A warm air radiator

A radiator and warm air technology, applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc., can solve the problems of lack of rapid heating, occupying vehicle space, small heat dissipation area, etc., to reduce size and increase heat dissipation Time, the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

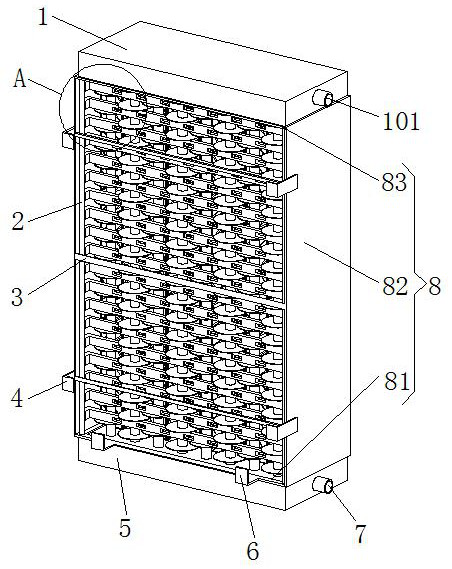

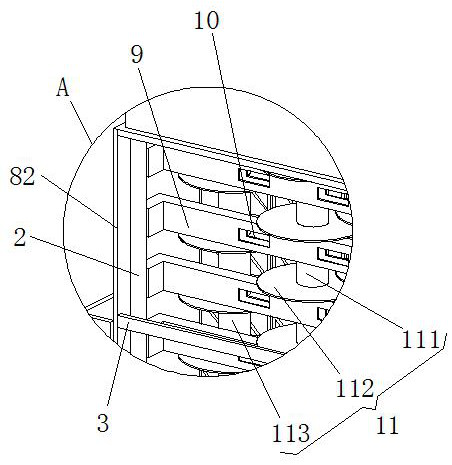

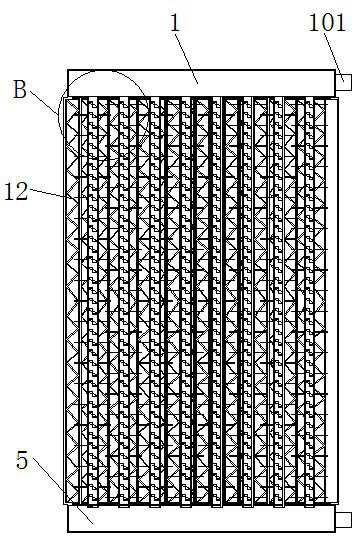

[0033] see Figure 1-12 , the present invention provides a technical solution: a warm air radiator, including an upper water chamber 1, a lower water chamber 5, a frame assembly 8, a gas preheating pipe 9, a standpipe heat dissipation assembly 11, a special-shaped heat dissipation assembly 14, and a purification box 15 , the frame assembly 8 includes a lower fixed frame 81 and an upper fixed frame 83, a support rod 2 is arranged between the lower fixed frame 81 and the upper fixed frame 83, the upper water chamber 1 is fixed on the upper fixed frame 83, and the lower water chamber 5 is fixed on the lower fixed frame 83. On the frame 81, the standpipe heat dissipation assembly 11 is arranged between the upper water chamber 1 and the lower water chamber 5. The standpipe heat dissipation assembly 11 includes a standpipe I111 and a standpipe II113. The heat dissipation disc 112, the interior of the standpipe I111 and the interior of the standpipe II113 are provided with spiral fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com