Metal oxide coated with conductive polymer, electrode for electrochemical device comprising it and method for producing metal oxide

A technology of conductive polymers and oxides, applied in battery electrodes, electrochemical generators, hybrid capacitor electrodes, etc., can solve the problems of low conductivity and difficulty in achieving high capacity, and achieve high capacity and excellent cycle stability , high output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

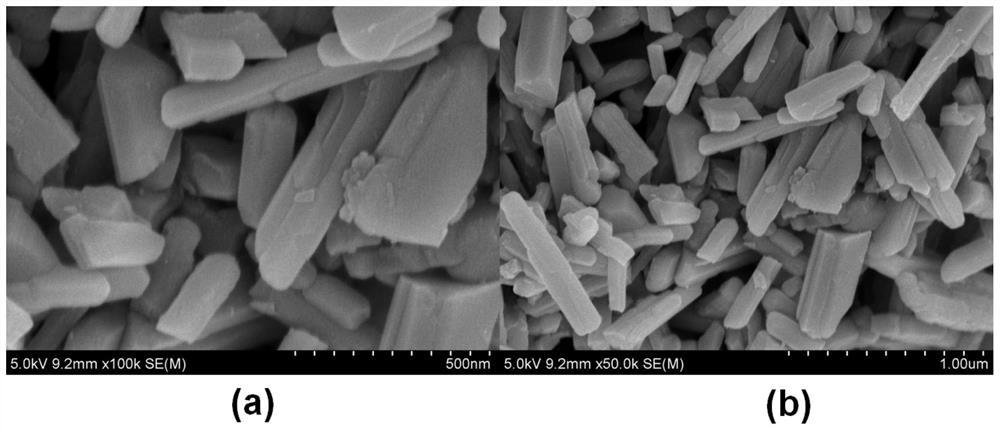

[0074] 0.2 g of cylindrical LiMn with a length of 500 nm and a diameter of 100 nm was prepared by dispersing in ethanol 2 O 4 . In another beaker, 0.012 mmol of pyrrole, 0.012 mmol of hydrochloric acid, and 50 mL of ethanol were stirred to protonate the pyrrole.

[0075] Then, the protonated pyrrole was added to LiMn 2 O 4and stir. At this time, the protonated pyrrole with positive (+) charge is adhered to LiMn with negative (-) charge by electrostatic attraction 2 O 4 on the surface.

[0076] Subsequently, FeCl was added as a polymerization initiator 3 , and the protonated pyrrole was polymerized at 25 °C for 6 h to 2 O 4 A metal oxide comprising a coating composed of a conductive polymer is formed on the surface of the .

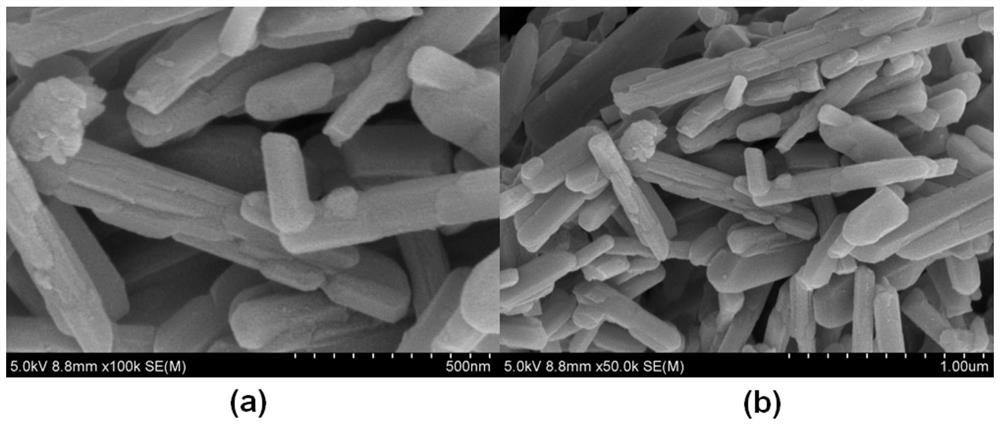

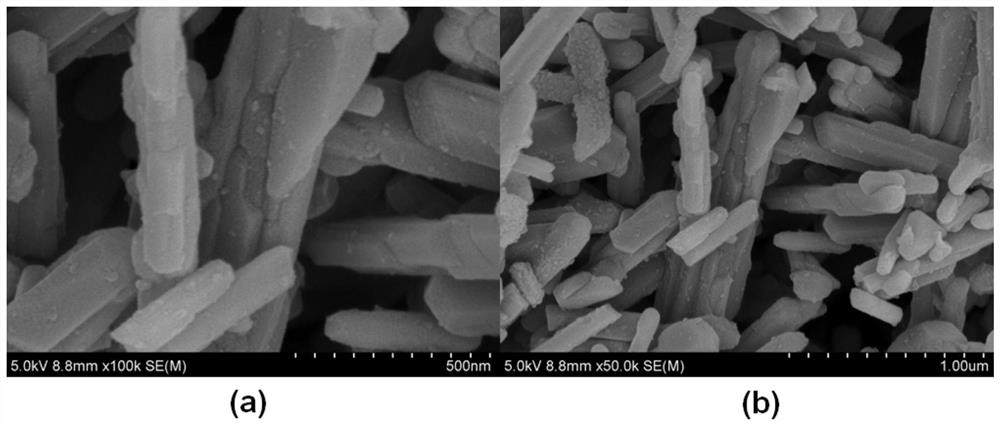

Embodiment 2 to Embodiment 6

[0078] The conductive polymer-coated metal oxides of Examples 2 to 6 were prepared in the same manner as in Example 1 except that the monomers and hydrochloric acid shown in Table 1 and their contents were used.

[0079] [Table 1]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com