Support structure, supporting equipment and coal mining complete equipment

A support structure and sub-frame technology, applied in mining equipment, mine roof support, earthwork drilling and mining, etc., can solve the problem of inconvenient entry of fully mechanized mining supports into small wellheads, so as to save coal mining costs, improve coal mining efficiency, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar parts or parts having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present application, and are not construed as limiting the present application.

[0058] First, introduce and explain the nouns involved in this application:

[0059] The roof refers to the exposed ore layer or rock layer at the top of the working face.

[0060] The bottom plate refers to the ground of the working surface.

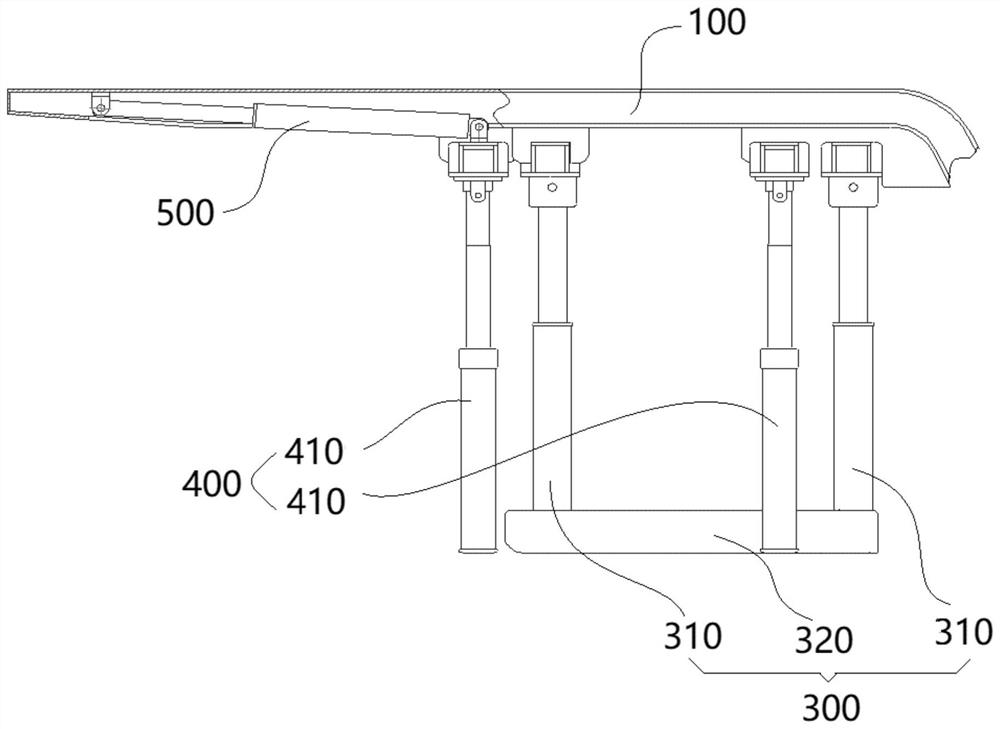

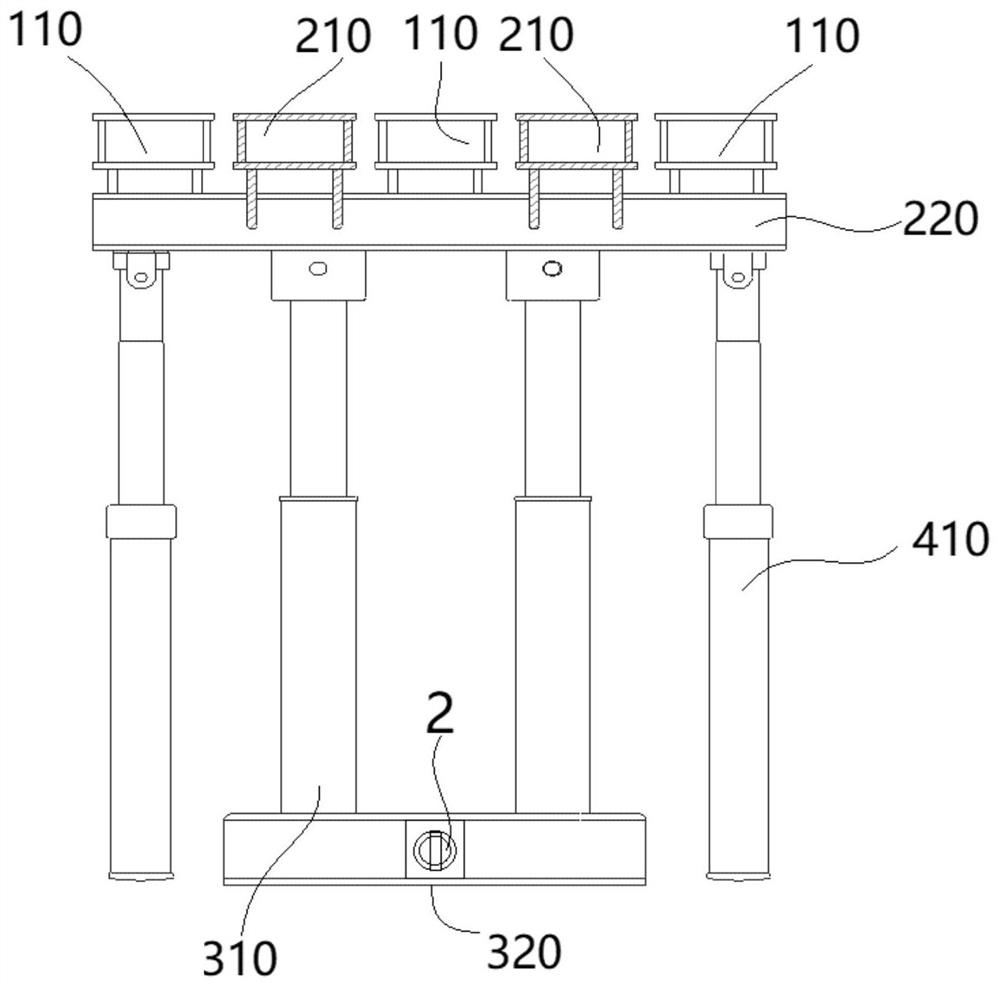

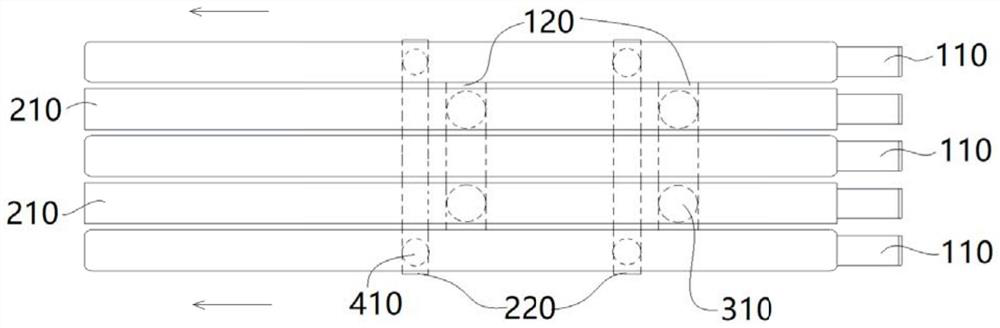

[0061] combine Figure 1 to Figure 5 As shown, the embodiment of the present application provides a support structure, including: a main roof beam support 100 and a secondary roof beam support 200 for alternately supporting the roof.

[0062] Below the main roof beam support 100 is provided a liftable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com