Concrete structure of in-situ protective large-diameter oil-gas pipeline and construction method

A technology for concrete structures and oil and gas pipelines, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc. It can solve problems such as restricting the progress of highway and railway construction, high resource consumption, and impact on construction period. The effect of alleviating the shortage of energy supply, facilitating later maintenance, and speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

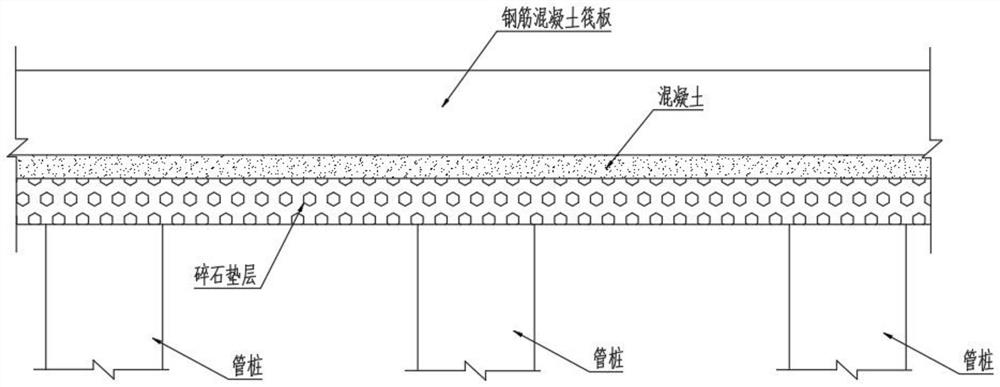

[0057] A concrete structure and construction method for in-situ protection of large-diameter oil and gas pipelines. Before construction, construction preparation and construction platform filling are required;

[0058] Construction preparation includes (1) holding a pre-construction safety meeting, clarifying the on-site command and each group of personnel, conducting construction disclosure and emphasizing the precautions and preventive measures for operation safety; (2) getting familiar with the drawings, understanding the design requirements and the technical standards that should be met during construction, Clarify the construction process; disclose the approved construction and safety plans to the construction team leader, squad leader, and construction personnel (including steel workers, carpenters, surveyors, and concrete workers), and guide the on-site construction; (3) organize materials and equipment for inspection; field.

[0059] The construction platform filling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com