Textile inspection device

An inspection device and textile technology, applied in the field of textile processing, can solve the problems of deviation of detection results, time-consuming and labor-intensive, affecting the normal use of ultraviolet sensors, etc., and achieve the effect of convenient disassembly and processing and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

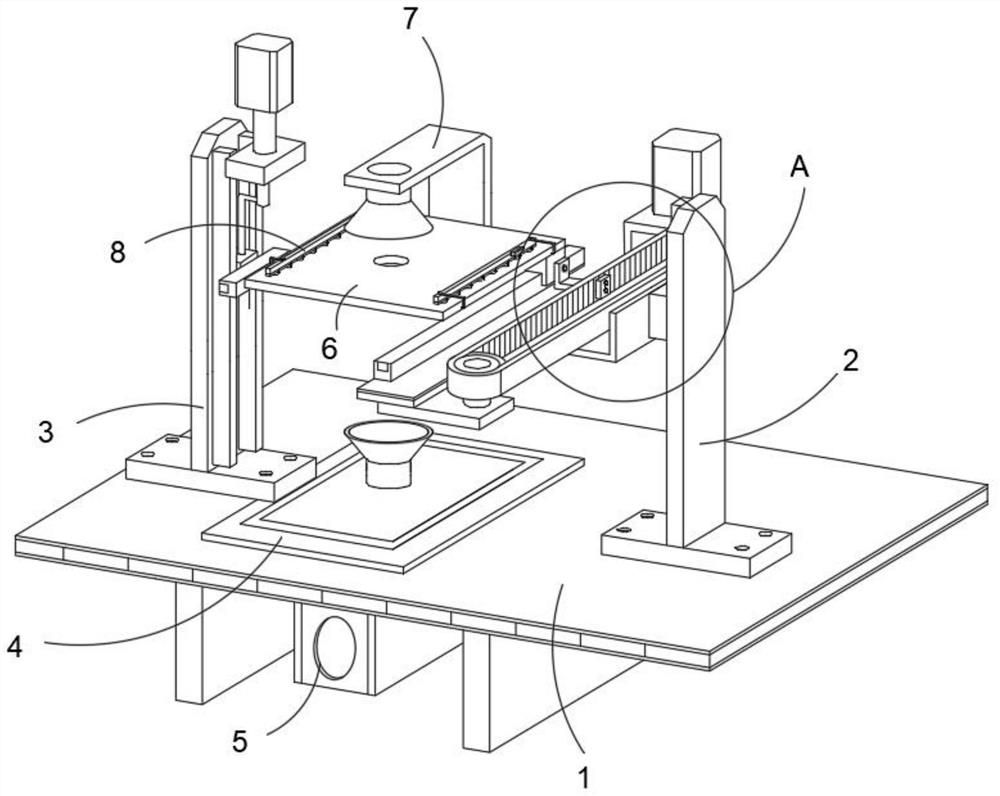

[0035] This embodiment provides the specific structure of the positioning plate on the detection platform, such as figure 1 with 5 As shown, the base plate 1 is equipped with a telescopic cylinder 5 for pulling textiles at its lower end, and a detection platform 6 for placing textiles is provided directly above the base plate 1, and a positioning plate 8 for positioning textiles is arranged on the detection platform 6.

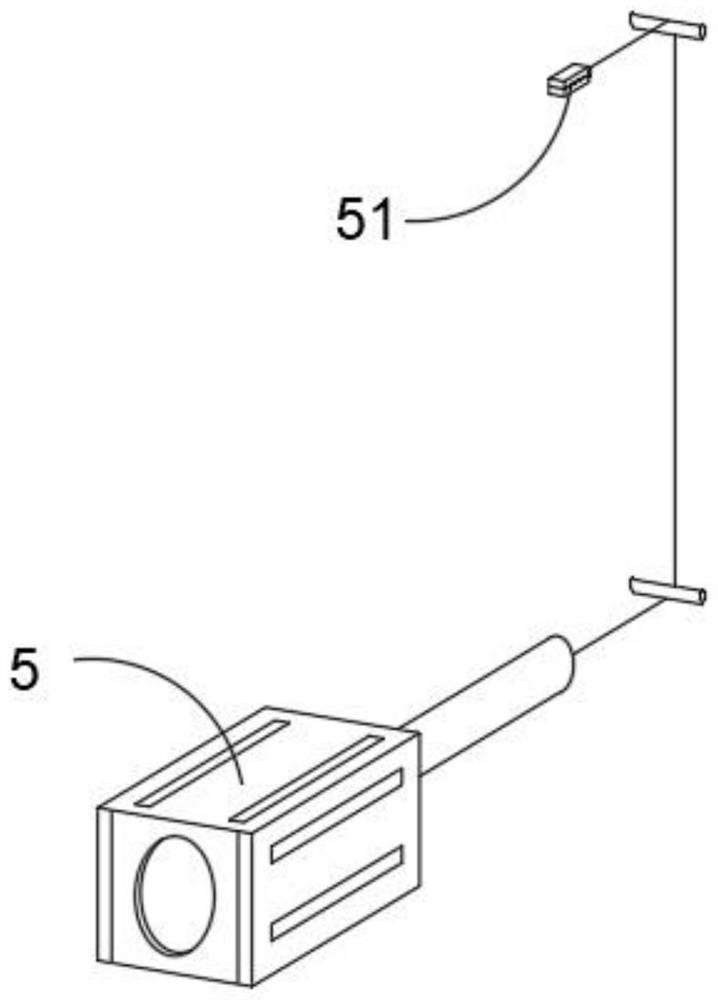

[0036] refer to figure 2 As shown, the end of the output shaft of the telescopic cylinder 5 is fixedly connected with a rope body, and one end of the rope body is connected with a clamp 51, and the clamp 51 is used to be clamped to one side of the textile; the telescopic cylinder 5 is opened to drive the clamp 51 moves backward, and the above-mentioned clamp 51 can adopt a clip or a buckle, only need to ensure that the position of the textile is stable.

