Auxiliary device for bridge load test detection

A technology of load test and auxiliary device, applied in measuring device, using repetitive force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of lack of detection and collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

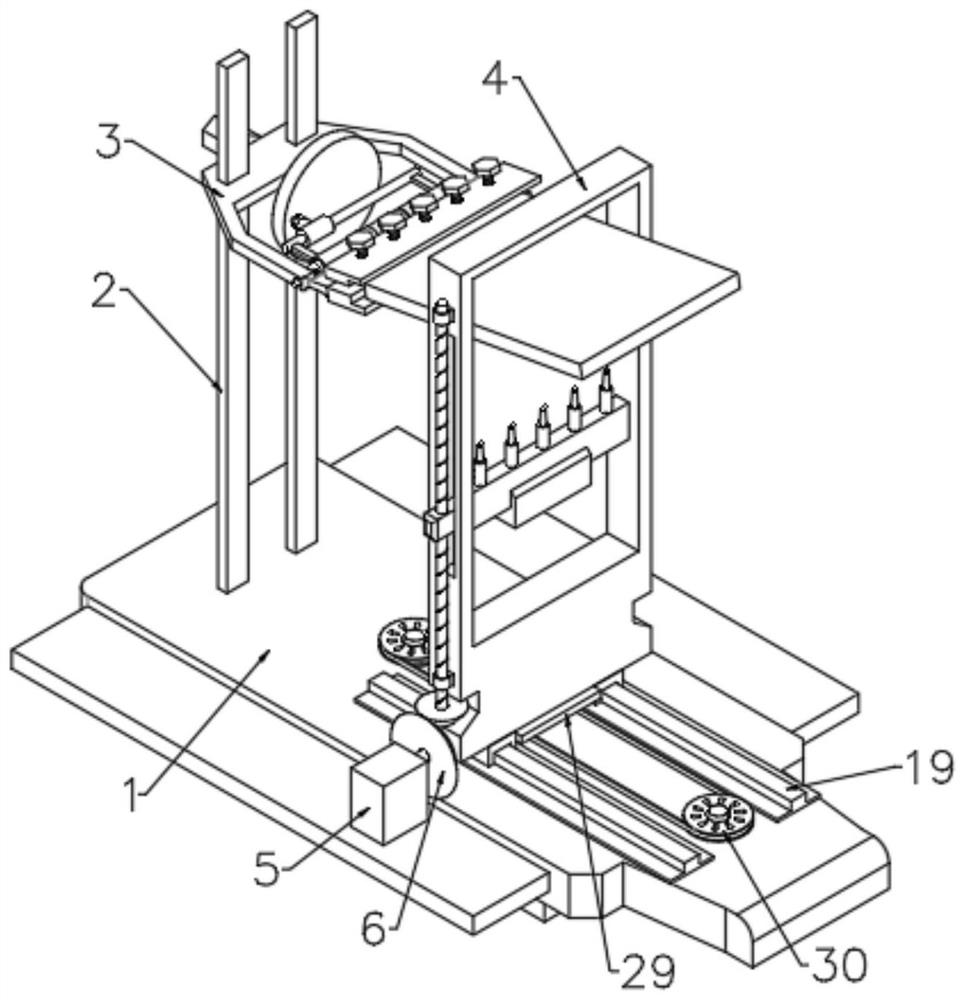

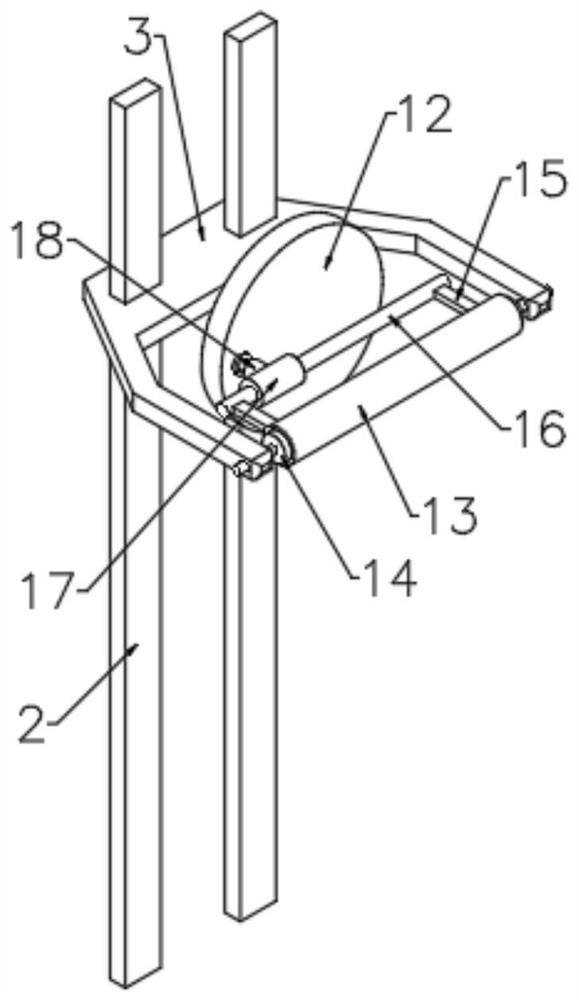

[0035] refer to Figure 1-7 , in an embodiment of the present invention, an auxiliary device for bridge load test detection includes a base 1, and a U-shaped mounting frame 3 and a fixing frame 4 are sequentially arranged above the base 1, and the U-shaped mounting frame 3 is installed on the base through intervals. The two support columns 2 on the seat 1 are fixed and suspended, and the U-shaped mounting frame 3 is connected with a connecting block 9 through a tilting mechanism. The bottom of the frame 4 is symmetrically equipped with two sliding blocks 28, and the top surface of the base 1 is provided with two guide rails 19 