Foaming tank mounting adapter for foaming gun

A foaming tank and foaming gun technology, applied in the field of foaming guns, can solve the problems of affecting the sealing of the sealing ball and the sealing gasket, the long time of the foaming gun being out of service, and the loss of activity of the conical spring, so as to achieve light and labor-saving operation , Simple structure, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

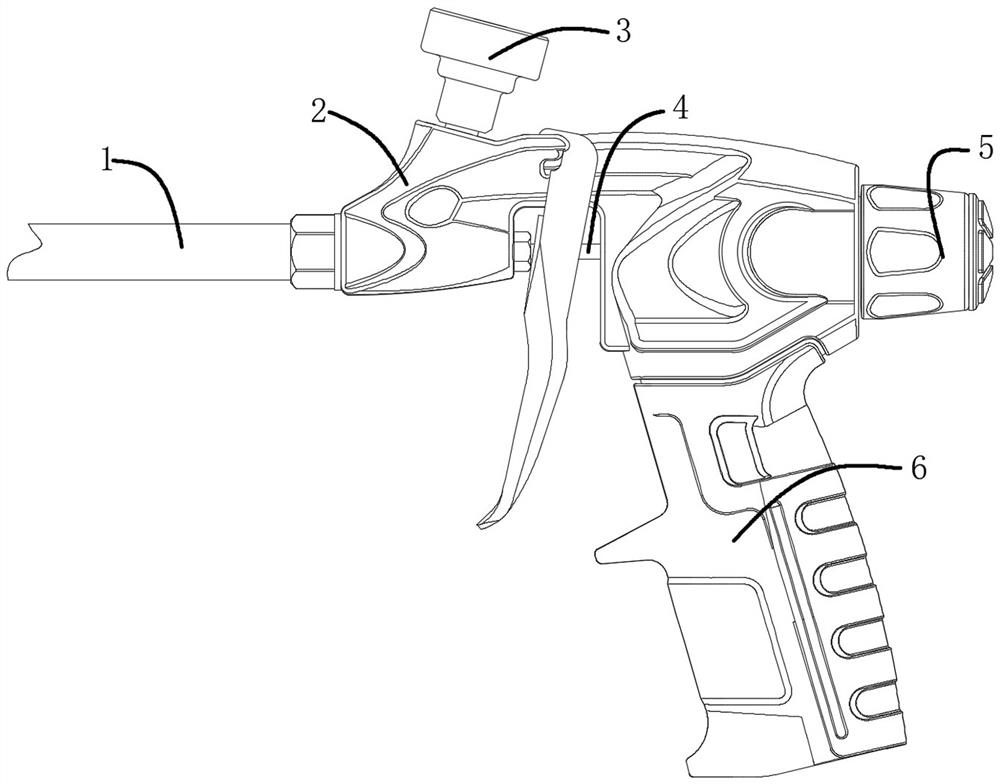

[0037] Combined with the drawings in the description, the mounting adapter is applied to the foaming gun to realize the installation of the foaming tank stored with the foaming agent. See figure 1 , the structure of the foam gun includes a gun body 2, a liquid chamber is provided in the gun body 2, and a gun barrel 1 is connected to the front side of the gun body 2, and the gun barrel 1 communicates with the inside of the liquid chamber, and the gun body 2 The rear side of the handle 6 is provided with, the inner end of the needle bar 4 stretches in the gun barrel 1, and the outer end of the needle bar 4 is connected with the flow regulating mechanism 5 on the gun body 2.

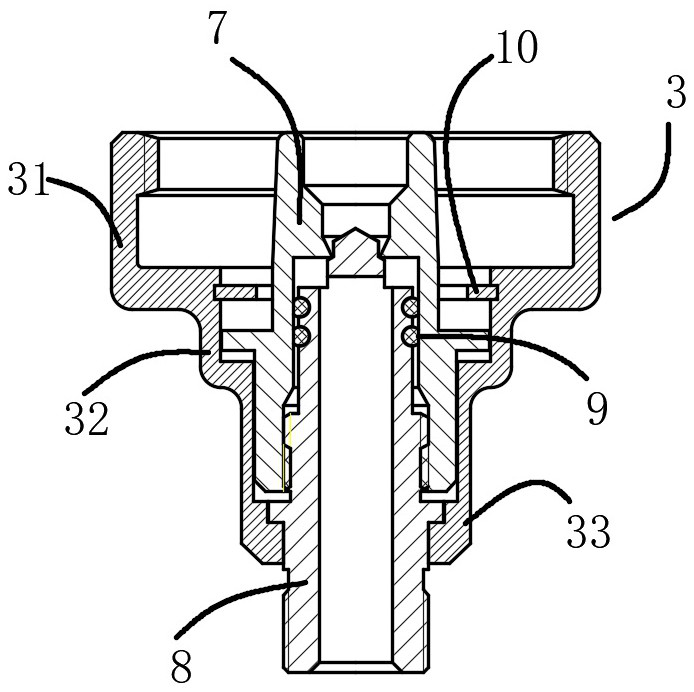

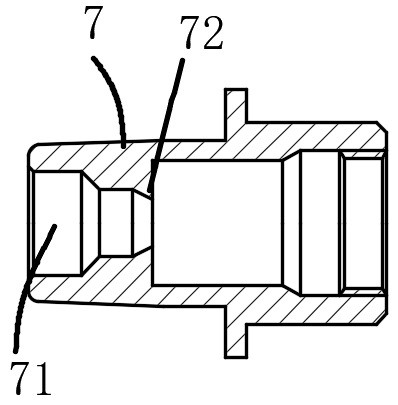

[0038] The structure of the mounting adapter includes a mounting frame 3, which is connected to the gun body 2 in a circumferentially rotating and axially limited manner. A positive internal thread is provided on the upper end side of the mounting frame 3, and a coupling head is provided on the outer end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com