Cyclone backflow type waste gas purifier system

A technology of exhaust gas purifier and cyclone separator, which is applied in the fields of climate change adaptation, chemical instruments and methods, climate sustainability, etc., can solve the problem that the effect of gas degreasing and purification cannot be achieved, the requirements of dust separation cannot be met at the same time, and the dust removal and purification cannot be affected. Efficiency and other issues, to achieve the effect of simple structure, good dust removal effect, versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

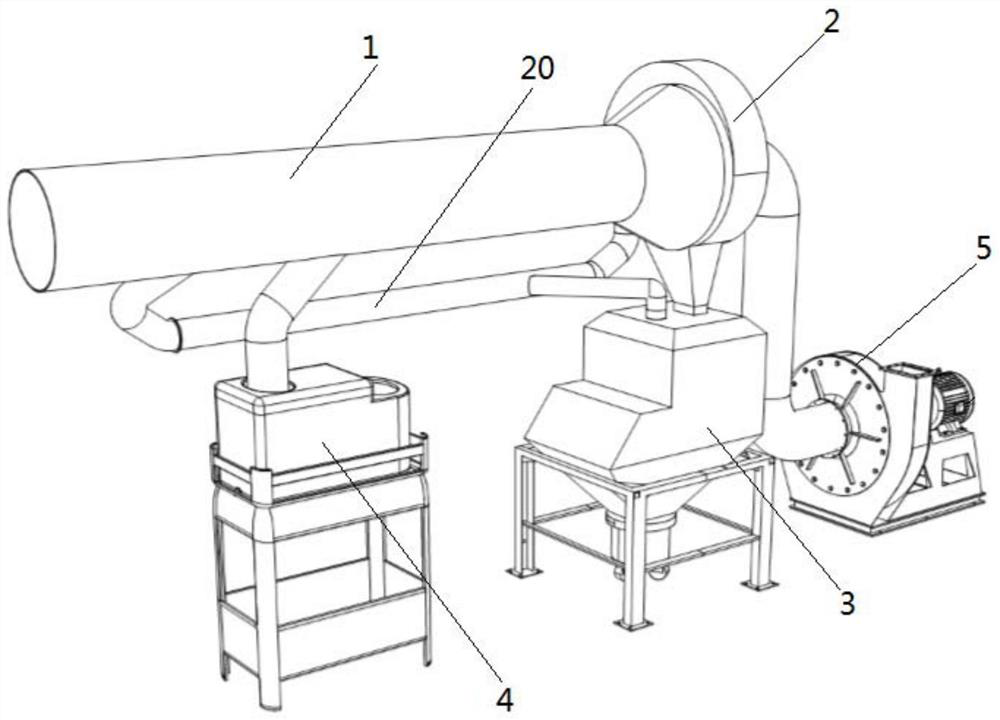

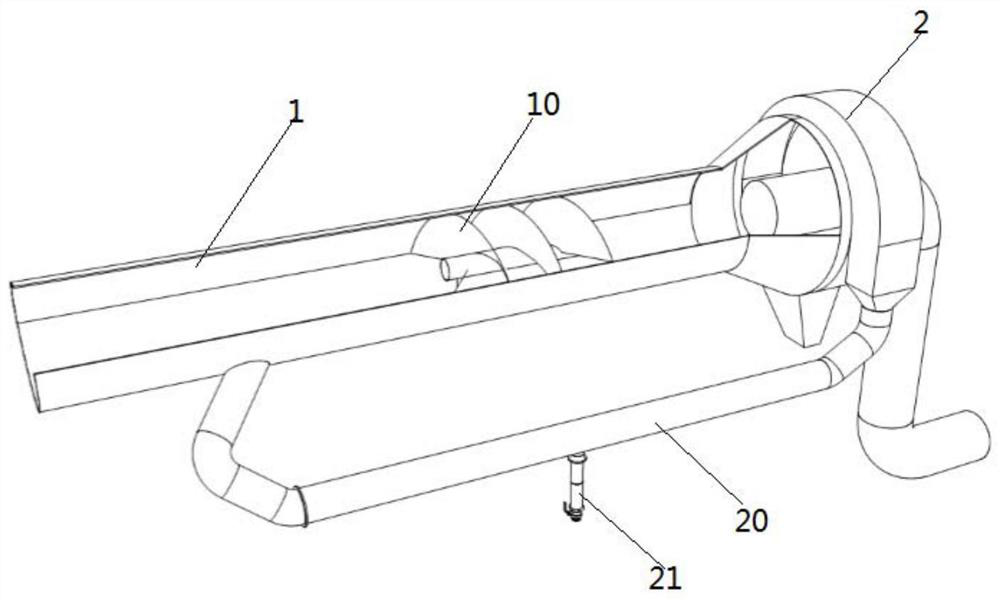

