Shutter type special equipment for wake flow protection of aircraft engine

An aircraft engine and louver-type technology, which is applied in the direction of reducing engine noise, can solve the problems of high local pressure of air, poor flow diversion effect, and inability to divert air, so as to achieve the effect of reducing noise, low noise, and favorable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

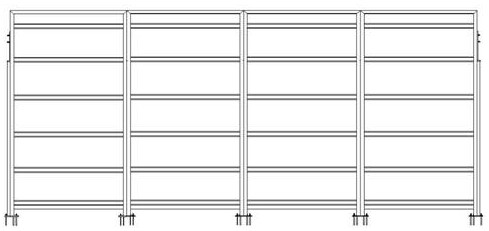

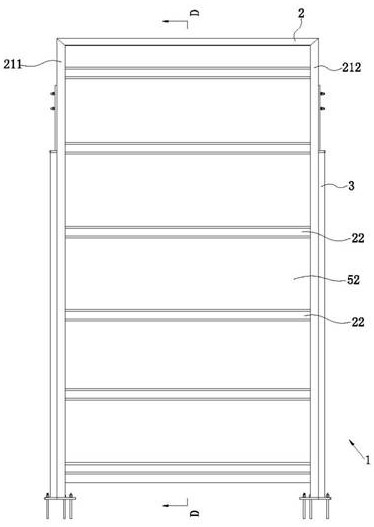

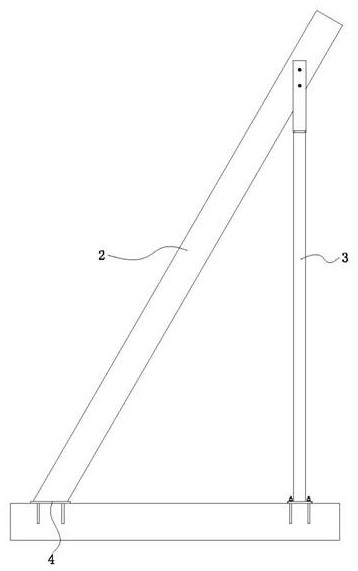

[0029] Such as Figure 1-7 Shown; a louver type aircraft engine wake protection special equipment, including more than one diversion noise reduction assembly 1; the diversion noise reduction assembly 1 includes a barrier assembly 2; barrier assembly 2 includes a barrier bracket and is installed on the barrier bracket There are more than two groups of diversion structures 22 . In this embodiment, there are seven groups of flow guiding structures.

[0030] Each group of guide structures 22 includes two first guide pieces 221; the first guide piece 221 is arranged in an arc shape upwards from the jet jet direction of the aircraft toward the direction perpendicular to the flow direction of the jet wake; the first guide piece 221 extends upwards with a second deflector 222; there is an angle α between the second deflector 222 and the jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com