Bread composition with improved bread volume

A composition and bread technology, applied in baking mixture, dough cooling, food science, etc., can solve the problem of active ingredient loss, uneven distribution, etc., to achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

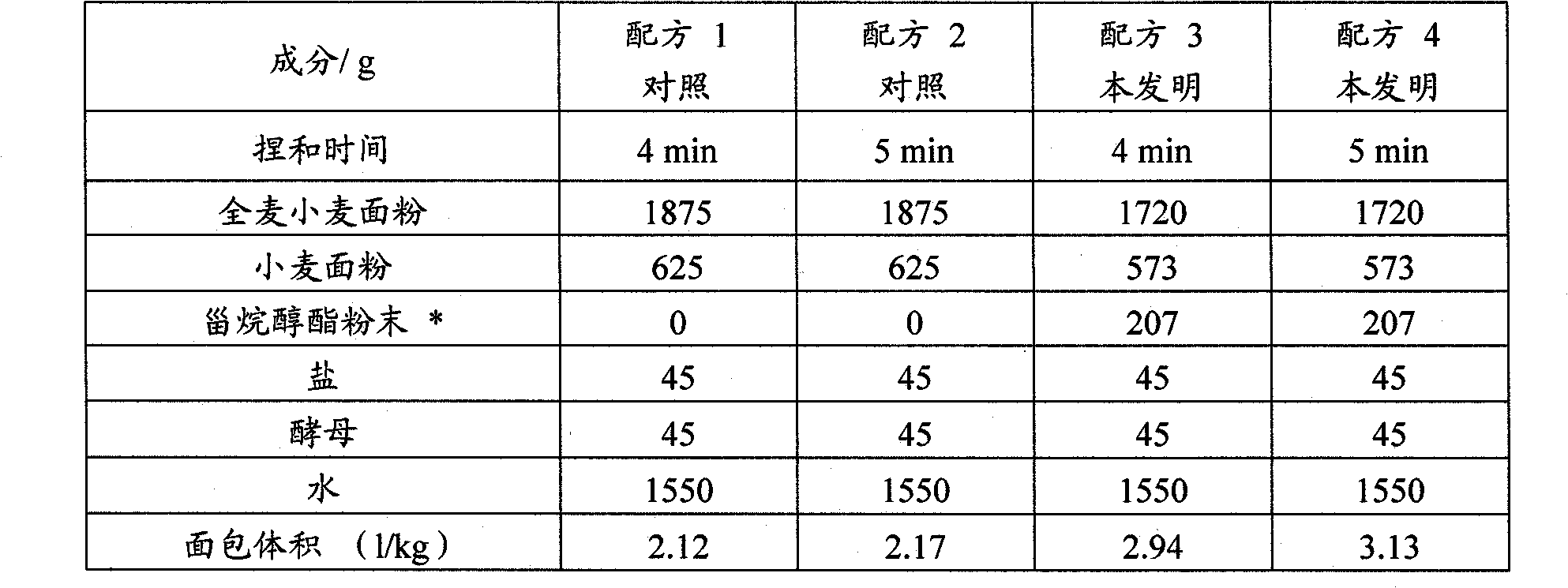

[0046] Effect of Kneading Time on Bread Volume

[0047] Whole wheat bread

[0048]

[0049] * Contains 70% phytostanol esters, 3% citric acid esters of mono- and diglycerides, 23% maltodextrin and 4% sodium caseinate.

[0050] The toast was made using procedures generally known in the art. Combine dry ingredients and add water and mix with dry ingredients. The dough is kneaded for 4 or 5 minutes, divided, risen (35 minutes), baked and cooled.

[0051] The dough is manually assessed by the baker. The dough made according to recipe 4 had as good a kneading stability as the shorter kneading dough (recipe 3). If the time was increased by one minute, the control dough lost kneading and stability. Longer kneading times improved the loaf volume of breads containing phytosterol esters and / or phytostanol esters in powder form (recipes 3 and 4). Kneading time had no real effect on the volume of the control breads (recipes 1 and 2).

[0052] Bread volume was determined by the ...

