A kind of composite material grid product and preparation method thereof

A composite material and grid technology, applied in the coating and other directions, can solve the problems of poor uniformity and poor heat resistance, and achieve the effect of uniform strength, continuity, and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

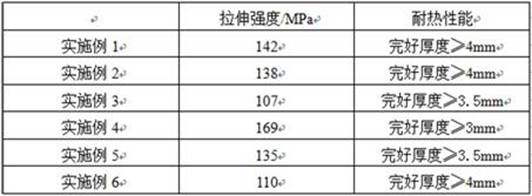

Embodiment 1

[0034] The method for preparing a composite grid product described in this embodiment includes the following steps:

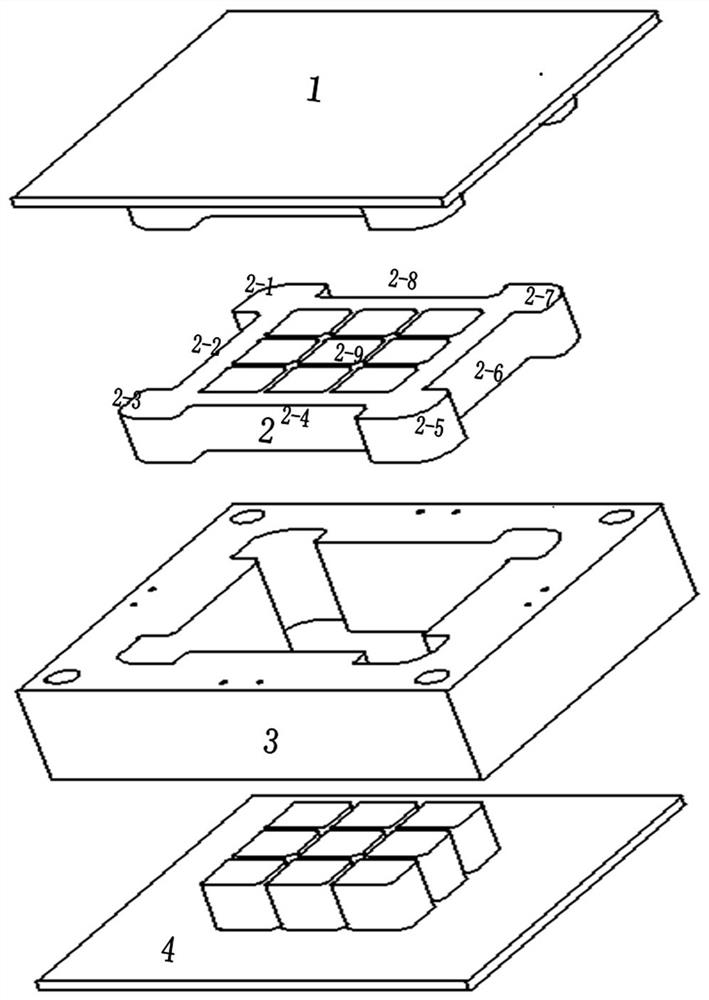

[0035] S0a. According to the load-bearing requirements of the product, the paving design is carried out according to the stress situation. In this embodiment, the product is as follows figure 1 The grid shown has a support structure at the edges for the paving design;

[0036] S0b. Design the mold according to the structure of the product. When designing the mold, consider the size and material of the mold, the structure of the product, the shear edge during pressing, the guide column, the temperature field, the mold release method, etc.; the mold material should be guaranteed to be able to It can withstand high temperature and high pressure for a long time without deformation, and has good wear resistance and high surface finish; the length of the shearing edge is generally about 1mm, and it is easy to tear if it is too long; The sleeve has a certain clearanc...

Embodiment 2

[0044] In the method for preparing a composite grid product described in this embodiment, the remaining steps are the same as those in Embodiment 1, the difference is that in step S5, the mold is forcibly cooled to below 60° C. and demolded.

Embodiment 3

[0046] In the method for preparing composite grid products described in this example, the remaining steps are the same as those in Example 1, the difference is that in step S4, the temperature rise rate is not controlled, and the temperature is directly raised to 160°C, and the holding time remains unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com