Preparation method and product of egg white edible protein film

A technology of egg white and protein film, which is applied in the field of preparation of egg white edible protein film, can solve problems such as few studies, and achieve the effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

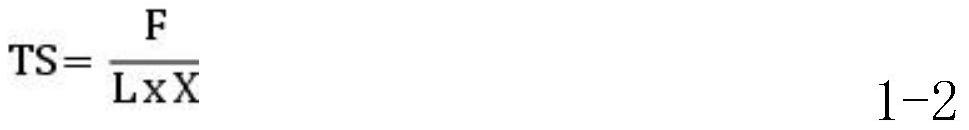

Method used

Image

Examples

preparation example Construction

[0037] 3, the preparation of membrane medium (for the conventional preparation method in the prior art):

[0038] Take an enzyme-labeled plate and remove the orifice plate, put the plastic wrap on the top surface of the enzyme-labeled plate, and stretch the corners of the plastic wrap to the bottom of the enzyme-labeled plate by hand, so that the plastic wrap and the side wall of the enzyme-labeled plate fit together , then fix the rubber band on the side wall of the enzyme label plate, flatten the plastic wrap on the top surface of the enzyme label plate, and finally glue the corners of the plastic wrap to the bottom surface of the enzyme label plate with tape, and place the enzyme label Flatten the corners of the plastic wrap on the bottom of the plate with tape to obtain a film-forming medium. When in use, put the film medium on a table or other flat surface to ensure that the top surface of the film-forming medium is level, then apply the film-forming liquid evenly on the ...

Embodiment 1

[0049] Preparation of egg white edible protein film:

[0050]Take two eggs, separate the egg whites (add 0 mL, 4 mL, 8 mL, and 16 mL of distilled water to each 20 mL of egg whites) and add them to a beaker, stir magnetically in an ice bath for 2 h, then centrifuge at 3500 rpm for 15 min to remove the precipitate. Heat 20mL of the supernatant in a 37°C water bath for 30min, add glycerin (glycerol concentration is 0g / L, 30g / L, 33g / L, 36g / L), stir magnetically for 15min, and place it in a 37°C water bath Heat in medium for 30min, add TG (enzyme activity 0U / g, 20U / g, 40U / g, 60U / g), stir with glass rod for 5min while adding, heat again in 37℃ water bath for 60min, take out the film-forming liquid Cool to room temperature.

[0051] Accurately absorb 2mL of film-forming solution, place it in a 10cm×8cm film medium, and spread it evenly. After two weeks, the apparent characteristics of the membranes were observed and the mechanical properties of the membranes were tested. When perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com