Electrode body, electrolytic capacitor provided with electrode body, and method for producing electrode body

An electrolytic capacitor and electrode body technology, applied in the field of electrode bodies, can solve the problem of limited surface expansion of cathode foil, and achieve the effect of high electrostatic capacitance and stable electrostatic capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

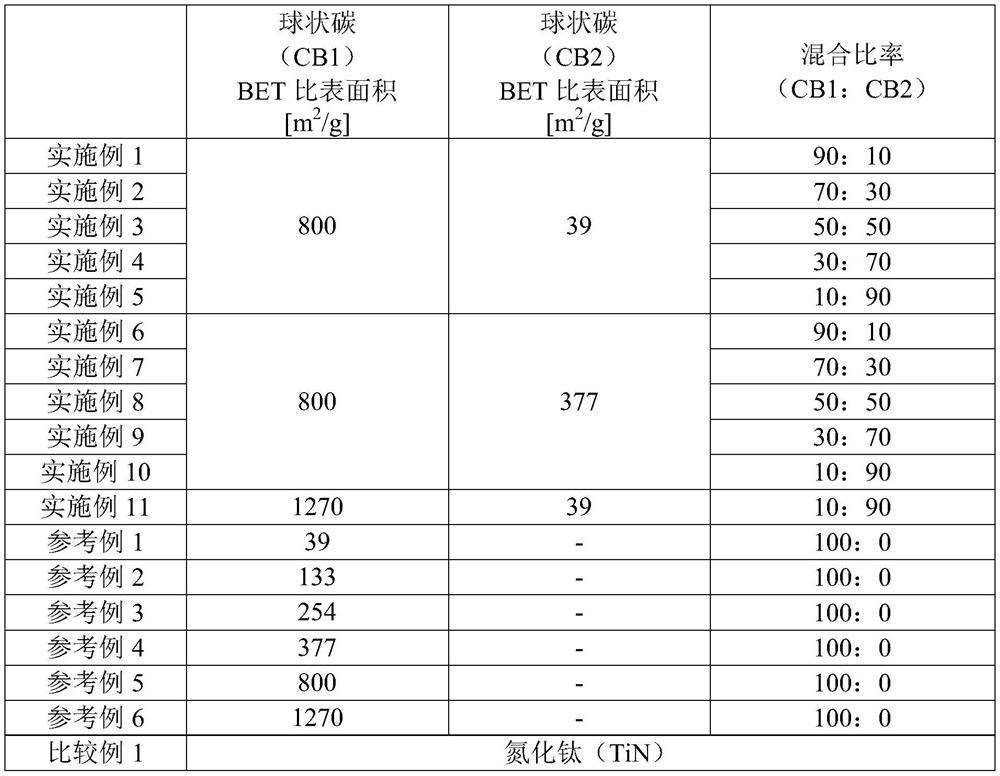

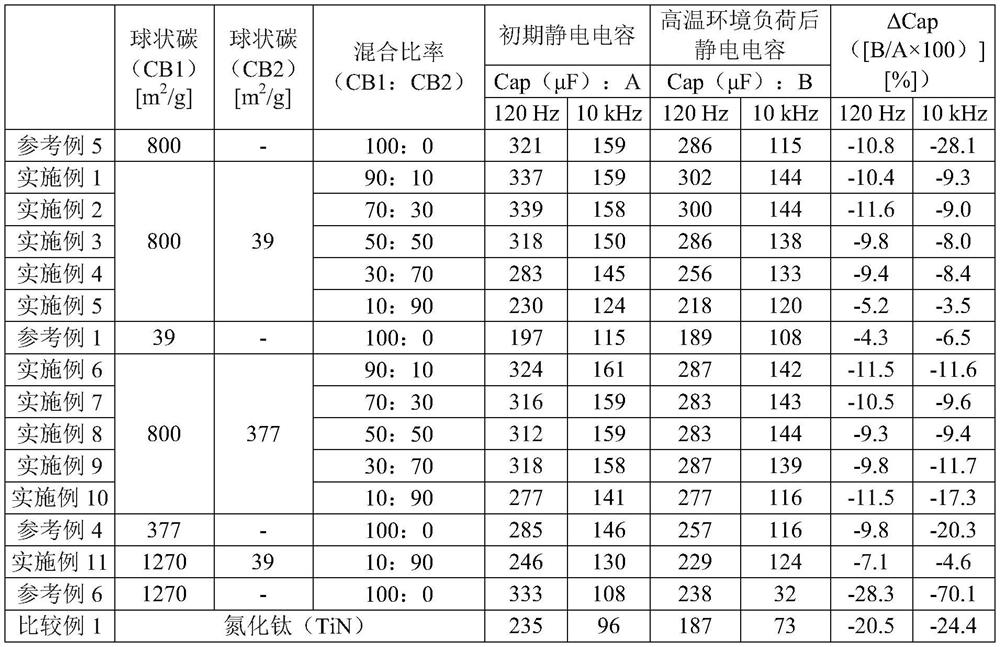

[0063] Hereinafter, the present invention will be described in more detail based on examples. In addition, this invention is not limited to a following Example. First, the electrolytic capacitors of each of the Examples, each of the Reference Examples, and Comparative Example 1 were produced in the following manner based on the embodiment of the lamination unit.

[0064] The general procedure for making electrolytic capacitors is as follows. First, regarding the cathode body, a carbon material was added to a CMC-Na aqueous solution as an aqueous solution containing a dispersant. The aqueous solution containing the dispersant contained 1.67 wt% of CMC-Na relative to the entire aqueous solution excluding the carbon material. After adding the carbon material, as a dispersion process, the aqueous solution was stirred for 3 minutes at 2000 rpm using a mixer (defoaming and stirring Taro, Xinji (Thinky) Co., Ltd.), and then the mixer (defoaming and stirring Taro, Xinji (Thinky) Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com