Intelligent high-precision screen printing machine

A screen printing machine, high-precision technology, used in screen printing machines, printing machines, screen printing and other directions, can solve the problems of light printing color of adhesive products, affecting the quality of adhesive products, and ink dispersion to both sides, etc., to achieve color Vivid, prevent ink loss, reduce the effect of adding ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

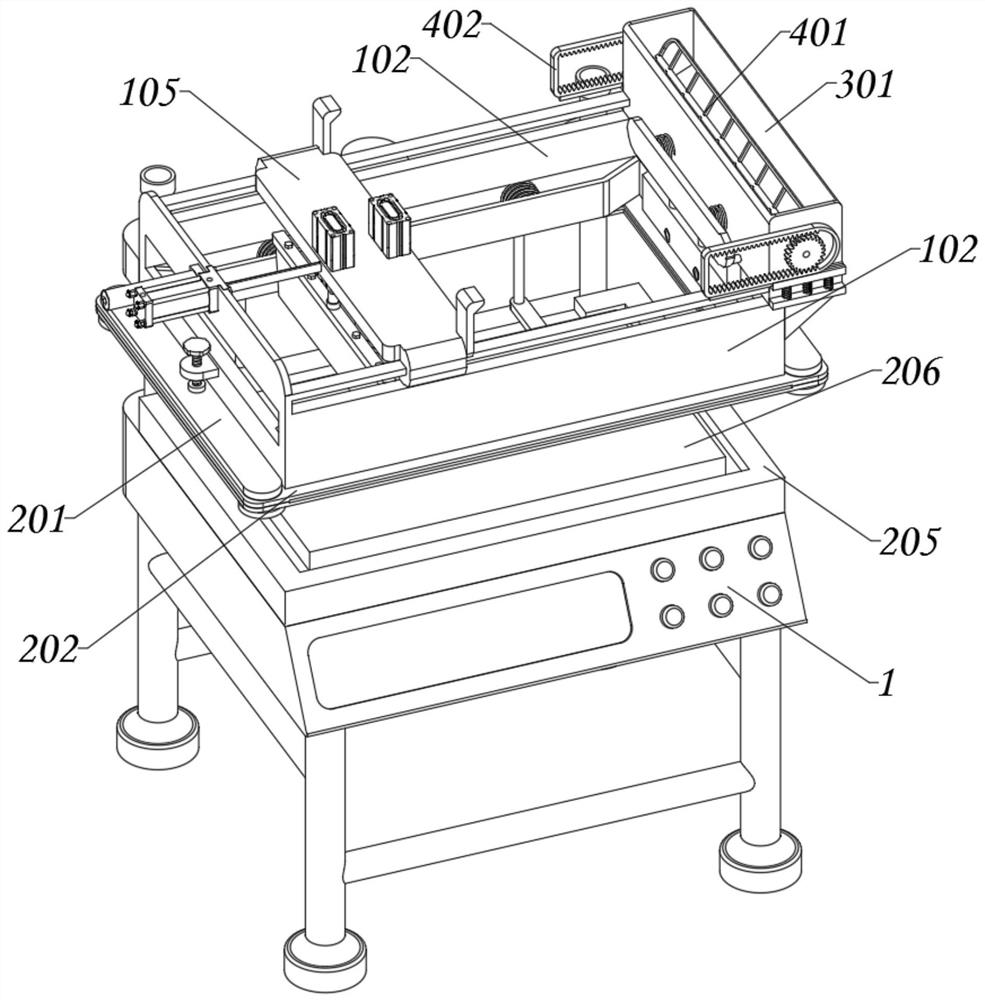

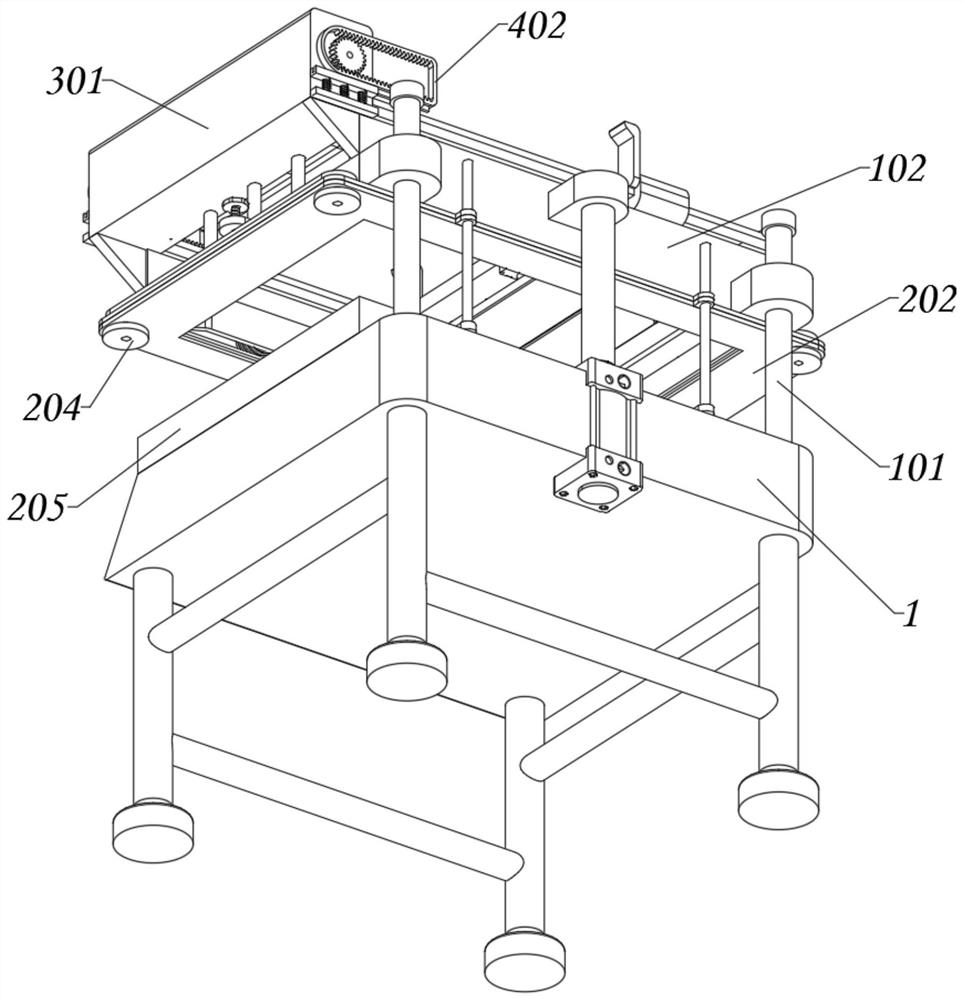

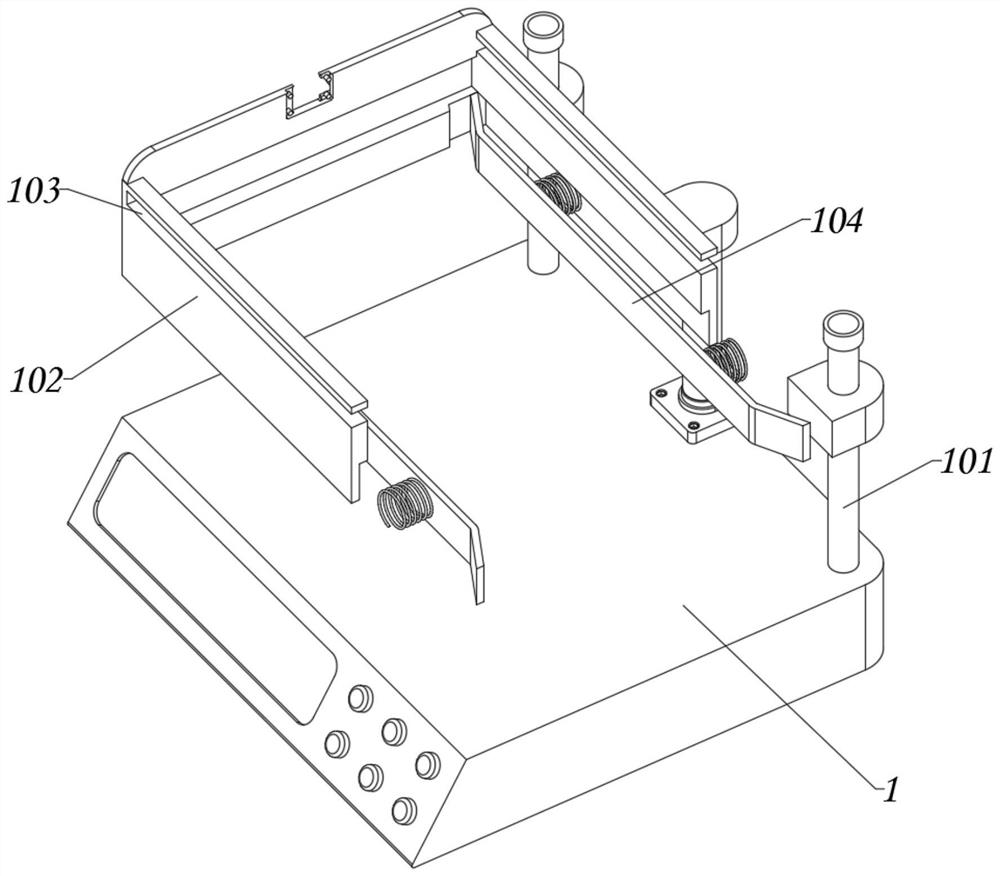

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides an intelligent high-precision screen printing machine, including:

[0036] refer to figure 1 , figure 2 and image 3As shown, the main body 1, the bottom of the main body 1 is equipped with outriggers, and the bottom of the main body 1 is equipped with outriggers to support the height of the main body 1, and the side of the main body 1 is equipped with a cylinder, and the front side of the main body 1 is equipped with an operating The display screen and the operation button, and the top of the main body 1 is equipped with a positioning mechanism 2, the main body 1 includes: a vertical bar 101, the vertical bar 101 is a cylindrical structure, and the vertical bar 101 is installed on the top side of the main body 1; The inner side of the plate 102 is provided with a groove, and the top side of the supporting plate 102 is equipped with a cylinder, and the side of the supporting plate 102 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap