Forklift headlamp mounting structure

A technology for mounting structures and headlights, which is applied in vehicle cleaning, lifting devices, and vehicle maintenance. It can solve problems such as damage, dust, headlight vibration, etc., and achieve clean and tidy surfaces, increase cushioning performance, and reduce vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

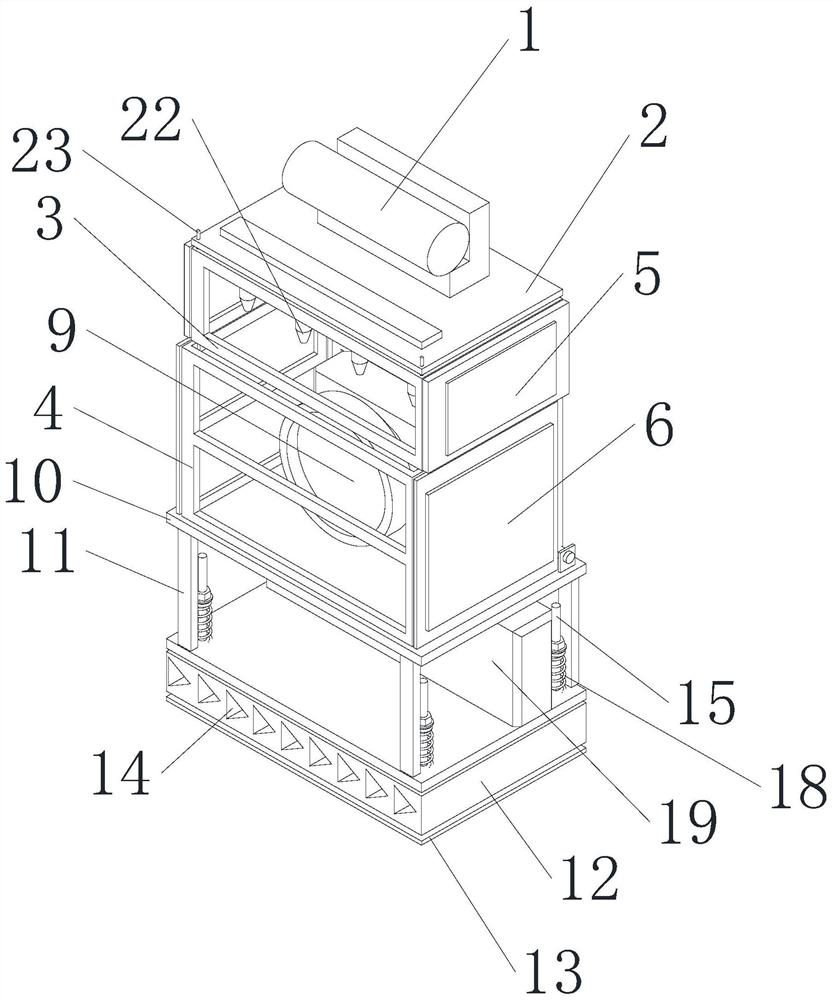

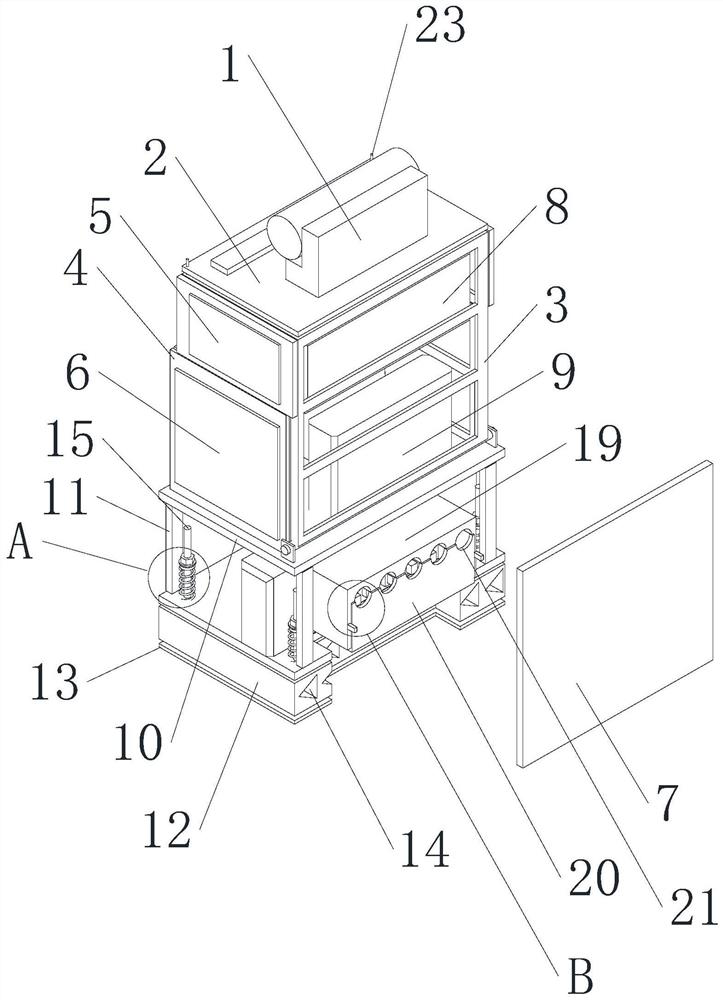

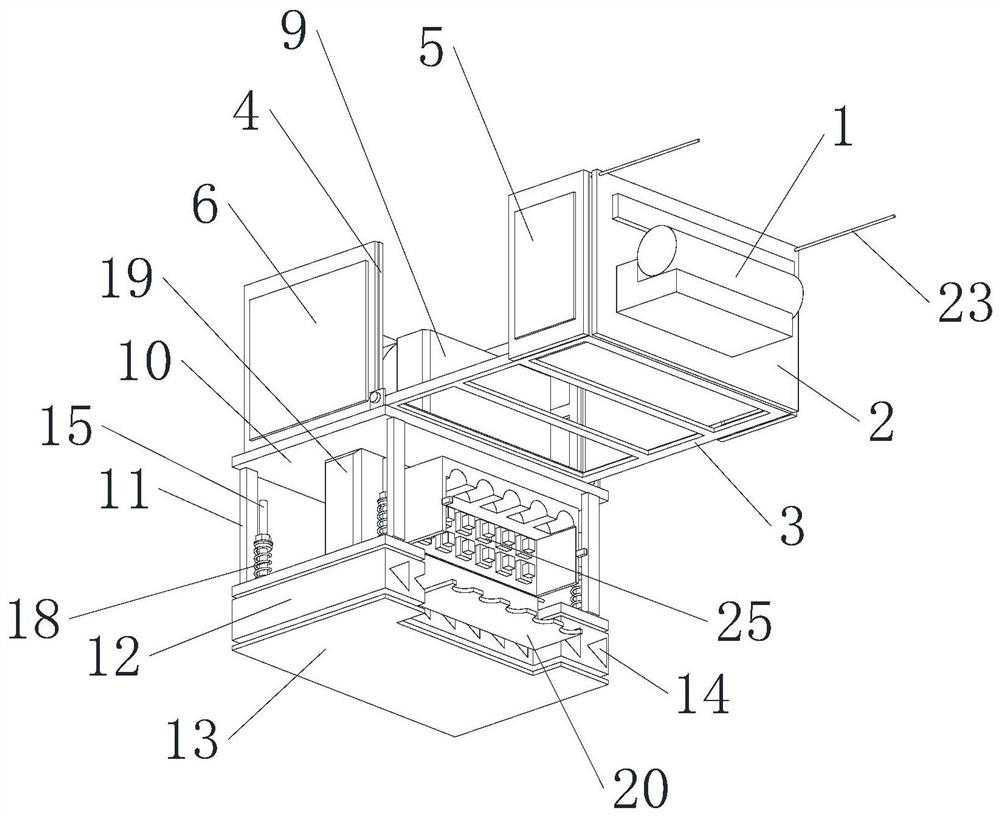

[0031] see Figure 1-7 , the present invention provides a technical solution: a headlight installation structure of a forklift, including a flip frame 3 and a support frame 4;

[0032] The overturning frame 3 is located at the upper right of the supporting frame 4, the lower end of the overturning frame 3 is rotationally connected with the lower right end of the supporting frame 4, and at least three high-pressure gas nozzles 22 are installed on the inner top of the overturning frame 3, and the lower end of the supporting frame 4 A pair of support plates 10 distributed up and down are provided, an elastic pad 12 is provided below the support plate 10 at the lower end, and a bottom plate 13 is provided at the lower end of the elastic pad 12;

[0033] The upper end of the support plate 10 at the upper end is fixedly connected to the lower end of the support frame 4, and the four corners of the upper end of the support plate 10 at the lower end are provided with interspersed rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com