Petroleum pipeline transfer vehicle capable of preventing weld joint collision

A technology for oil pipelines and transfer vehicles, which is applied to tubular objects, welding equipment, auxiliary welding equipment, etc., and can solve problems such as pipeline cracks and unfavorable welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

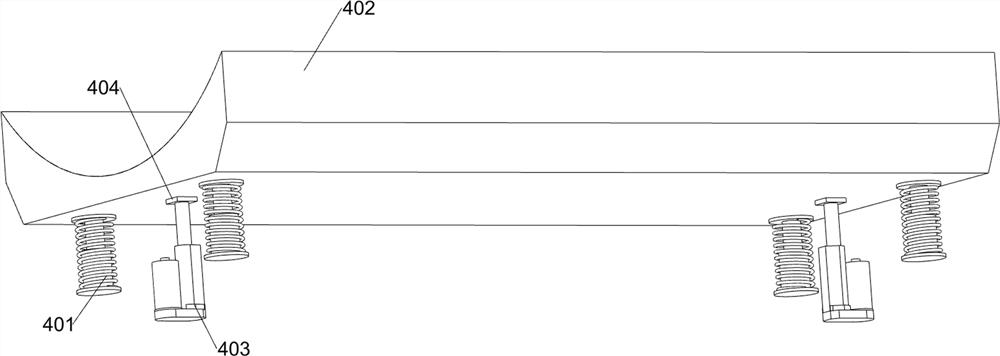

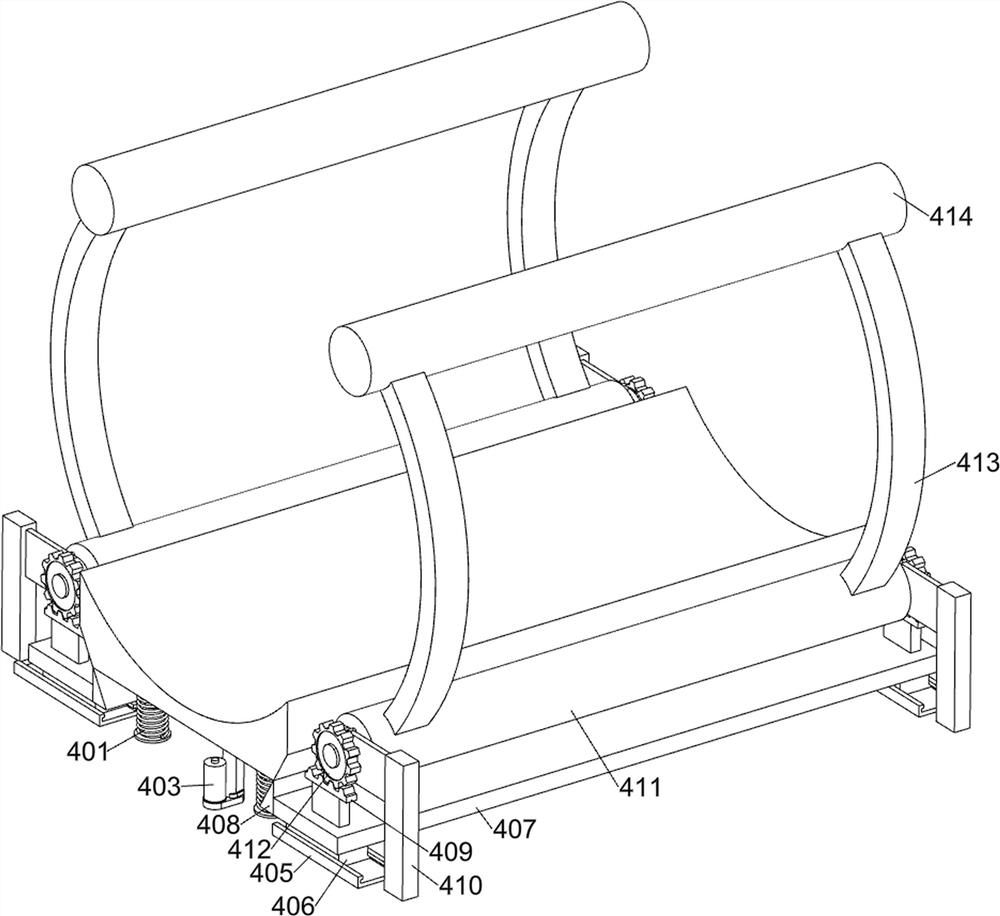

[0036] An oil pipeline transfer vehicle that prevents welding seams from colliding, such as Figure 1-2 As shown, it includes a mobile frame 1, a flip limit plate 2, a support frame 3, an anti-extrusion system and an anti-friction system; the left side of the top of the mobile frame 1 is connected with a flip limit plate 2 through an electric shaft; the mobile frame 1 There are two support frames 3 welded on the top; the anti-extrusion system is connected to the left side of the top of the mobile frame 1; the anti-extrusion system is used to limit the position of the pipeline and make the pipeline have room for vibration; two support frames 3 An anti-friction system is connected between the inner bottoms; the anti-friction system is used to hold the two ends of the weld seam of the pipeline when the pipeline is transferred and turbulent.

