Novel cable surface defect detection device and detection method thereof

A defect detection and cable technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of uncomfortable detection, time-consuming and labor-intensive, etc., and achieve the effect of comprehensive detection, simple and convenient operation, and convenient positioning and placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

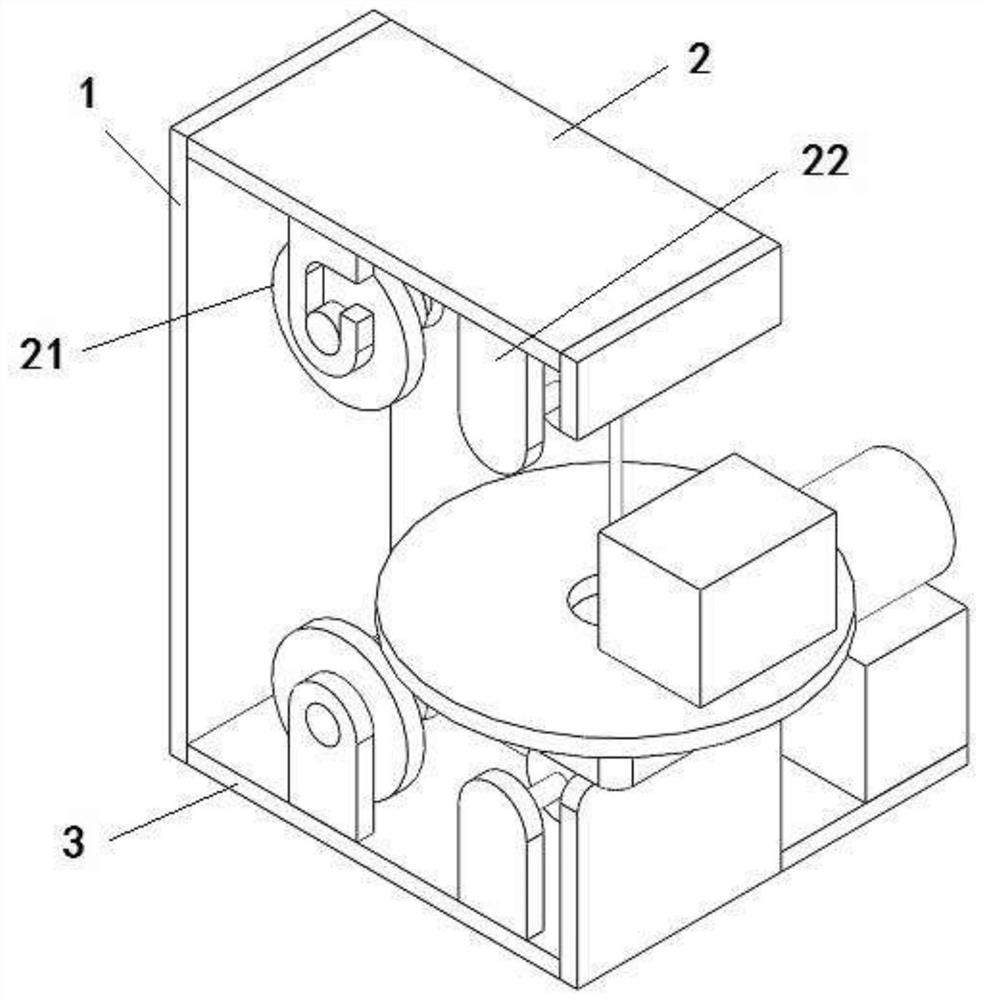

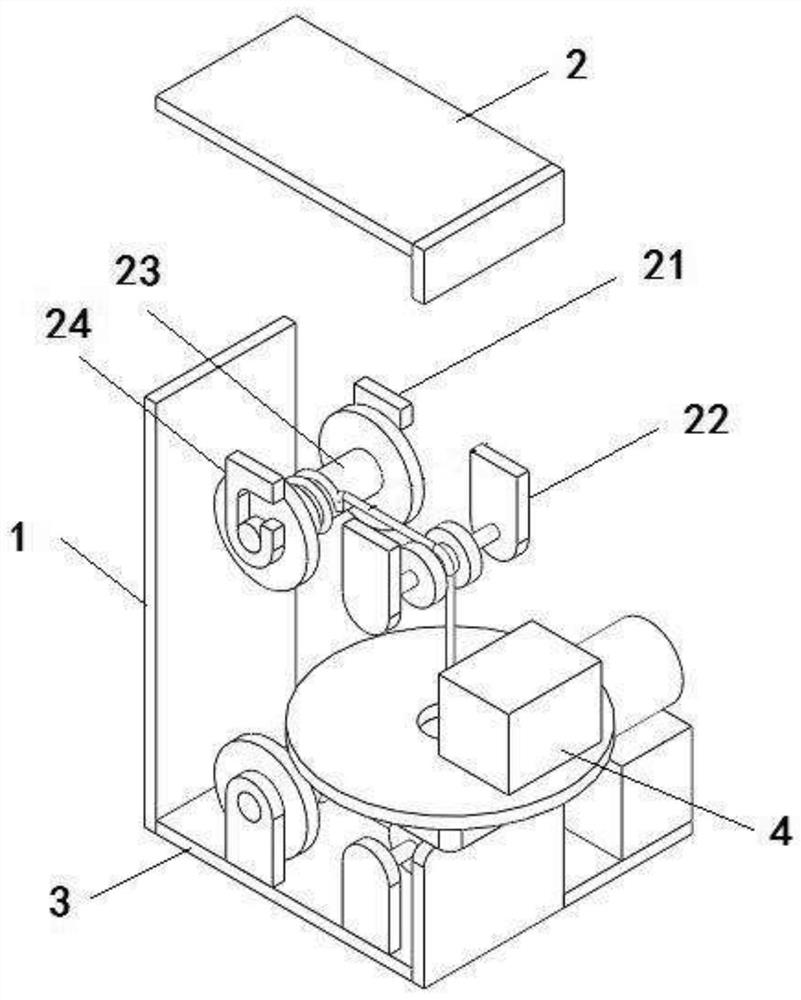

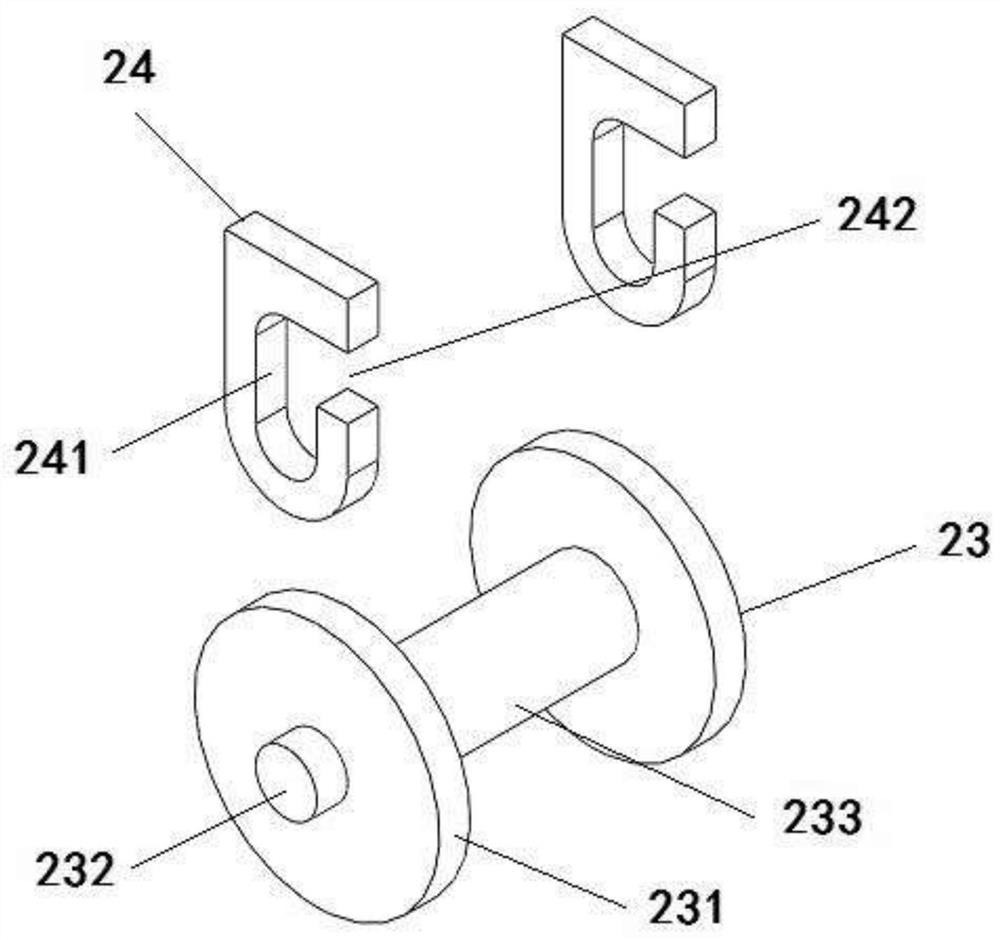

[0033] Such as figure 1 , figure 2 as shown, figure 1 It is a structural view of the novel cable surface defect detection device; figure 2 It is an exploded structural view of the novel cable surface defect detection device.

[0034] The new cable surface defect detection device of the present invention includes a fixed frame, a first winding assembly, a second winding assembly and a detection assembly 4, the first winding assembly, the second winding assembly, the detection assembly 4 are all arranged on the fixed frame, the detection assembly 4 is arranged between the first winding assembly and the second winding assembly, and the two ends of the cable to be tested are respectively arranged on the first winding assembly And on the second winding assembly, the detection assembly 4 detects the cable segment between the first winding assembly and the second winding assembly.

[0035] The fixing frame includes a vertical plate 1, a first mounting plate 2 and a second mount...

Embodiment 2

[0057] The detection method of the novel cable surface defect detection device of the present invention comprises the following steps:

[0058] S1, winding the cable to be tested to the outside of the first winding frame 23, and placing the first winding frame 23 in the first adjusting plate 24 after the winding is completed;

[0059] S2, pull one end of the cable to be tested, place the cable to be tested to pass through the guide cylinder 221 and the detection disc 41 in turn, use the detector 43 to record and detect, and start the second rotating motor 4124 , so that the detector 43 is rotated to detect the cable to be tested in all directions, the rotation speed of the detection disc 41 should be greater than the descending speed of the cable to be tested, so as to ensure that the detector 43 can perform full-surface rotation detection on the cable;

[0060] S3, continue to pull the cable to be tested, so that the cable to be tested passes through the rotating tube 411 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com