[0030] The present invention discloses a cyclone backflow exhaust gas purifier system, such as figure 1 As shown, it includes a cyclone pipeline 1, a cyclone separator 2, an inertial separation exhaust gas purifier 3, an emulsifier atomizing device 4 and a fan 5;

[0031] The cyclone pipeline 1 and the cyclone separator 2 are arranged horizontally and coaxially, which can overcome the problem that the dust in the existing cyclone dust collector is brought up by the vortex rotation, and then solve the problem of low dust removal efficiency; the cyclone pipeline 1 is connected to the cyclone separator The dusty gas inlet of device 2;

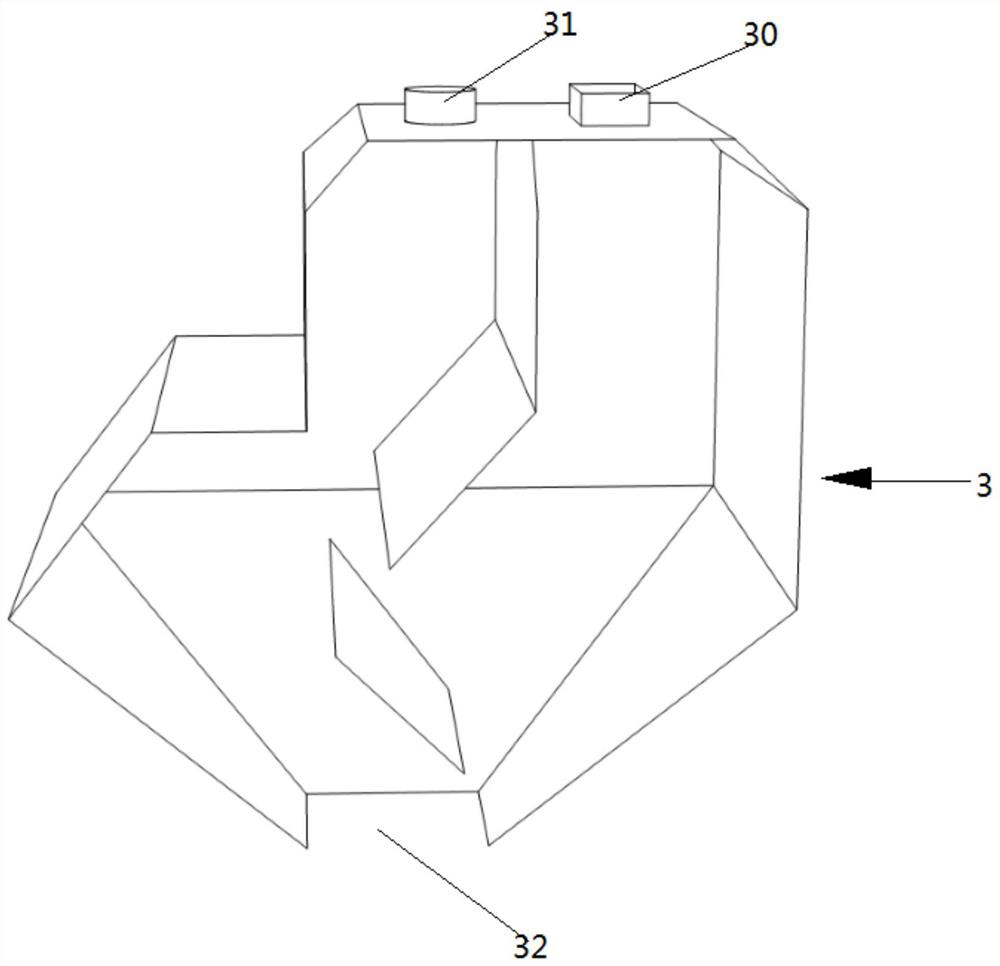

[0032] The inertial separation exhaust gas purifier 3 is connected to the dusty gas outlet of the cyclone separator 2;

[0033] The fan 5 is connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com