Vertical mill roller sleeve dismounting and mounting device and vertical mill roller sleeve dismounting and mounting method applying same

A technology of vertical grinding roller cover, disassembly method, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of time-consuming, laborious, inconvenient to disassemble the vertical grinding roller cover, etc., and achieves simple disassembly steps and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

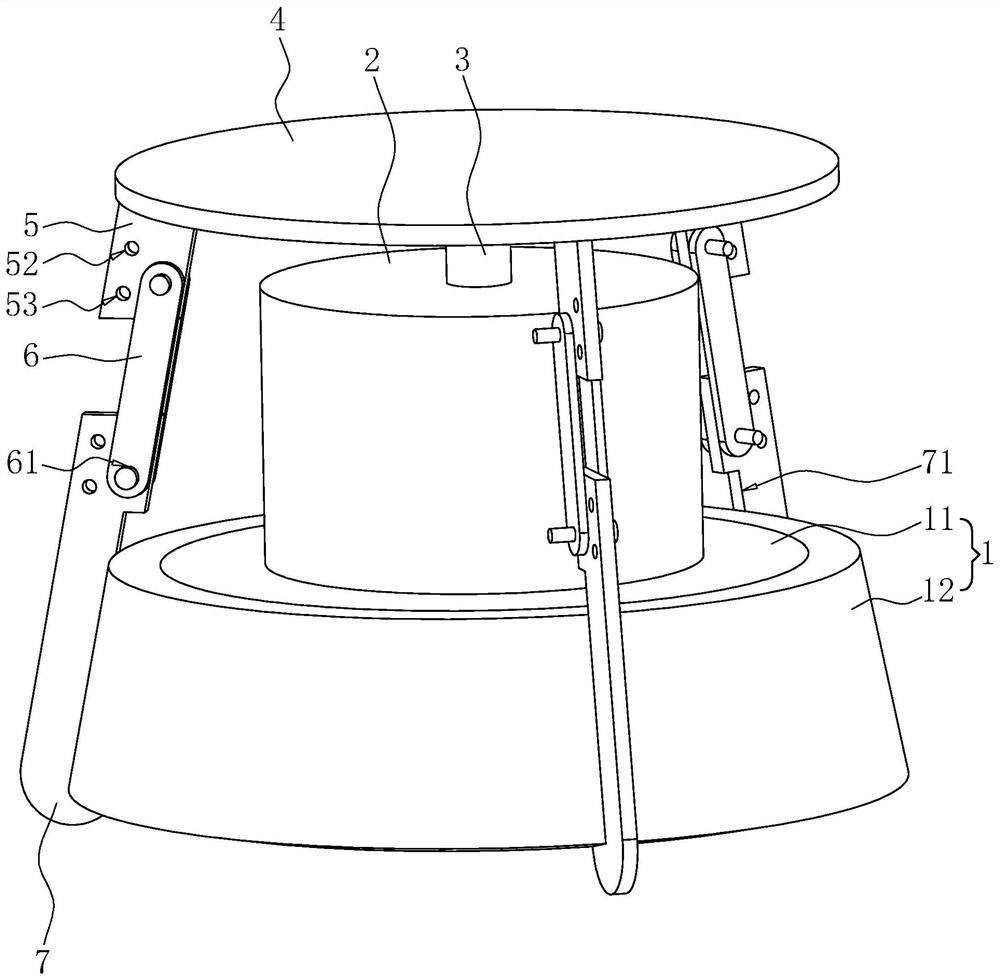

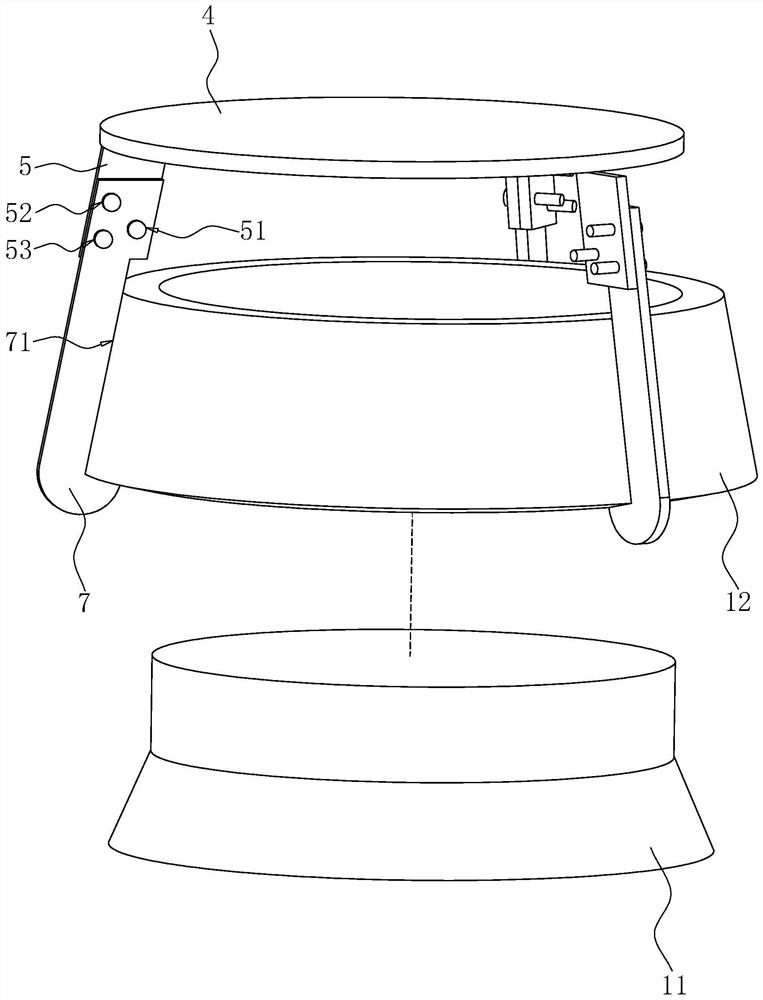

[0043] The following is attached Figure 1-2 The application is described in further detail.

[0044] The embodiment of the present application discloses a roller cover dismounting device for a vertical mill. refer to figure 1 , which is used to disassemble the vertical grinding roller sleeve 1, the vertical grinding roller sleeve 1 includes a grinding roller 11 and a grinding sleeve 12, the grinding sleeve 12 is sleeved on the outside of the grinding roller 11, and the gap between the grinding sleeve 12 and the grinding roller 11 surplus cooperation. The dismounting device includes a support frame 2 placed on the upper surface of the grinding roller 11 , the support frame 2 is a hollow cylinder, and the support frame 2 and the grinding roller 11 are placed coaxially. A jack 3 is placed on the upper surface of the support frame 2, and a connecting plate 4 is lapped on the upper surface of the jack 3, and the connecting plate 4 is cylindrical. The connection plate 4, the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com