Thermodynamic tea feeder

A feeder and thermal power technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve problems such as low efficiency, improve stability, improve efficiency, and reduce difficulty in use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

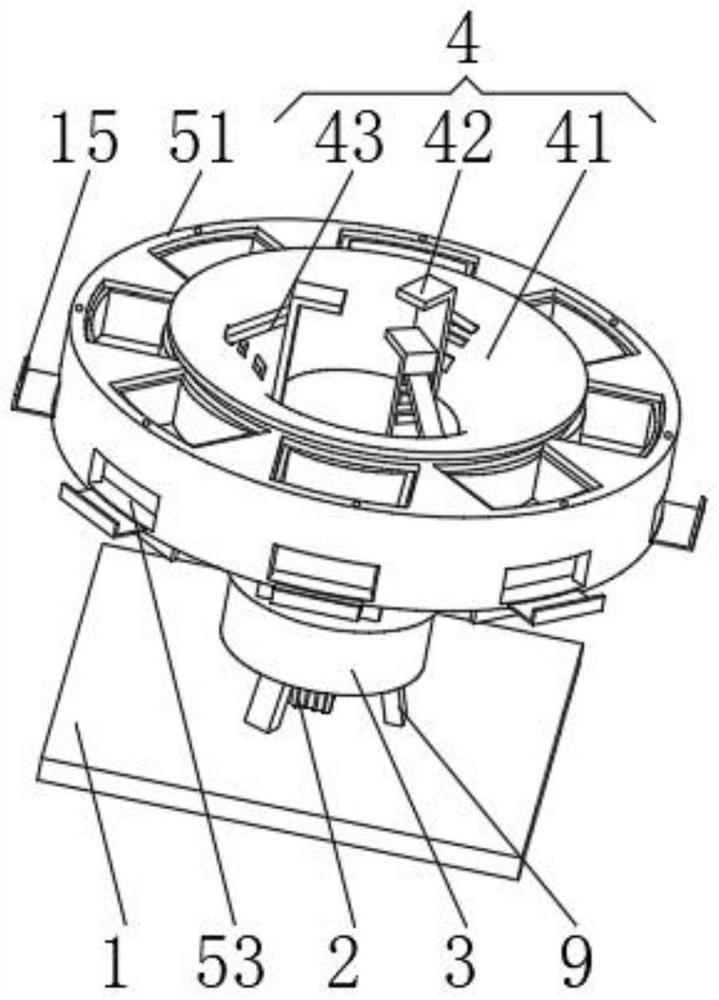

[0032] see Figure 1-4 , the present invention provides a technical solution: a thermal power tea feeder, comprising a bottom plate 1, a rotating motor 2 is installed on the top of the bottom plate 1, an inner drum 3 is installed on the output end of the rotating motor 2, and an inner drum 3 is installed on the outside of the inner drum 3 Settings are:

