Hollow slab beam shear-resistant reinforcing method and hollow slab beam shear-resistant reinforcing device

A hollow slab beam and reinforcement device technology, applied in bridge reinforcement, bridge, bridge maintenance and other directions, can solve problems such as structural damage, and achieve the effects of avoiding cracking, avoiding beam-slab vibration, and weakening the stress state of a single beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

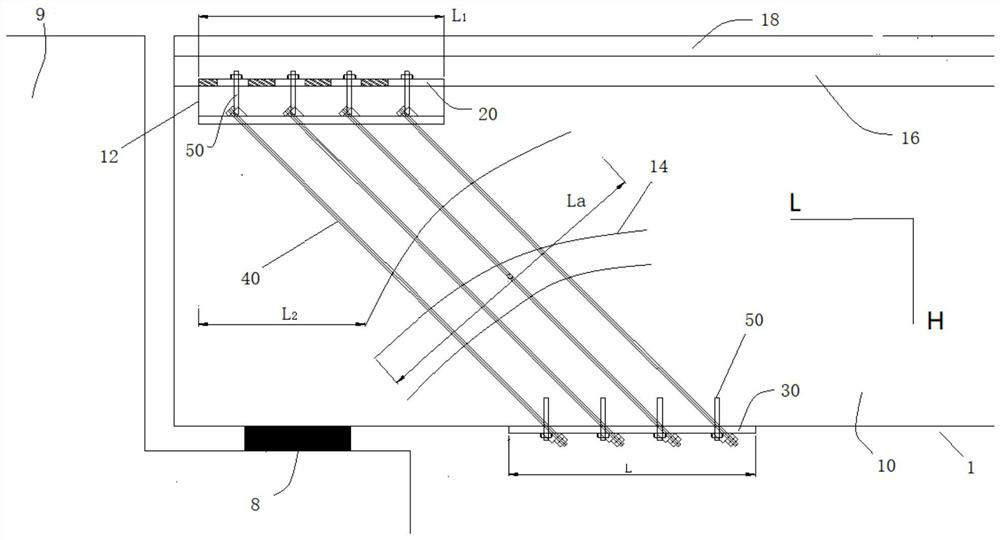

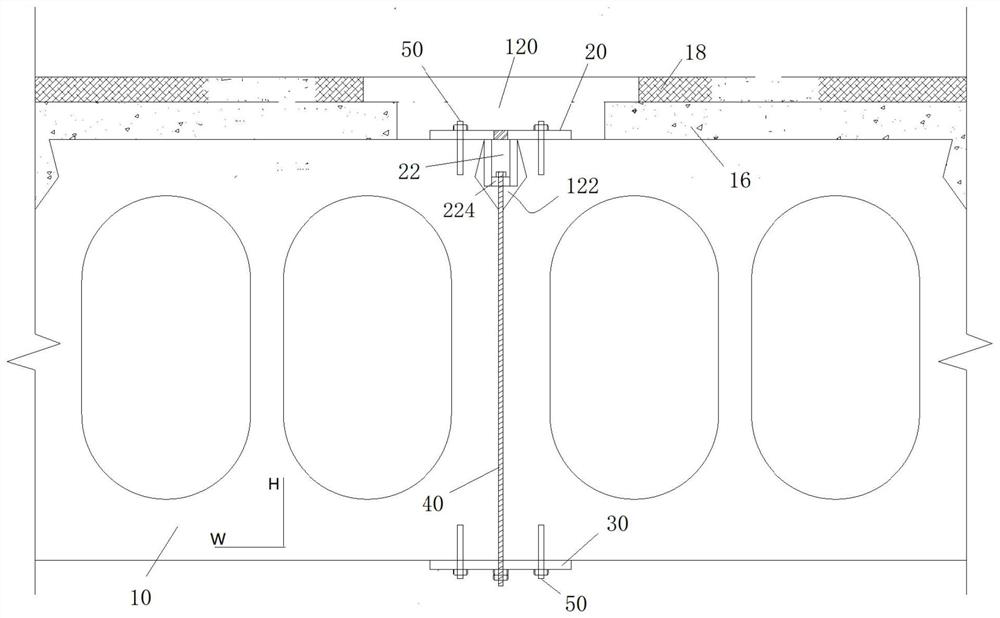

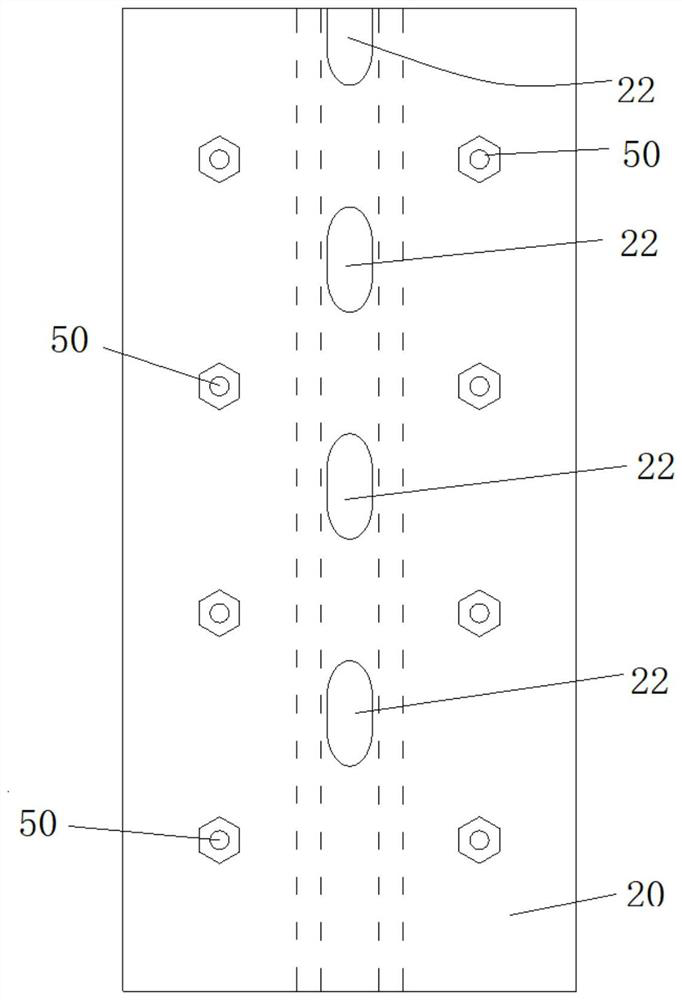

[0048] According to one aspect of the present invention, a shear strengthening method of a hollow plate girder is provided. see figure 1 with figure 2 , the hollow slab beam reinforcement method includes the following steps:

[0049] Firstly, a recessed area 12 is provided on the upper end of the bridge 1 .

[0050] The bridge 1 comprises a hollow slab girder 10 . A hinge joint is formed in the hollow plate girder 10 of the bridge 1 . At least one through hole is provided in the hinge joint of the hollow plate girder 10 , which communicates with the recessed region 12 . In this embodiment, hinged joint refers to the post-cast concrete (filling joint) between the prefabricated slab girders in the bridge 1 project, which connects two slab girders, and is carried out before the bridge deck pavement construction after the slab girders are installed. For example, as shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com