Multi-robot collaborative assembly line balancing method considering energy efficiency

A multi-robot, assembly line technology, applied in the instrument, energy industry, multi-objective optimization and other directions, can solve the problems of high cost and energy consumption of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0081] experiment

[0082] Based on the prioritization diagram of five classic problems (Jackson, Rosenberg, Gunther, Hahn, Tonge) proposed by previous research on assembly line balancing problems (http: / / www.assembly-line-balancing.de / ), random generation of robots Assemble the time and energy consumption of each task, and divide each problem into 4 different workstations, a total of 20 sets of data for experiments.

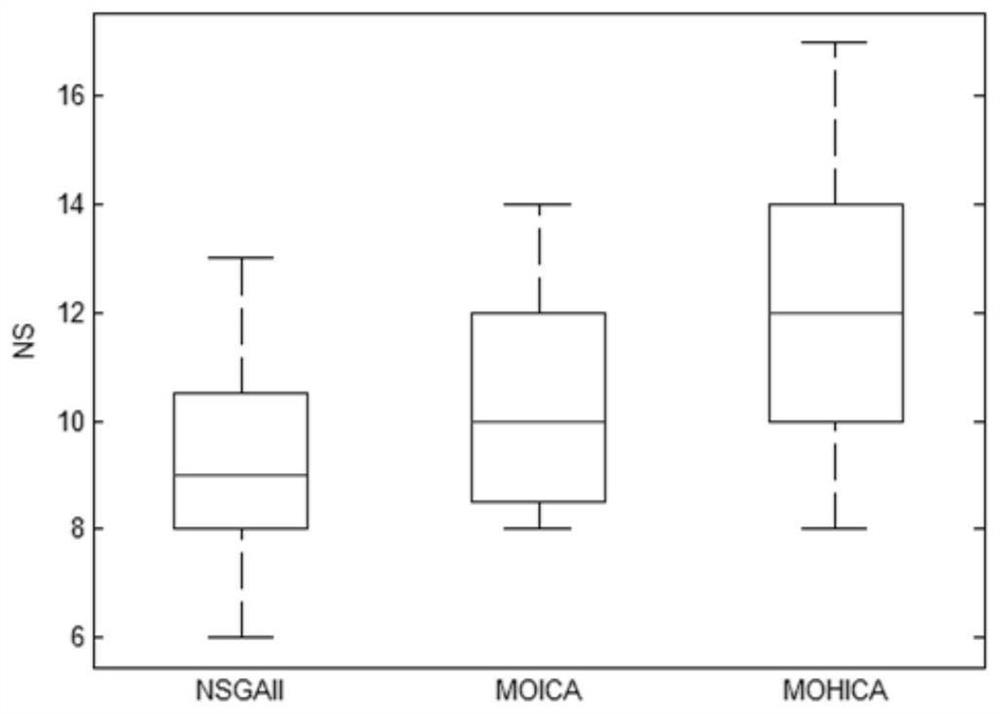

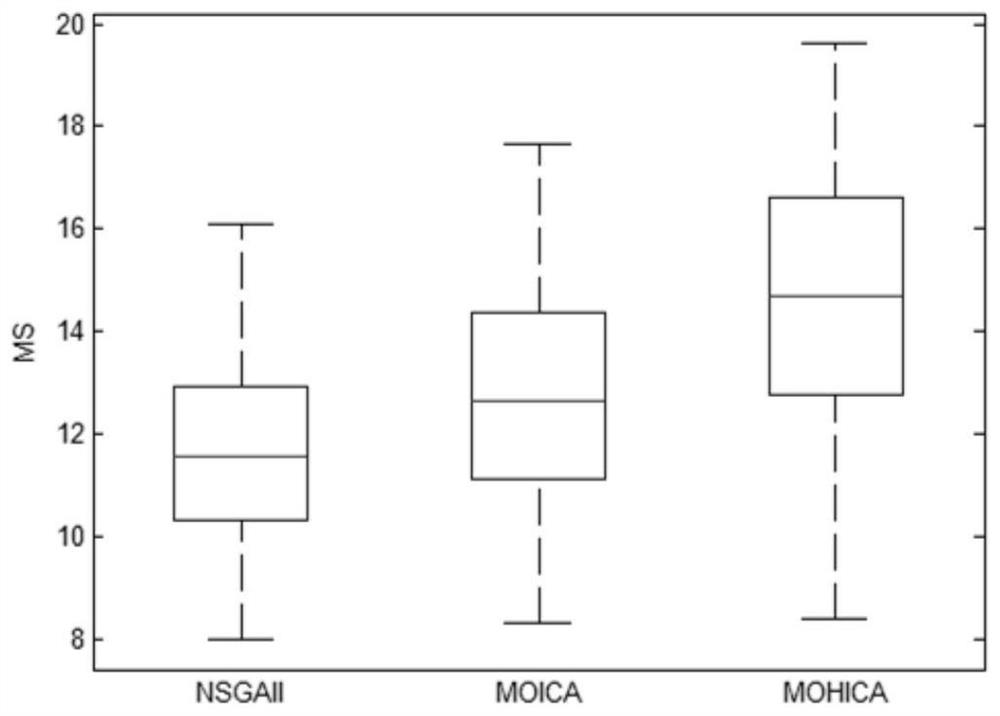

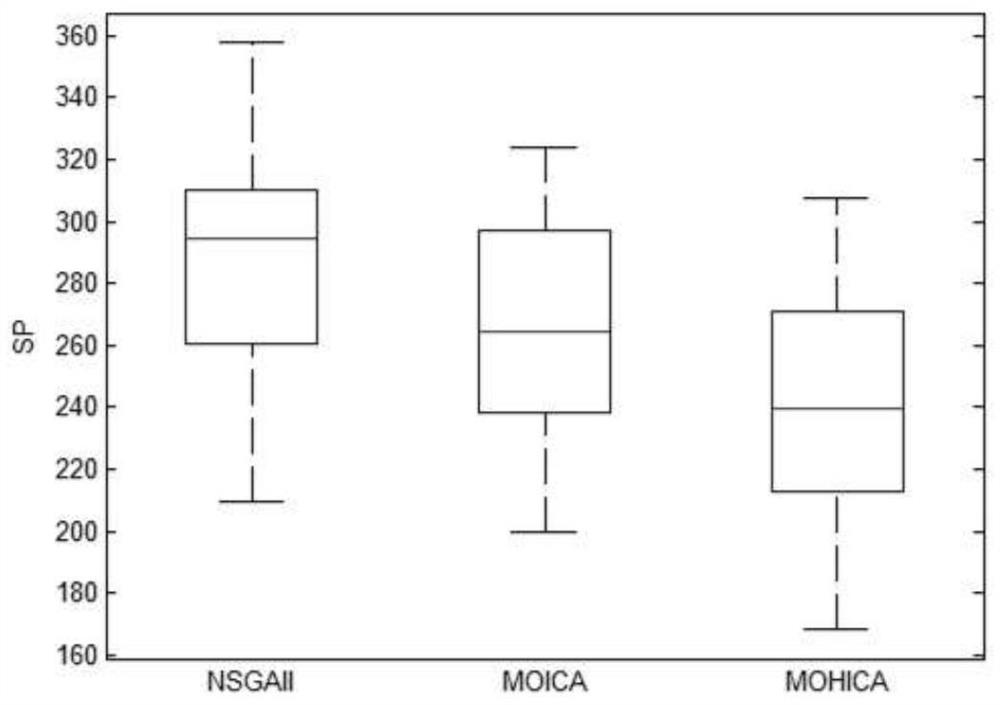

[0083] At the same time, the multi-objective imperialist competitive algorithm (MOHICA) proposed by the present invention is combined with the multi-objective imperialist competitive algorithm (Multi-Objective Imperialist Competitive Algorithm, MOICA) and the classical algorithm non-dominated selection that currently has better performance in solving multi-objective problems The genetic algorithm (NSGA-II) was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com