Building comprehensive energy-saving management and control system based on environmental protection

A technology of environmental protection and management and control system, applied in the direction of cooling/ventilation/heating transformation, electrical equipment shell/cabinet/drawer, decoration through conduction and heat transfer, etc., can solve the problems of easy damage, misoperation, etc. The effect of falling off and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

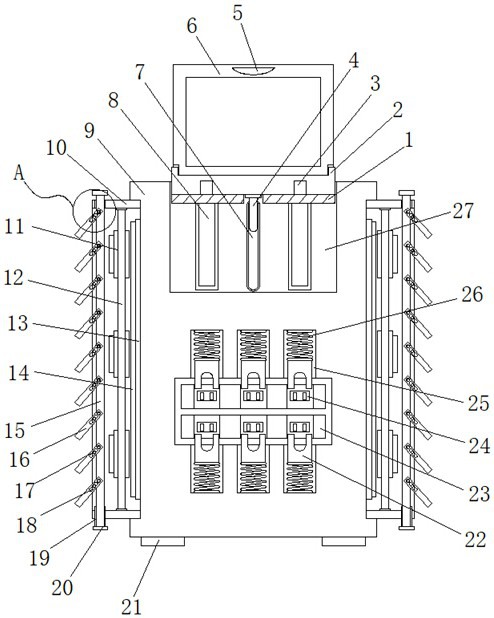

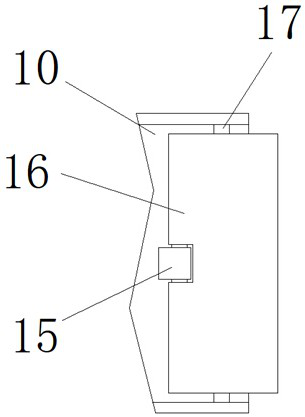

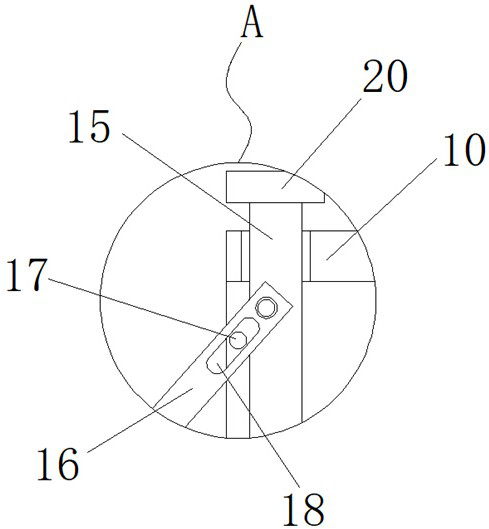

[0027] Example 1: See Figure 1-6 , a building comprehensive energy-saving management and control system based on environmental protection, including a chassis 9 and pillars 21, a set of pillars 21 are fixedly connected to both ends of the bottom of the chassis 9, and a storage slot 27 is embedded in the top of the chassis 9. A group of cooling chambers 10 are fixedly connected to both sides, and one end of the chassis 9 is inlaid with a groove 23;

[0028] The interior of the storage groove 27 is movably connected with the installation groove 2, and the two sides of the two ends of the storage groove 27 are respectively inlaid with a set of limit slide grooves 8, and the interior of the installation groove 2 is articulated with a control panel 6, and the tops of the two ends of the control panel 6 are inlaid respectively. There is a set of pull grooves 5, a set of buffer pads 1 are fixedly connected to both sides of the bottom of the installation groove 2, and a set of limit ...

Embodiment 2

[0032] Embodiment 2: a set of placement grooves 29 are inlaid on both sides of one end of the control panel 6, and the top of the placement groove 29 is hinged with a support plate 28;

[0033] The support plate 28 forms a flexible connection with the placement groove 29, and the width of the support plate 28 is less than the width of the placement groove 29 inside;

[0034] Specifically, such as Figure 4As shown, after the control panel 6 is separated from the inside of the storage groove 27, the support plate 28 at one end of the control panel 6 is extracted from the inside of the placement groove 29, and the bottom end of the placement groove 29 is placed on the top of the cabinet 9, which can realize The control panel 6 is supported to facilitate the operation of the staff;

Embodiment 3

[0035] Embodiment 3: The bottom end of the control panel 6 is fixedly connected with the data line 4, and one end of the receiving groove 27 is inlaid with a through groove 7, the through groove 7 communicates with the inside of the chassis 9, and the data line 4 runs through the installation groove 2 and the through groove 7 And extend to the inside of the chassis 9;

[0036] Specifically, such as figure 1 and Figure 5 As shown, while the control panel 6 is moving, the data line 4 used to connect the control panel 6 to the internal components of the device moves inside the through groove 7, which can protect the data line 4 and prevent the data line from being damaged when the control panel 6 moves. 4 damage;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com