[0037] refer to figure 1 with 2 As shown, the base plate 1 and the detection platform 6 are always ke...

Embodiment 2

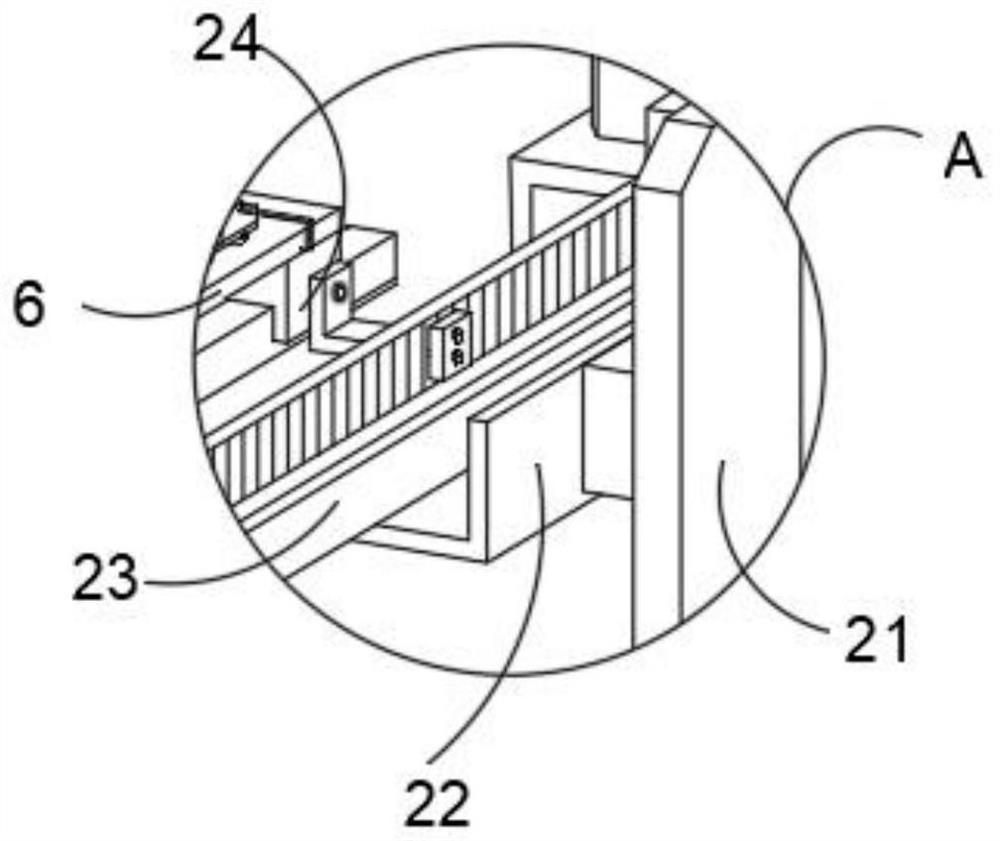

[0042] The present embodiment provides the concrete structure of feeding mechanism, as image 3 As shown, the feeding mechanism 2 is arranged on one side of the upper surface of the bottom plate 1, and the timing belt assembly 23 in the feeding mechanism 2 is used to drive the detection table 6 to move back and forth, and it can be driven when the timing belt assembly 23 rotates. Move back and forth.

[0043] Lifting mechanism 3, which is arranged on the other side of the upper surface of the bottom plate 1, and the lifting mechanism 3 includes a support plate, a No. 1 motor installed on the top of the support plate, and a guide rail frame for connecting the output end of the No. 1 motor and the detection platform 6; Textiles can be laid on the surface of the above-mentioned detection platform 6 .

[0044] refer to image 3 As shown, the feeding mechanism 2 also includes a support plate 21, a lifting plate 22 and a connecting plate group 24. The bottom end of the support pla...

Embodiment 3

[0053] The present embodiment provides the concrete structure of feeding mechanism, as figure 1 As shown, a cover assembly 4 is provided on the upper surface of the bottom plate 1 between the feeding mechanism 2 and the lifting mechanism 3 , and the cover assembly 4 is used to cover the detection light source 7 located below the detection platform 6 .

[0054] refer to Figure 4 As shown, the cover assembly 4 includes a bottom frame 41, an organ cover 42 and a top frame 43,

[0055] The bottom frame 41 is welded on the upper surface of the bottom plate 1, the top frame 43 is embedded in the preset frame groove on the top surface of the bottom frame 41, and is magnetically connected with the bottom frame 41, and the bellows 42 is used to connect the bottom frame 41 and the top frame 43 .

[0056] By adopting the above technical solutions:

[0057] The present invention involves the detection light source 7 above and below the detection table 6, which facilitates comprehensiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com