Cast-in-place box girder edge protection structure and construction method

A technology of edge protection and box girder, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor safety effect, and achieve the effect of easy construction, good safety, and improved impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

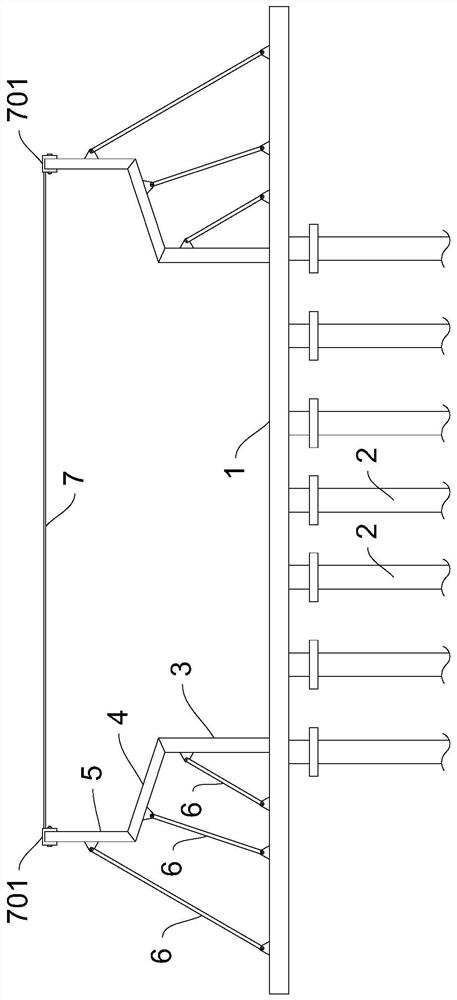

[0048] Please refer to Figure 1 to Figure 4 , shows a cast-in-situ box girder marginal protection structure provided by an embodiment of the present invention, and the structure is as follows.

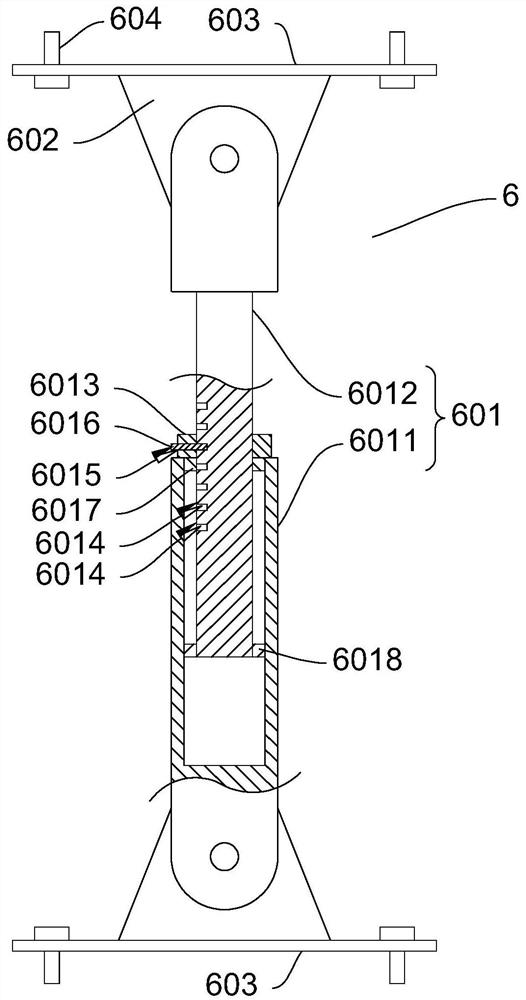

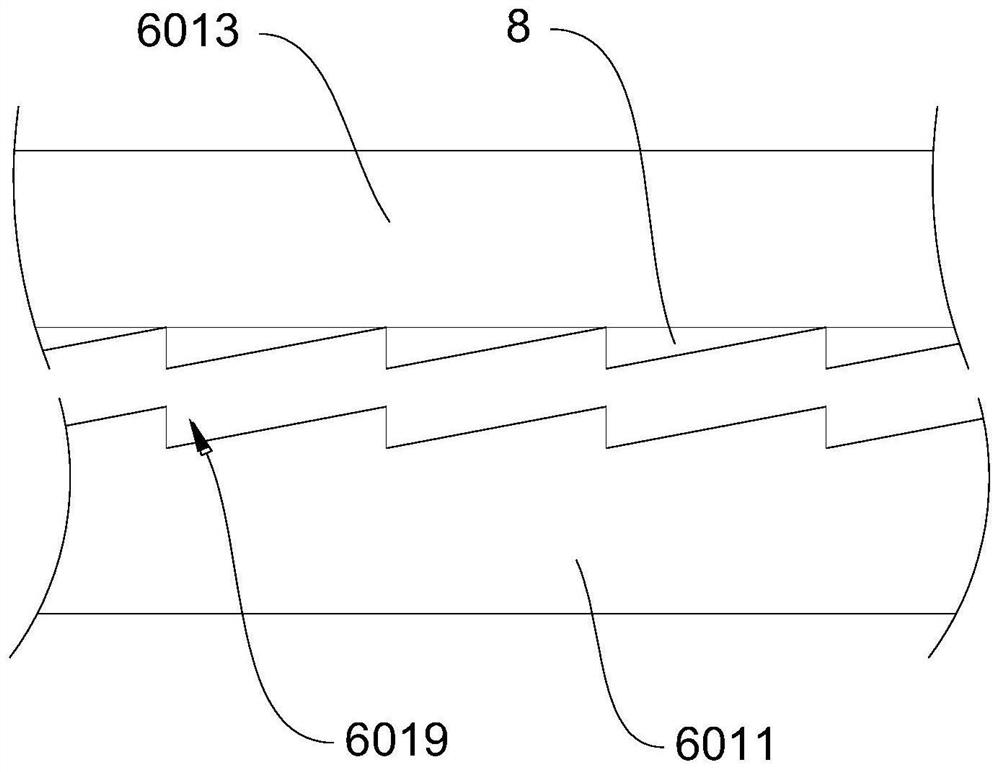

[0049] The embodiment of the present application provides a cast-in-place box girder border protection structure, which includes a main load-bearing beam 1. The top of the formwork 3 is provided with a cantilever support formwork 4, and the top of the cantilever support formwork 4 is provided with a border guardrail 5, and the main support formwork 3, the cantilever support formwork 4 and the border guardrail 5 are respectively connected with a support bar 6, and the bottom of the support bar 6 It is fixedly connected with the main load-bearing beam 1, and the tops of the guardrails 5 on both sides are provided with tension steel ropes 7. combine figure 1 As shown, there are multiple supports 2 for the whole hall, which jointly play a better supporting role for the main load-bearing...

Embodiment 2

[0061] In the second aspect, the embodiment of the present application provides a construction method, which includes the above-mentioned cast-in-place box girder edge protection structure, and further includes the following steps,

[0062] S1. Vertically install the full-wall support 2, the bottom of the full-wall support 2 is inserted into the ground, the adjacent full-wall support 2 is fixedly connected by steel pipes and fasteners, and the main load-bearing beam 1 is installed on the top of the full-wall support 2,

[0063] S2. Fix and install the main support formwork 3, the cantilever support formwork 4 and the border guardrail 5 in sequence, and the border guardrail 5 and the cantilever support formwork 4 are fixed by nailing,

[0064] S3, the bottom of the support bar 6 and the main load-bearing beam 1 are fixed by bolts, and the top of the support bar 6 is fixed to the main support formwork 3, the cantilever support formwork 4 or the edge guardrail 5,

[0065] S4. Ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com