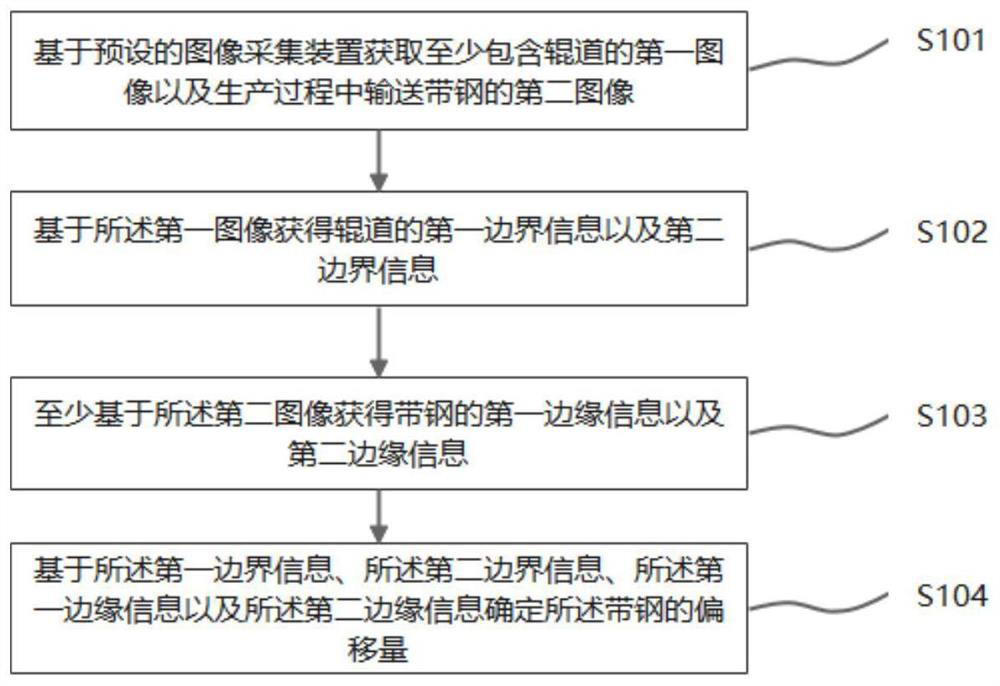

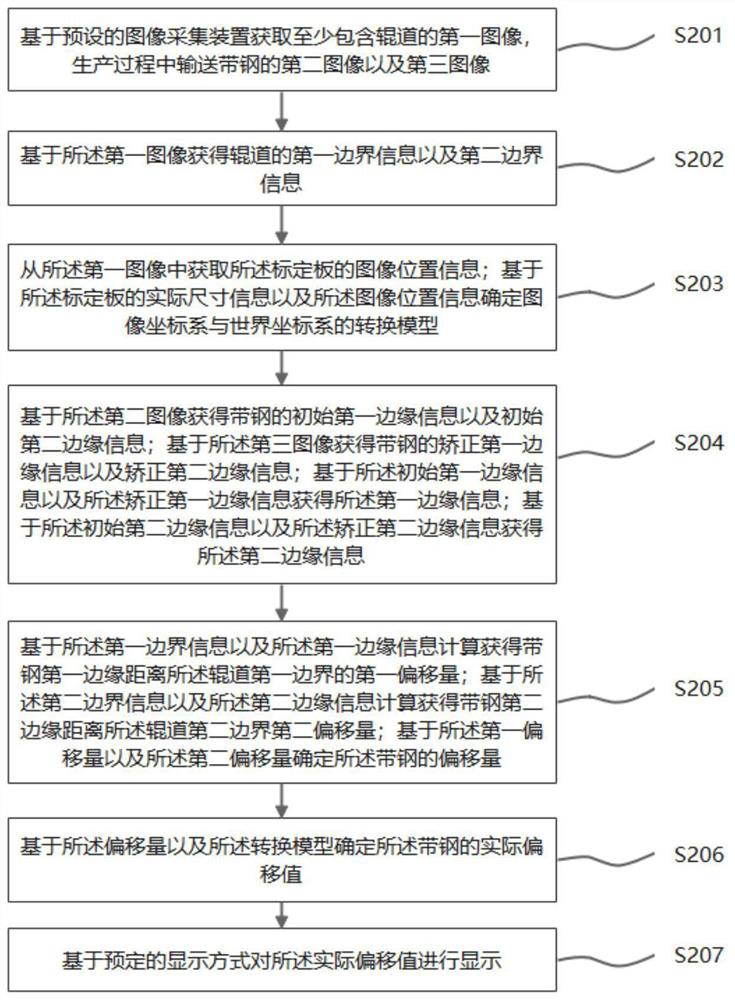

Strip steel offset detection method and system

A detection method and offset technology, applied in the field of metallurgy, to meet actual production needs, strong detection and anti-interference ability, and accurate offset detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The various programs and features of the present application are described herein.

[0043] It should be understood that various modifications can be made in the embodiments of the application. Therefore, the above description should not be considered as limiting, but is merely examples of embodiments. Those skilled in the art will think of other modifications within the scope of the present application.

[0044] BRIEF DESCRIPTION OF THE INVENTION The embodiments of the present application are included in the specification and constitute a general description of the present application and the detailed description of the embodiments given in the present application and the detailed description given below. principle.

[0045] These and other features of the present application will become apparent from the description of the preferred form of the embodiments of the embodiments of the present invention.

[0046] It should also be understood that although the present applicat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap