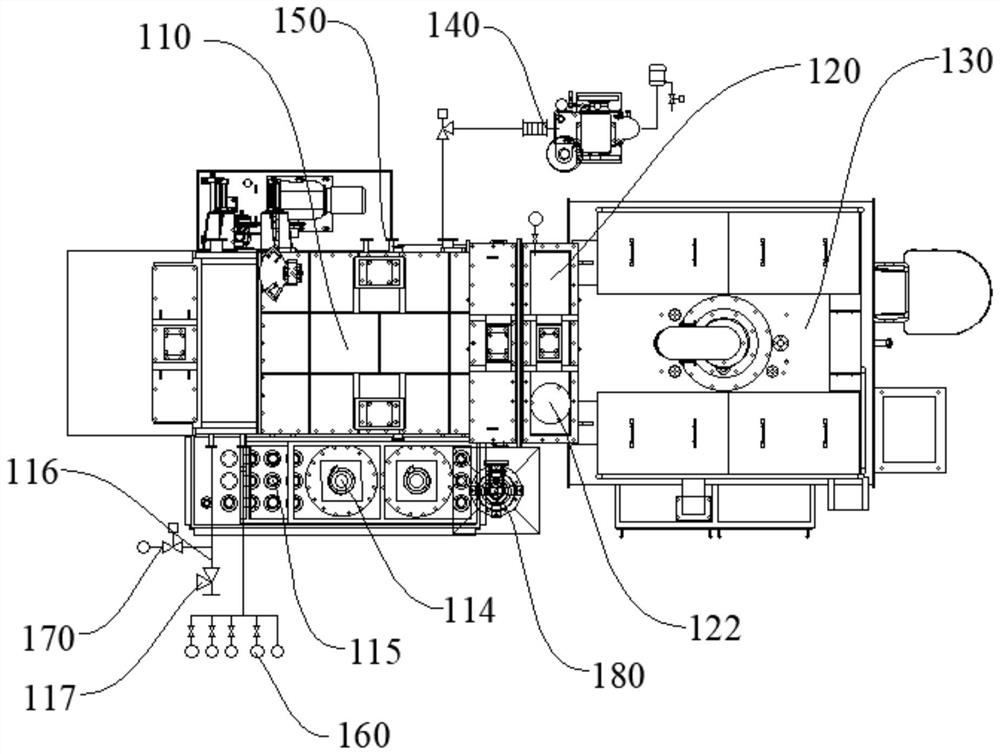

[0038] see figure 1 and figure 2 , this embodiment provides a pre-vacuum controllable atmosphere heat treatment furnace 100, which can reduce the gas consumption, and enable the workpiece to be heated, quenched or slowly cooled in an oxygen-less or oxygen-free environment, so that the quality of the processed workpiece can be improved. Good, and avoid the disturbance of the air to the heat treatment atmosphere, and reduce the intergranular oxidation of the workpiece during the heating and cooling process.

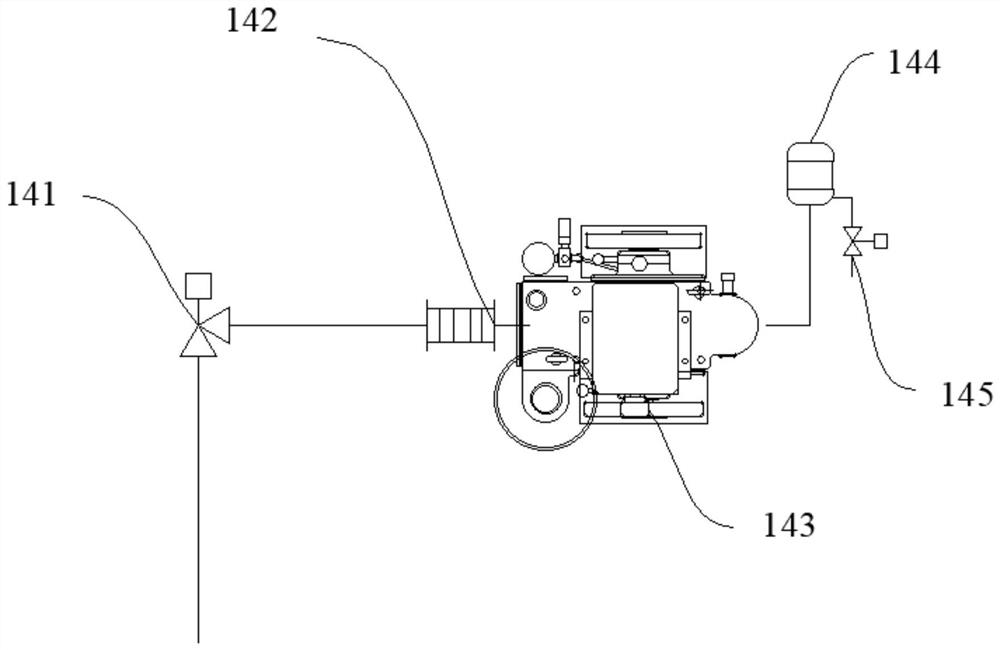

[0039] The pre-evacuation controlled atmosphere heat treatment furnace 100 provided in this embodiment includes a front chamber 110, a transition chamber 120, a heating chamber 130, a pre-evacuation device 140, a replacement gas introduction device 150, a pressure measurement device 160 and an oxygen probe 170, The heating chamber 130 is used to heat treat the workpiece, the front chamber 110 is used to cool the workpiece, the transition chamber 120 is connected to the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com