Quality detection intelligent control method and device, terminal equipment and storage medium

A technology of intelligent control and quality, applied in data processing applications, instruments, computing, etc., can solve the problems of inability to trace data, slow notification information delivery process, and too much data, so as to improve product testing efficiency and product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

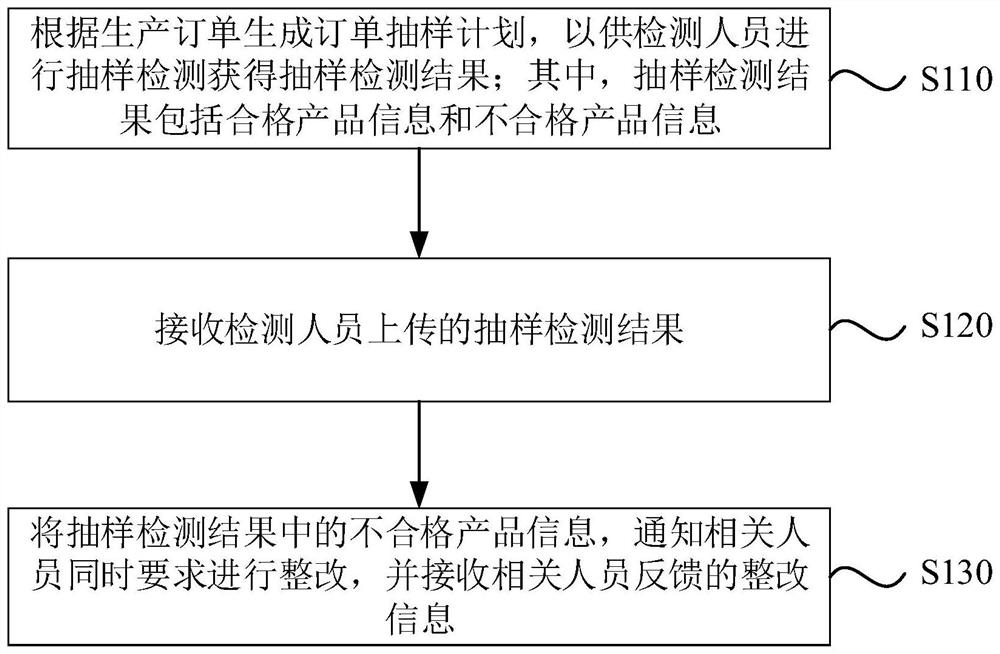

[0033] figure 1 It is a schematic flow chart of a quality inspection intelligent control method provided in Embodiment 1 of the present invention. This method is applicable to the situation of refrigerator quality inspection. The method can be executed by a quality inspection intelligent control device, wherein the device can be controlled by software and / or Or hardware implementation, and generally integrated on the terminal equipment, in this embodiment, the terminal equipment includes but not limited to: computers and other equipment.

[0034] like figure 1 As shown, a quality detection intelligent control method provided by Embodiment 1 of the present invention includes the following steps:

[0035] S110. Generate an order sampling plan according to the production order, so that inspectors can perform sampling inspection to obtain sampling inspection results; wherein, the sampling inspection results include qualified product information and unqualified product information...

Embodiment 2

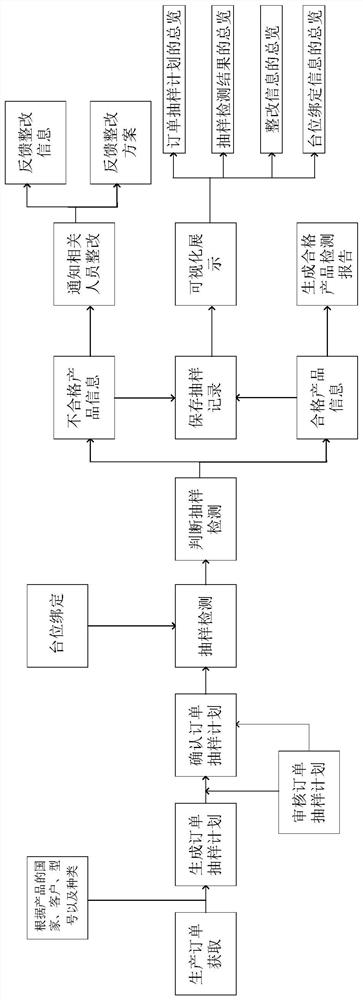

[0064] Figure 4 It is a schematic flowchart of a quality detection intelligent control method provided by Embodiment 2 of the present invention. This Embodiment 2 is optimized on the basis of the foregoing embodiments. Figure 5 It is a schematic flow diagram of a quality detection intelligent control method provided by Embodiment 2 of the present invention. In this embodiment, the quality inspection intelligent control method and system in Embodiment 1 are further embodied as:

[0065] S210. Generate an order sampling plan according to the production order, so that inspectors can perform sampling inspection to obtain sampling inspection results; wherein, the sampling inspection results include qualified product information and unqualified product information.

[0066] Further, after the above step S210, it also includes:

[0067] S211 , issuing an audit instruction or notice on the order sampling plan, so that the testing personnel can confirm the order sampling plan.

[...

Embodiment 3

[0088] Image 6 It is a structural diagram of an intelligent control device for quality inspection provided by Embodiment 3 of the present invention. This device is applicable to the situation of quality inspection of refrigerators. The device can be implemented by software and / or hardware, and is generally integrated on terminal equipment.

[0089] like Image 6 As shown, the quality inspection intelligent control device includes:

[0090] The order sampling plan generating module 61 is used to generate an order sampling plan according to the production order, so that inspectors can perform sampling inspection to obtain sampling inspection results, wherein the sampling inspection results include qualified product information and unqualified product information.

[0091] The sample test result receiving module 62 is configured to receive the sample test result uploaded by the test personnel.

[0092] The notification rectification module 63 is used for notifying relevant per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com