Cloth surface defect detection device and method based on machine vision

A defect detection and machine vision technology, used in measuring devices, instruments, scientific instruments, etc., can solve problems such as damage to the eyesight of cloth inspectors and boring cloth defect detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

[0049] The object of the present invention is to provide a cloth surface defect detection device and method based on machine vision, so as to quickly identify the defect area in the textile cloth defect image and realize the automation of cloth quality detection.

[0050] To achieve the above object, the present invention adopts the following technical solutions:

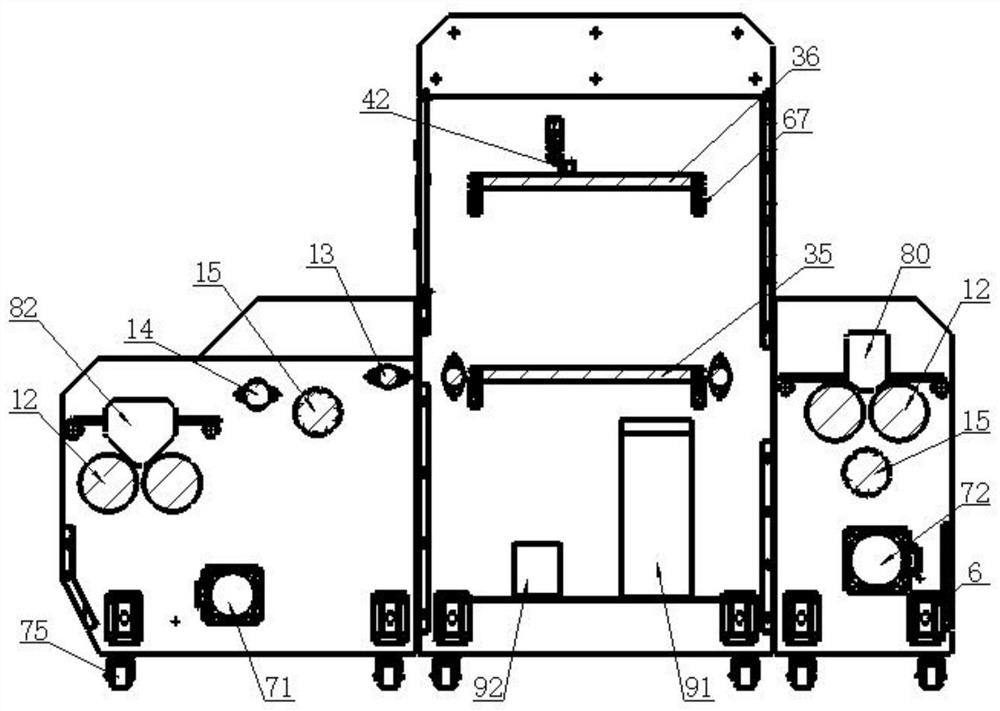

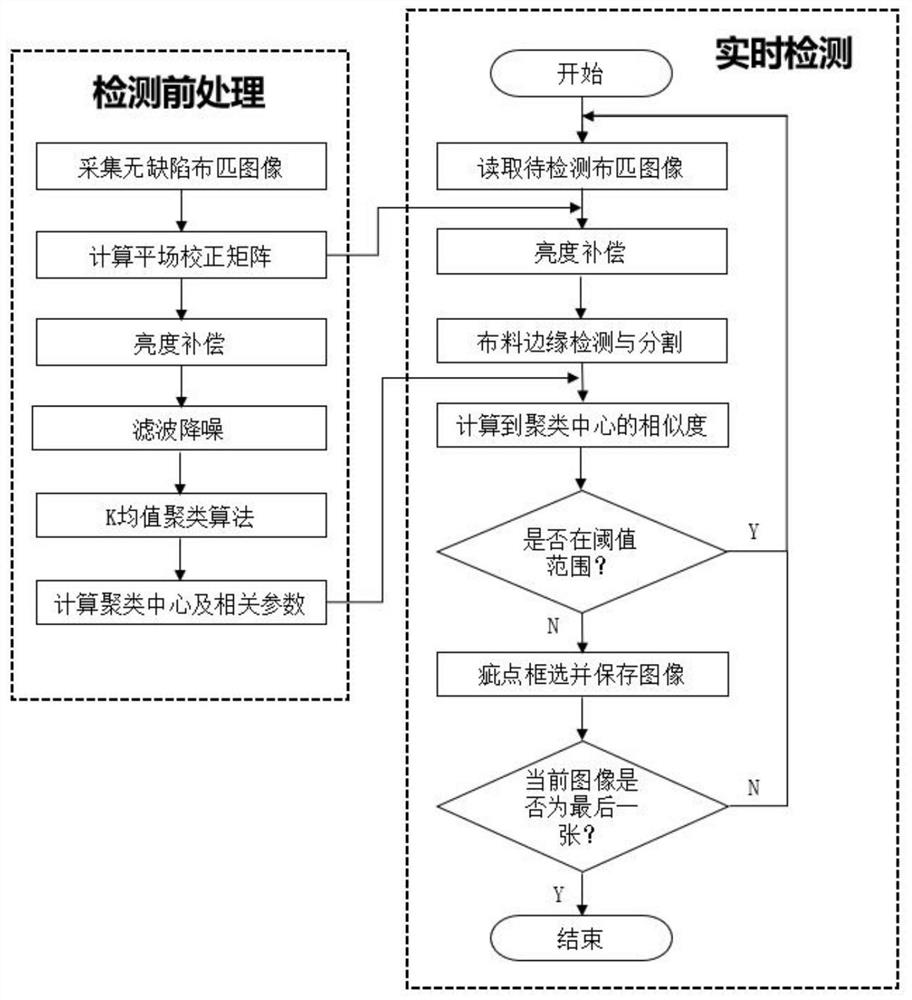

[0051] A cloth surface defect detection device based on machine vision, the detailed structure can be seen figure 1 , including mechanical components assembled in modules, including a preprocessing module, a visual inspection module, and a winding module. The preprocessing module flattens the cloth in progress and sends it to the visual inspection module. The image of the cloth is used for defect detection, and the winding module performs side-to-side winding of the detected cloth.

[0052] The aforementio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com