Production system for inductor

A production system and inductor technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of cumbersome operation and low work efficiency, and achieve the effects of improving work efficiency, easy operation, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is attached Figure 1-9 The application is described in further detail.

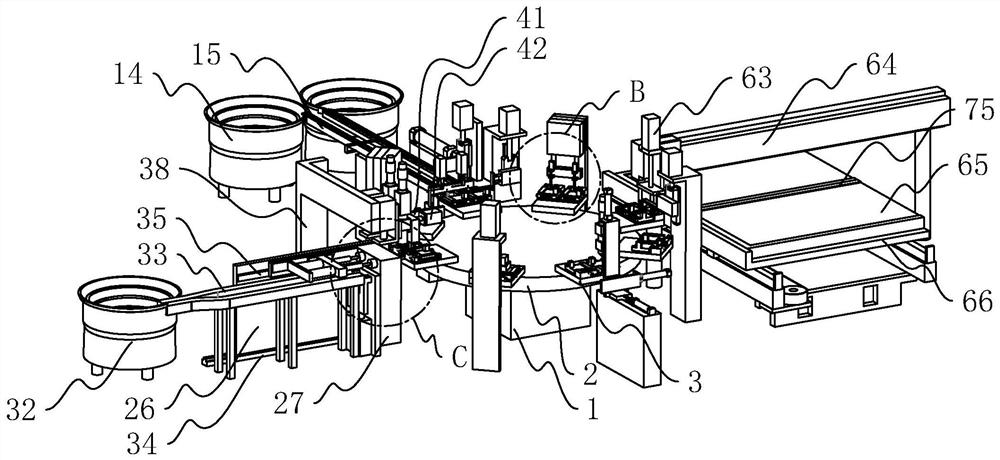

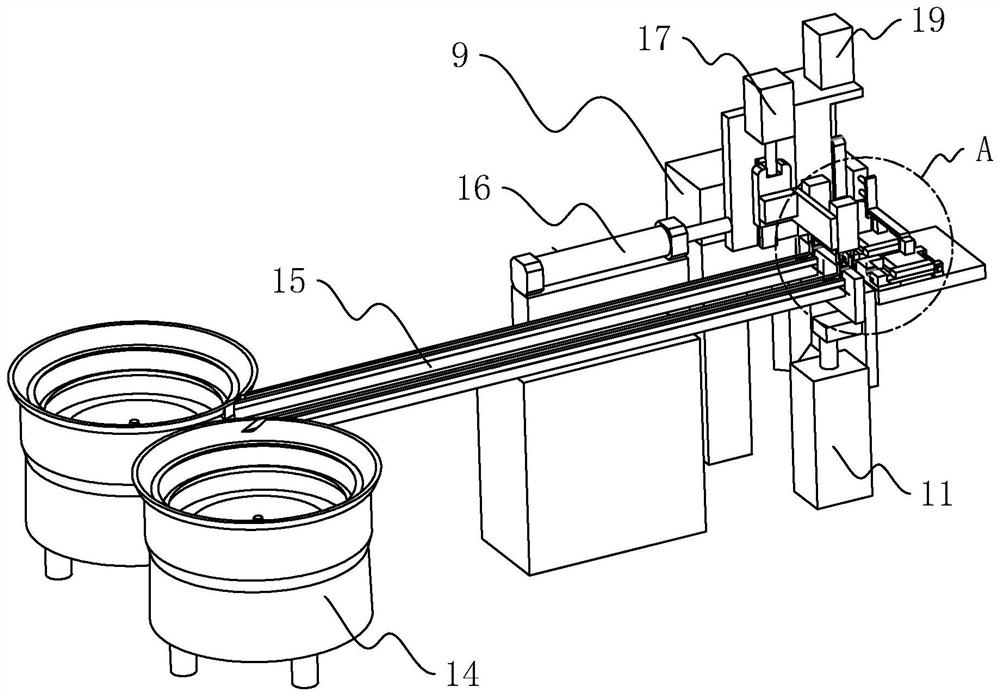

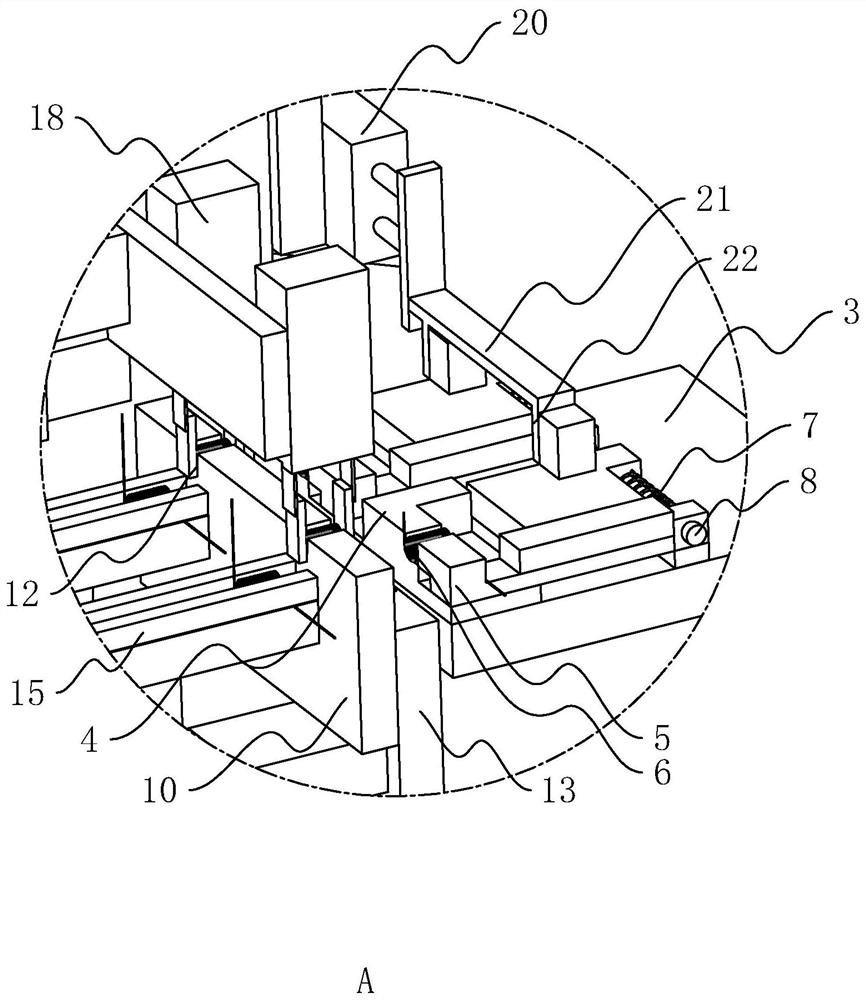

[0050] The embodiment of the present application discloses a production system for inductors. refer to figure 1 , The production system for inductors includes a feeding device, a coil winding feeding device, a magnetic core feeding device, an alignment device, a dispensing device and a receiving device.

[0051] Continue to refer to figure 1 , the discharging device includes a bearing assembly and a bearing rotating assembly, the bearing rotating assembly includes a rotating motor 1 vertically installed on the ground, the rotating disk 2 is in the shape of a circular plate, and the middle part of the rotating disk 2 is fixedly installed on the output end of the rotating motor 1, So that the rotating motor 1 drives the rotating disk 2 to rotate. The bearing assemblies are installed on the side of the rotating disk 2 away from the rotating motor 1 , and eight of them are evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com