Detection apparatus and method for water mist formation resistance of cigarette packaging label paper

A technology of testing equipment and trademark paper, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

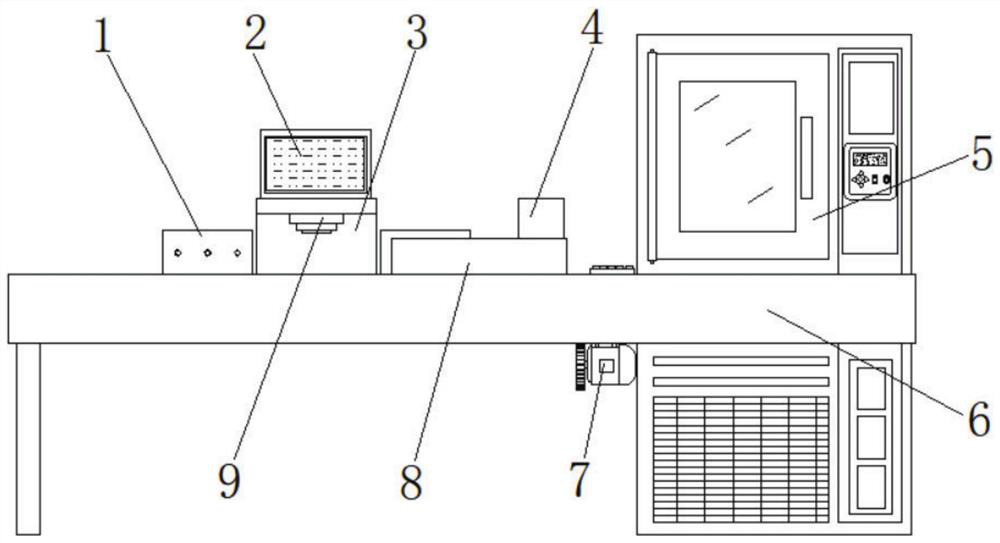

Examples

Embodiment 1

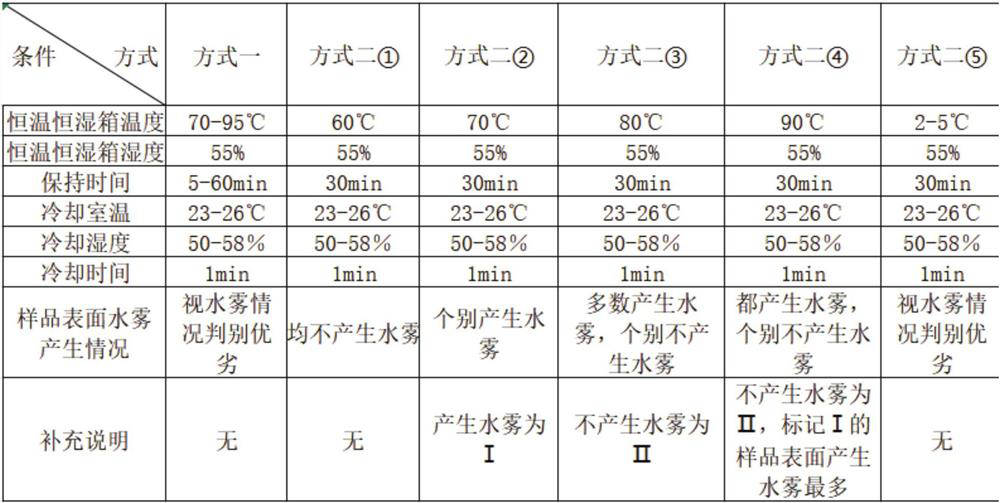

[0051] Embodiment 1, the detection effect is as follows:

[0052]

[0053] It can be seen that the detection method for the ability to form waterproof fog on the surface of trademark paper proposed by the application can be carried out by placing the trademark paper in a constant temperature and humidity chamber under the condition that the humidity is 55%, and by sequentially increasing the position of the sample in the constant temperature and humidity phase. The temperature method is to obtain the lowest constant temperature and humidity box temperature for the formation of water mist on the brand paper, and use this minimum temperature in the constant temperature and humidity box to characterize and compare the ability of different brand papers to form water mist.

Embodiment 2

[0054] Example 2, using the method proposed in this application to test the water-proof and fog-forming ability of the entire label paper surface.

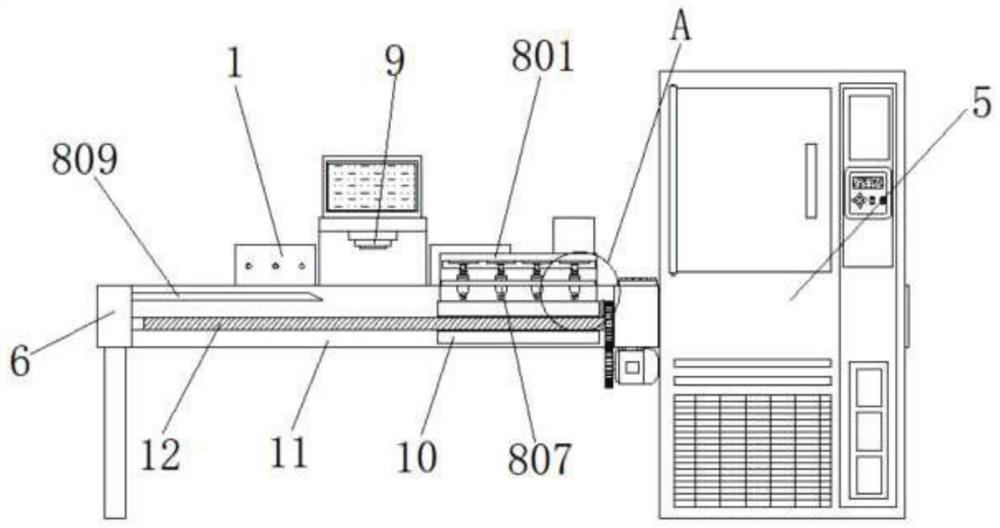

[0055] The first step is to paste the whole label paper on a piece of flat glass, with the printing side facing outward, and then cover it with cellophane, which is 20mm larger than the border around the outside of the sample, and seal the surrounding with tape so that the sample is tightly attached to the flat glass. The ambient temperature in the sample preparation room is controlled at 23-26°C, and the humidity is in the range of 50-58%. join image 3 .

[0056] In the second step, put the prepared sample into a constant temperature and humidity box at 90°C and a humidity of 55%. After placing it for 10 minutes, take it out of the constant temperature and humidity box. After 58% cooling for 1 minute, observe the formation of water mist on different parts of the label paper surface. After careful observation, it is found that ...

Embodiment 3

[0058] In Example 3, it was tested by the electric heating blower method, only the sample E obtained after the solidification of the varnish added with 2% wax powder did not form water mist, and the other samples all formed water mist.

[0059] Test with the method proposed in this application below:

[0060] The first step is to cut sample A, sample B, sample C, sample D and sample E into a size of 50×30mm, paste it on a piece of flat glass, with the varnish facing outward, and then cover it with cellophane, which is wider than the border around the outside of the sample Larger than 20mm, sealed with tape all around, so that the sample is tightly attached to the flat glass. The ambient temperature in the sample preparation room is controlled at 23-26°C, and the humidity is in the range of 50-58%. join figure 2 .

[0061] In the second step, put the prepared sample into a constant temperature and humidity box at 90°C and a humidity of 55%. After standing for 30 minutes, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com