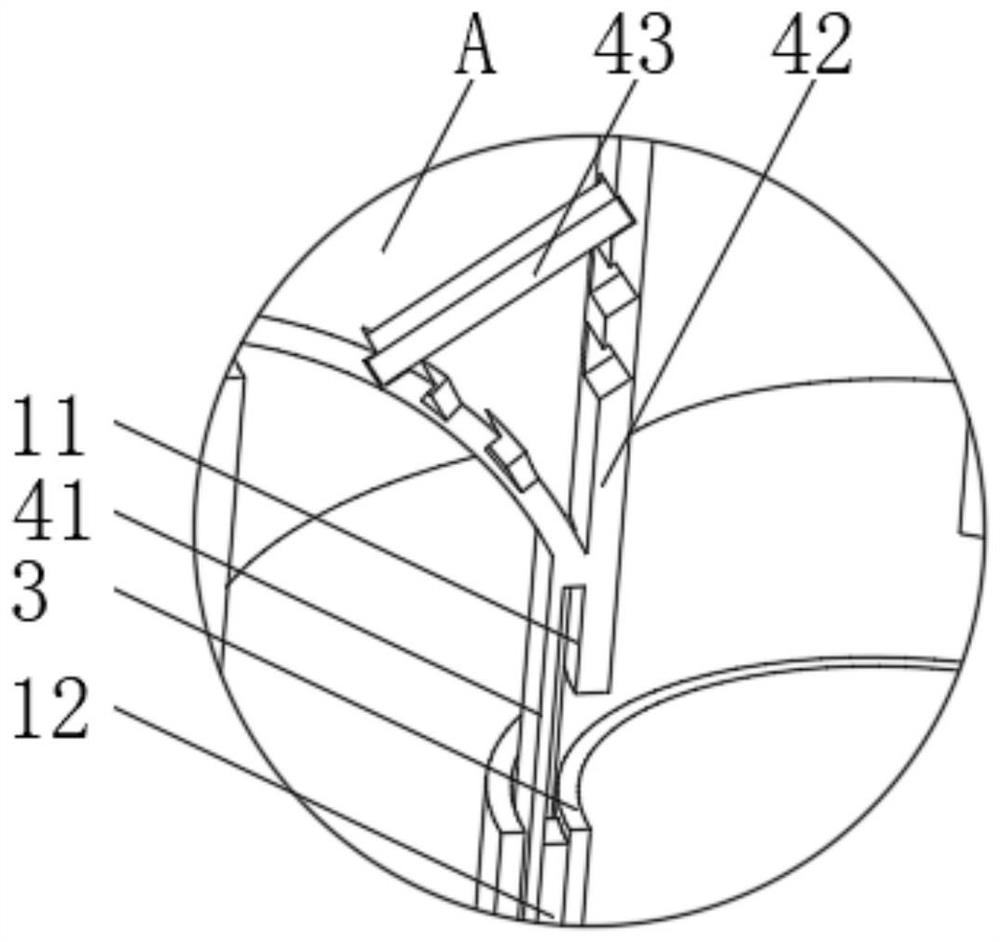

[0033] Adjusting device 4, the adjusting device 4 has a lifting outer frame 41, the top of the lifting outer frame 41 is trumpet-shaped, and the top of the lifting outer frame 41 is slidingly connected with a measuring folded plate 42, and the measuring folded plate 42 and the lifting outer frame 41 are installed There is a locking plate 43, and one side of the lifting outer frame 41 and the measuring folding plate 42 are provided with locking slots matching the locking plate 43;

[0034] Material holding device 5, the material holding device 5 has a material holding ring 51, the material holding ring 51 is fixedly connected ...

Embodiment 2

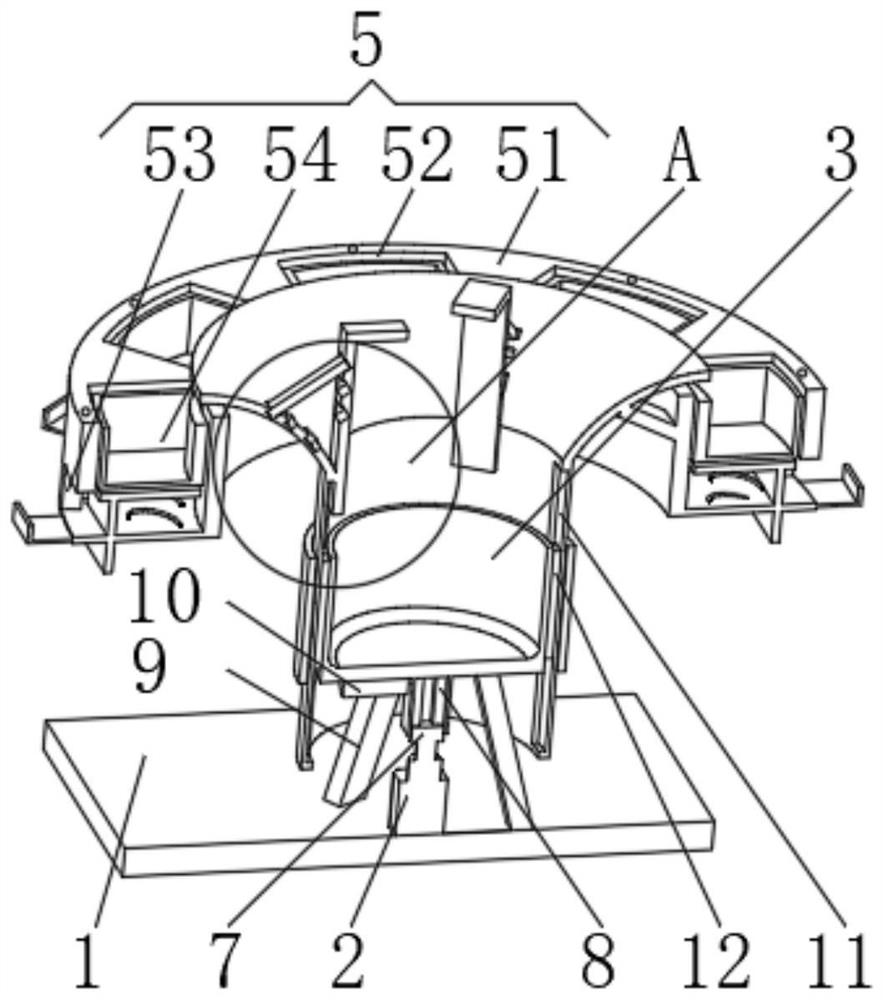

[0041] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, the output end of the rotating motor 2 is fixedly connected with a cross projection 7, and the bottom of the inner barrel 3 is fixedly connected with a limiter that matches the cross projection 7. As for the limit frame 8 , the top end of the cross projection 7 extends to the inside of the limit frame 8 and is slidably connected with the limit frame 8 .

[0042] The top of the bottom plate 1 is evenly equipped with a tilting rod 9, and one end of the top of the tilting rod 9 is slidably connected with the inner bucket 3 of the filling material, and the bottom of the inner bucket 3 of the filling material is fixedly connected with a guide arc block 10.

[0043] The top of the material holding ring 51 is evenly equipped with a longitudinal bar 16, and the top of the material holding ring 51 is provided with a screening groove suitable for the longitudinal bar 16, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com