Method of producing electrolytic capacitor

A technology for electrolytic capacitors and manufacturing methods, which is applied in the direction of electrolytic capacitor manufacturing, electrolytic capacitors, capacitor manufacturing, etc., and can solve the problems of increased leakage current, inability to fully suppress the cracking of the dielectric layer, and the crystallization of the dielectric layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in more detail based on specific embodiments. However, the present invention is not limited to the following embodiments, and can be implemented with appropriate changes within a range that does not change the gist.

[0027] (experiment 1)

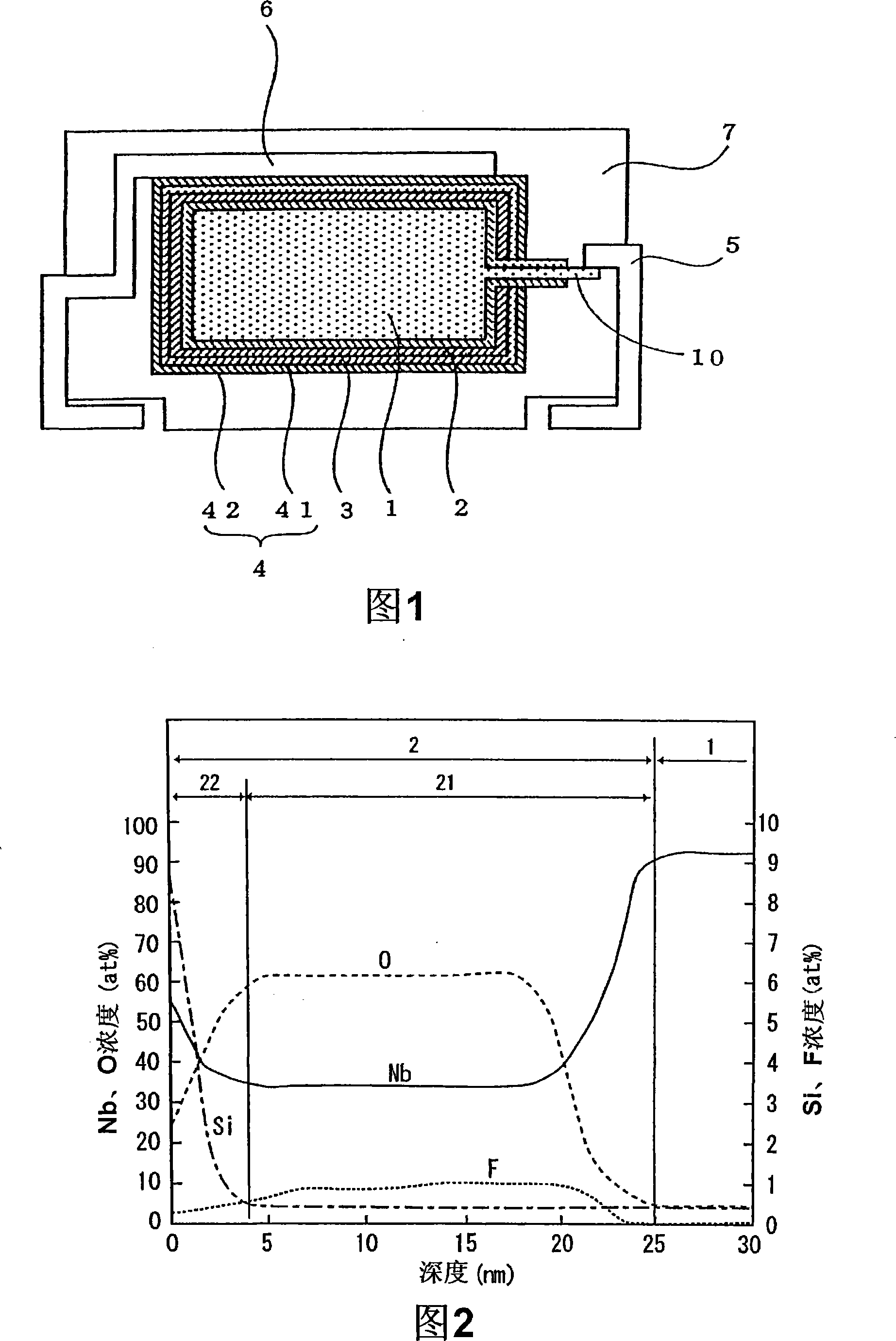

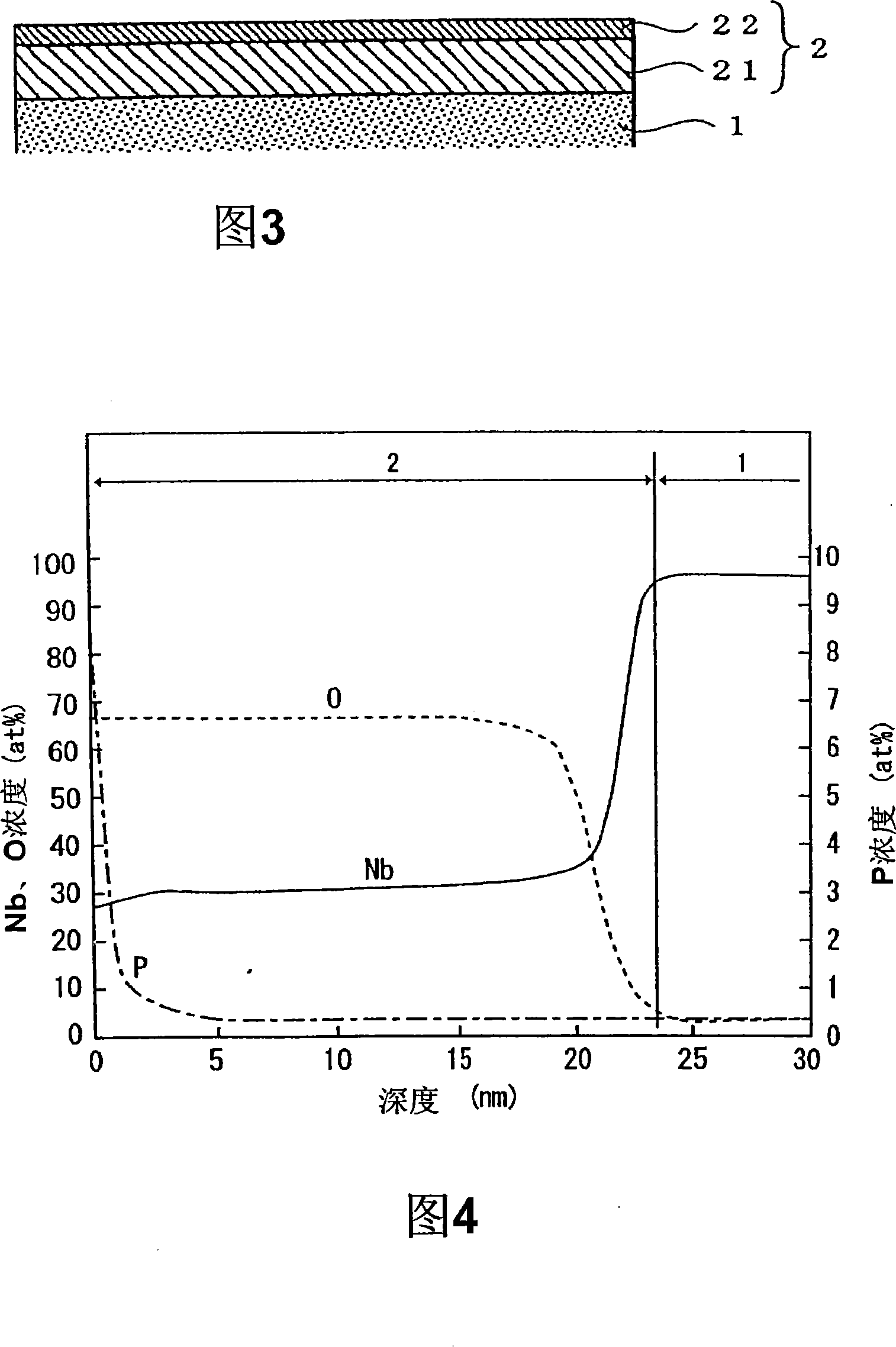

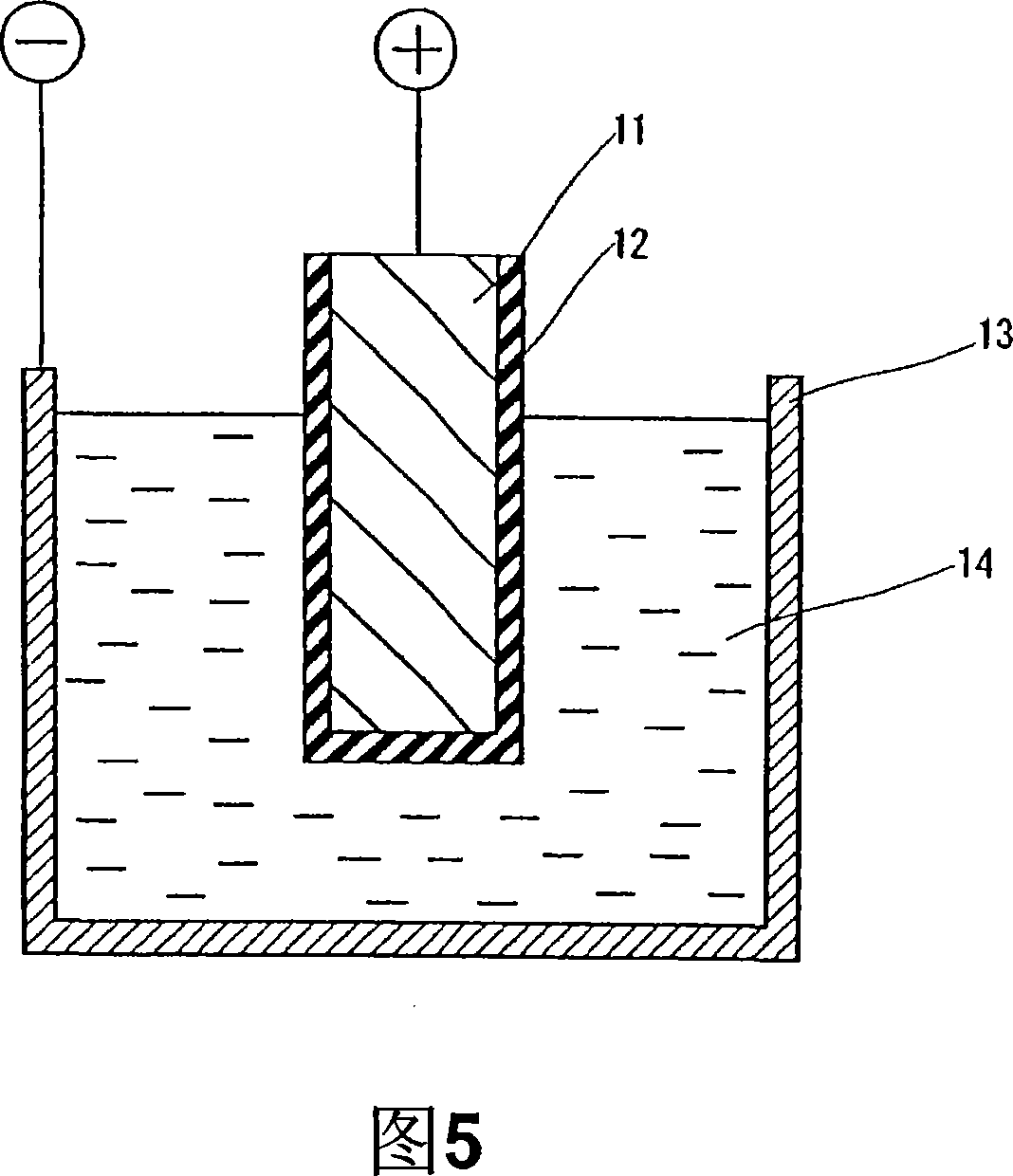

[0028] In Experiment 1, the anode was anodized using an ammonium hexafluorosilicate aqueous solution, thereby forming a dielectric layer. FIG. 1 is an explanatory cross-sectional view of a solid electrolytic capacitor fabricated in Experiment 1. FIG. Referring to FIG. 1 , a method for manufacturing the solid electrolytic capacitor produced in Experiment 1 will be described.

[0029] In Experiment 1, niobium metal powder with an average particle diameter of 2 μm was first sintered to produce an anode 1 made of a porous sintered body of niobium, and a lead wire 10 made of tantalum metal was extended from the anode 1 . Among them, niobium is an example of the "valve action metal" i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com