for the sliding installation of the two sliding blocks 28 respectively. Matching reciprocating mechanism; the fixed frame 4 is provided with a lifting base 20, the top surface of the lifting base 20 is provided with a plurality of data detection probes 22 at intervals, and the bottom side of the lifting base 20 is installed with a plurality of data detec...

Embodiment 2

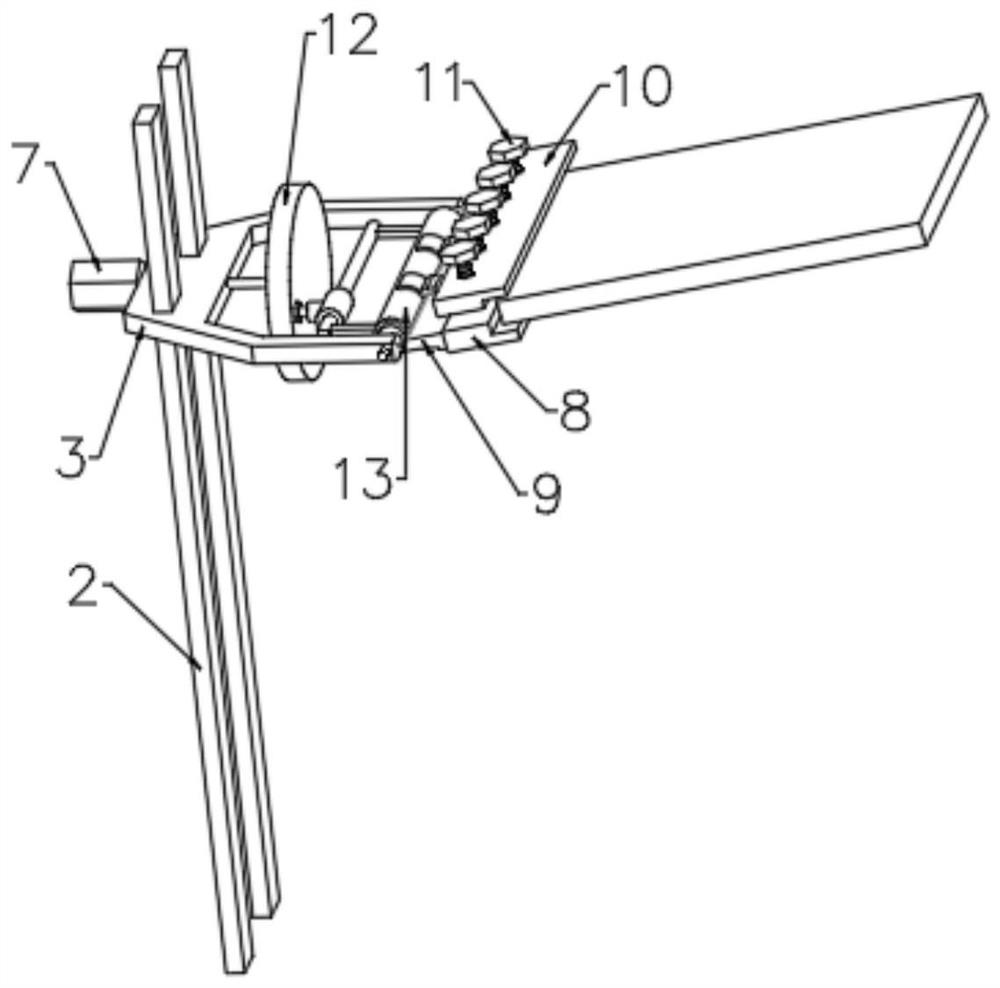

[0041] The difference between this embodiment and Embodiment 1 is that the clamping mechanism includes a fixed clip seat 8 fixed on the end surface of the connecting block 9 facing away from the roller 13, and a movable clip seat 10 is movably arranged on the fixed clip seat 8, and the movable clip seat 10 is A plurality of locking bolts 11 are arranged at intervals, and the tightening of the locking bolts 11 realizes the clamping of the cut reinforced concrete block through the movable clamp seat 10 and the fixed clamp seat 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com