[0037] When using this equipment, control the equipment to move to the pipe to be transferred, the worker puts the pipe to be welded into t...

Embodiment 2

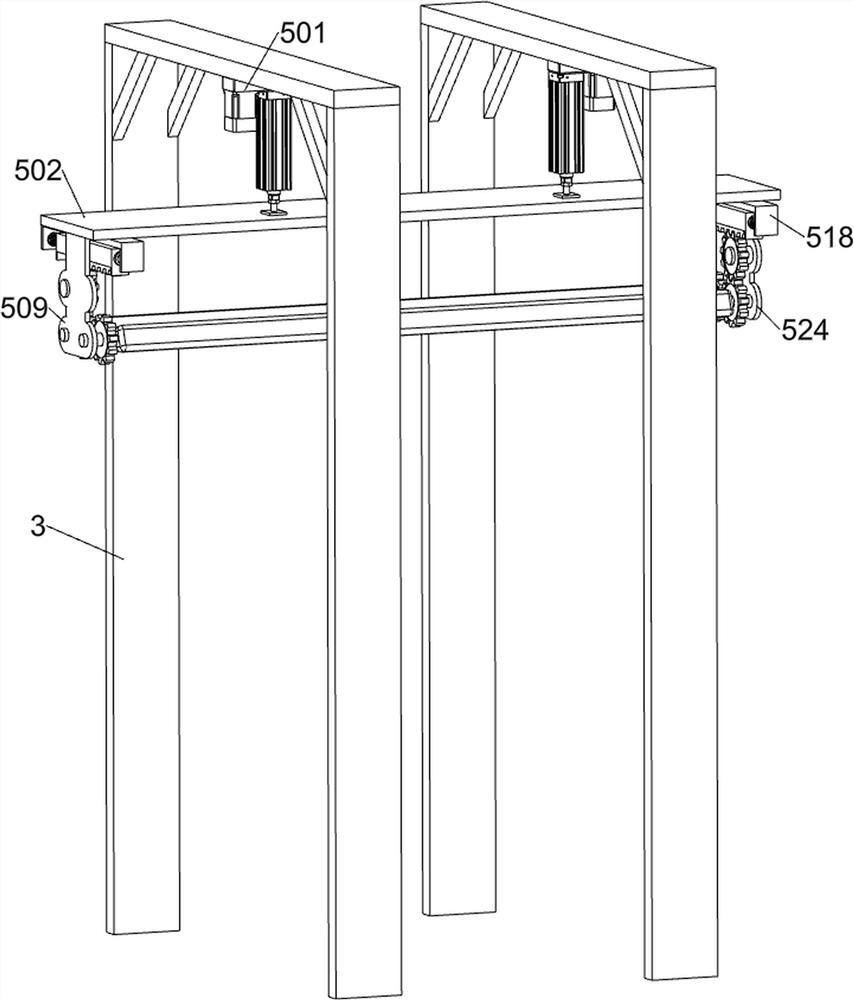

[0050] On the basis of Example 1, such as figure 1 and Figure 12-14 As shown, it also includes an upright system; the right side of the top of the mobile frame 1 is connected with an upright system; the upright system includes an electric slide rail 601, an electric slider 602, a third receiving plate 603, a mounting base 604, and a motor 605 , the fourth receiving plate 606, the second mounting part 607, the third mounting part 608, the infrared rangefinder 609, the fourth mounting part 610, the fifth mounting part 611, the first splint 612, the second electric push rod 613, the first Two splints 614 and a fixed plate 615; the bolt on the right side of the mobile frame 1 top is connected with two electric slide rails 601; two electric slide rails 601 tops are respectively slidably connected with an electric slide block 602; between the two electric slide block 602 tops There is a third bearing plate 603 fixedly connected between them; the top of the third bearing plate 603 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com