Portable automatic gas filling equipment

An automatic filling and portable technology, applied in mechanical equipment, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve the problems of complex operation, inconvenience for staff, single function, etc., and achieve simple operation and control, Adapt to a wide range and protect the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

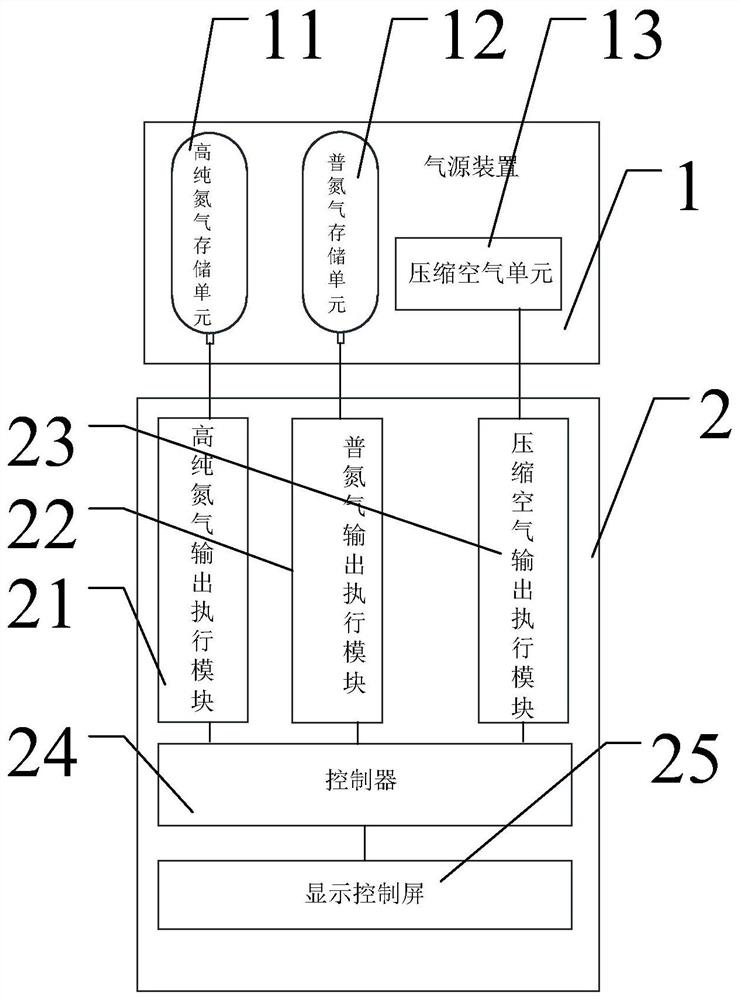

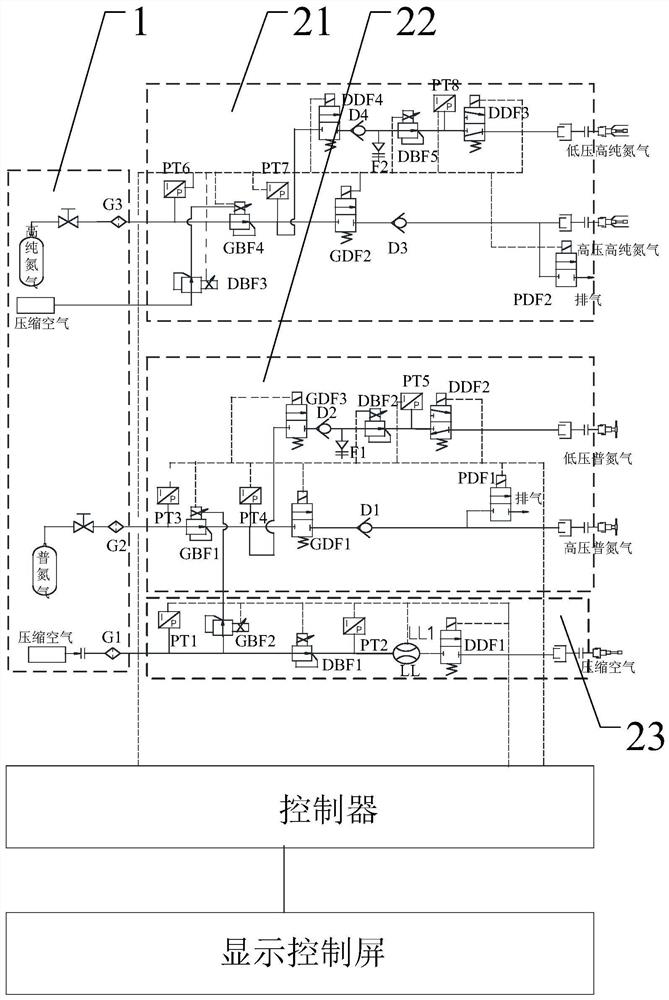

[0029] figure 1 It is a functional block diagram of a portable gas automatic filling device of the present invention, figure 2 It is a schematic diagram of the pipeline principle of a portable automatic gas filling equipment of the present invention. As shown in the figure, a portable automatic gas filling equipment includes a gas source device 1 and a gas filling control box 2 .

[0030] The gas source device 1 includes a high-purity nitrogen storage unit 11 , a common nitrogen storage unit 12 and a compressed air unit 13 . The gas outlet of the high-purity nitrogen storage unit 11 is provided with a high-purity nitrogen gas source output valve and a high-purity nitrogen high-pressure filter for storing 25MPa high-purity nitrogen. The gas outlet of the common nitrogen storage unit 12 is provided with a common nitrogen gas source output valve and a common nitrogen high-pressure filter for storing 15MPa common nitrogen.

[0031] The gas filling control box includes a high-pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com