Reinforcement repair method for blade trailing edges of wind turbine

A technology for wind turbine blades and repair methods, which is applied to other household appliances, household appliances, household components, etc., and can solve the problems of the trailing edge bonding area not reaching the service life, blade replacement, and operation damage, so as to avoid blade breakage accidents , reduce operation and maintenance costs, and reduce operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments.

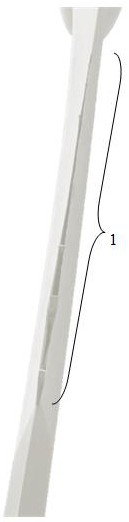

[0028] refer to figure 1 , The trailing edge is a very important load-bearing structural part of a wind turbine blade. Aiming at the cracking damage 1 of the trailing edge of the blade, the present invention provides a reinforcing method for repairing the cracking damage of the trailing edge.

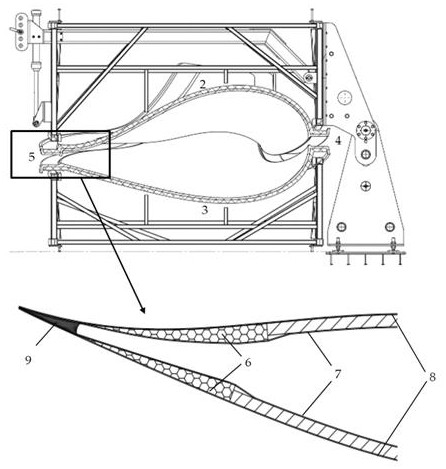

[0029] refer to figure 2 , the two shells of the windward side 2 and the leeward side 3 of the wind turbine blade are molded and bonded, and the forming method is that the leading edge, trailing edge of the blade and the connection area between the web and the shell are all bonded and solidified with structural adhesives method, the leading edge splitting point 4 and the trailing edge splitting point 5 of the blade section are formed. The main structural layers affecting the bonding quality at the trailing edge of the wind turbine blade are the trailing edge beam 6, the inner skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com