Embodiment 2

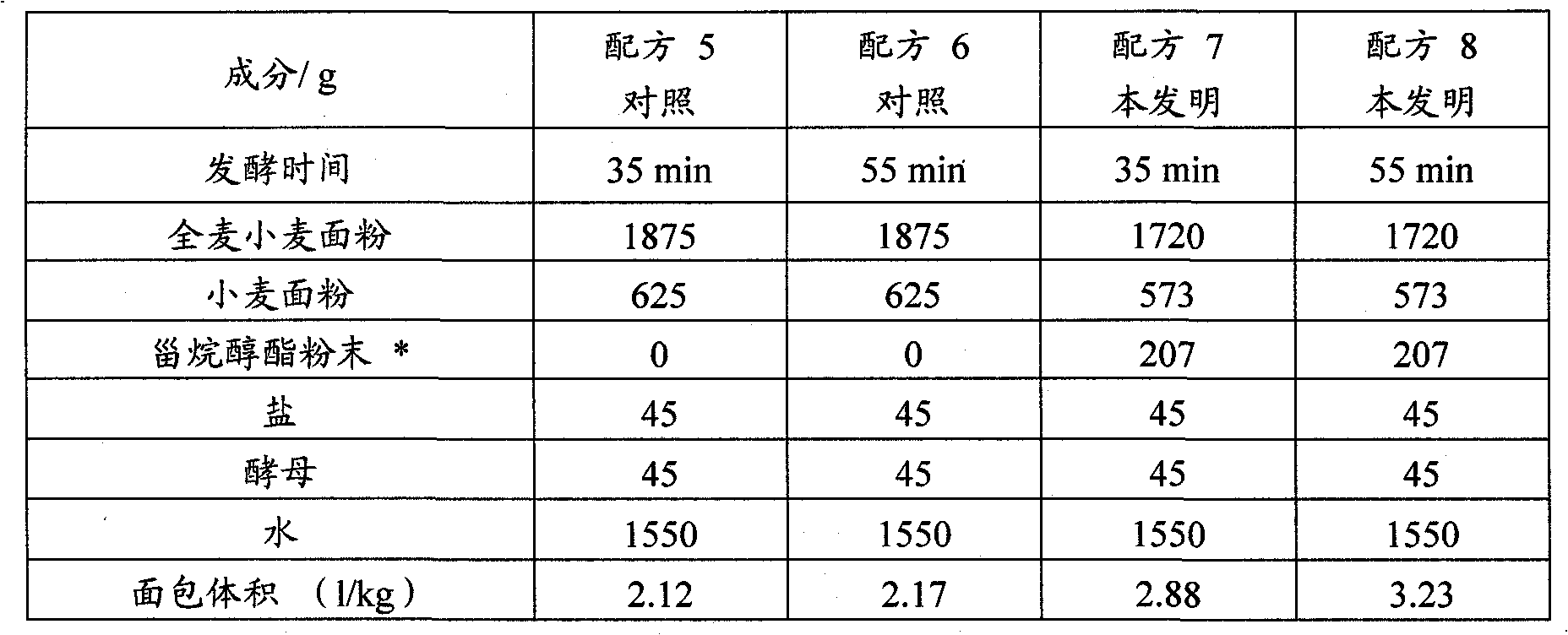

[0054] The Effect of Fermentation Time on Bread Volume

[0055] Whole wheat bread

[0056]

[0057] * Contains 70% phytostanol esters, 3% citric acid esters of mono- and diglycerides, 23% maltodextrin and 4% sodium caseinate.

[0058] The toast was made using procedures generally known in the art. Combine dry ingredients and add water and mix with dry ingredients. The dough is kneaded (4min), divided, fermented for 35 or 55 minutes, baked and cooled.

[0059] Doughs made with phytosterol esters and / or phytostanol esters in powder form (recipes 7 and 8) were stable over prolonged fermentation times. Bread volume was increased when longer fermentation times were used. The fermentation time had practically no positive effect on the volume of the control breads (recipes 5 and 6).

Embodiment 3

[0061] toast

[0062] Composition / g

Recipe 1

Recipe 2

Recipe 3

Recipe 4

control

baking fat

free sterols

this invention

2500

2361

2417

2295.5

baking fat *

0

139

0

0

free sterol **

0

0

83

0

Stanol Esters Powder ***

0

0

0

204.5

Salt

45

45

45

45

45

45

45

45

water

1500

1500

1500

1500

Bread volume (l / kg)

3.39

3.66

3.52

3.98

[0063] * Includes partially hydrogenated canola oil (which contains trans fatty acids), palm oil, and canola oil. The amount of fat in the baking fat was comparable to the fat content (ie, the fatty acid from the fatty acid portion of the stanol ester) of the stanol ester powder in recipe 4.

[0064] ** The amount of stanol ester powder and free sterol used had an equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com