Pull rod device used for steel tapping machine and assembling method of pull rod device

A tie rod device and assembly method technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of thread length limitation, accelerated tapping rhythm, difficult manufacturing, etc., to increase overall strength, avoid breakage, and improve connection stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

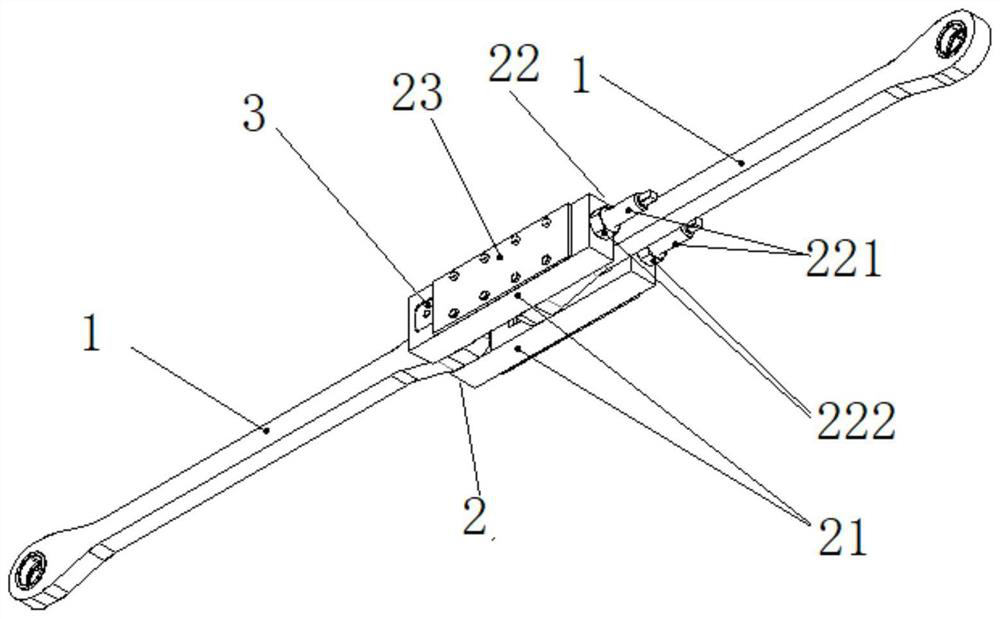

[0056] One end of the square frame plate 2-1 is connected to a bridging long plate 1 through a first connecting portion, and the other end of the square frame plate 2-1 is connected to another bridging long plate 1 through a second connecting portion; this connection method can When the second connecting groove 211 is a strip-shaped groove, the distance between the two bridging long plates 1 can be changed.

no. 2 example

[0058] One end of the square frame plate 2-1 is connected to a bridging long plate 1 through a first connecting portion, and the other end of the square frame plate 2-1 is also connected to another bridging long plate 1 through a first connecting portion; this connection method, The connection between the two bridging long boards 1 and the frame board 2-1 can be realized stably; with such a connection method, the connection between the bridging long board 1 and the square board 2-1 can be simplified, which facilitates the bridging of the long boards 1 assembly connection.

no. 3 example

[0060] One end of the square frame plate 2-1 is connected to a bridging long plate 1 through the second connecting portion, and the other end of the square frame plate 2-1 is also connected to another bridging long plate 1 through the second connecting portion; When the groove 211 is a bar-shaped groove, the present invention adopts such a connection method, which can realize the change of the distance between the two bridging long plates 1; The adjustment range of the tie rod device can be increased.

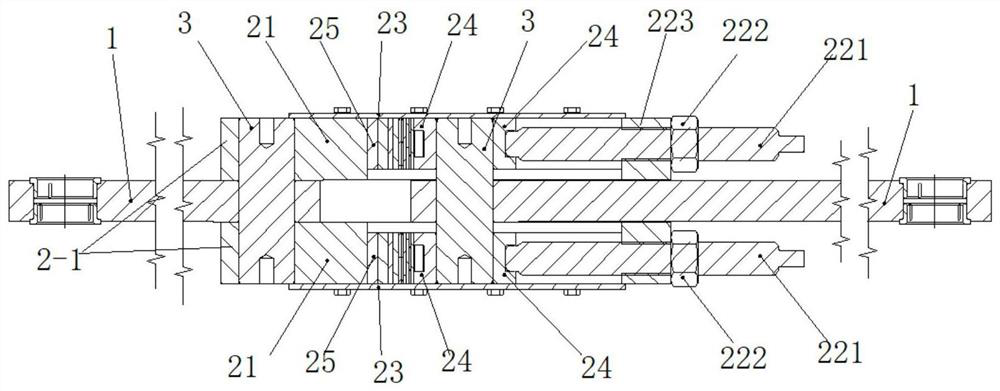

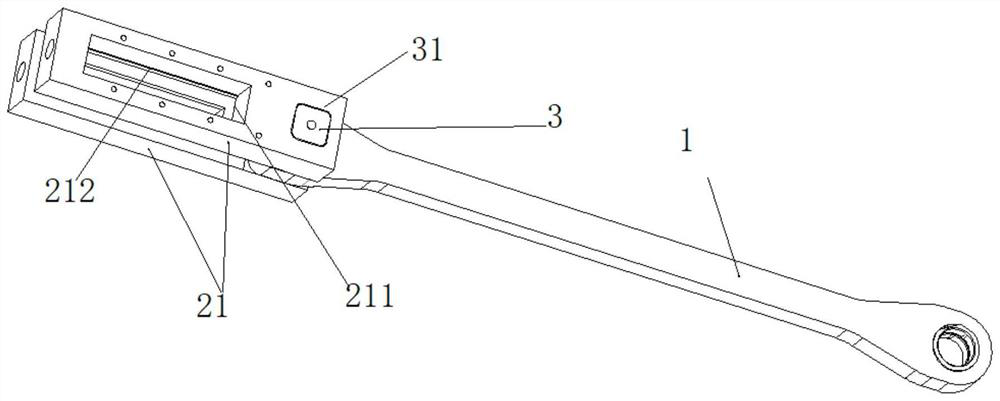

[0061] Further, in the present invention, the locking mechanism 22 includes a locking bolt 221 and a threaded hole 223 provided at the end of the frame plate 2-1, and the second connecting groove 211 connects with the frame plate through the threaded hole 223 2-1 The outer side is connected; the locking bolt 221 passes through the threaded hole 223 and is connected with the insertion prism 3 in the second connecting groove 211; in actual use, the locking bolt 221 in the locking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com