Fireproof coating material for plastics

A technology for fire-retardant coatings and plastics, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of non-filming of coatings, low thermal deformation temperature of plastics, and limited heating temperature, so as to overcome the lack of durability and improve The effect of flame retardant performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

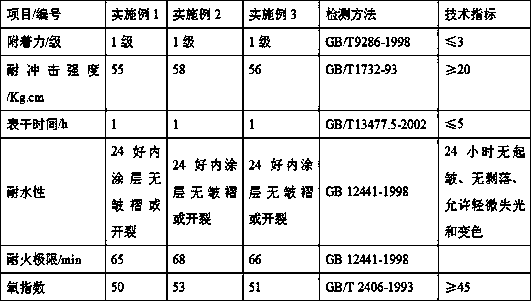

Embodiment 1

[0022] A fireproof coating for plastics is prepared from the following raw materials in parts by weight.

[0023] 25 parts of epoxy emulsion, 19 parts of high chlorinated polyethylene resin (0.8-0.9 μm in particle size), 21 parts of ammonium polyphosphate (0.8-0.9 μm in particle size), 10 parts of pentaerythritol (0.8-0.9 μm in particle size), hair Foam agent sepiolite (0.8-0.9μm particle size) 15 parts, melamine (0.8-0.9μm particle size) 6 parts, organic curing agent triethanolamine 2 parts, pigment iron red (0.8-0.9μm particle size) / 15 1 part, pigment and filler titanium dioxide (0.8-0.9 μm particle size) 14 parts, defoamer polyether defoamer 1 part and coupling agent titanate 1 part.

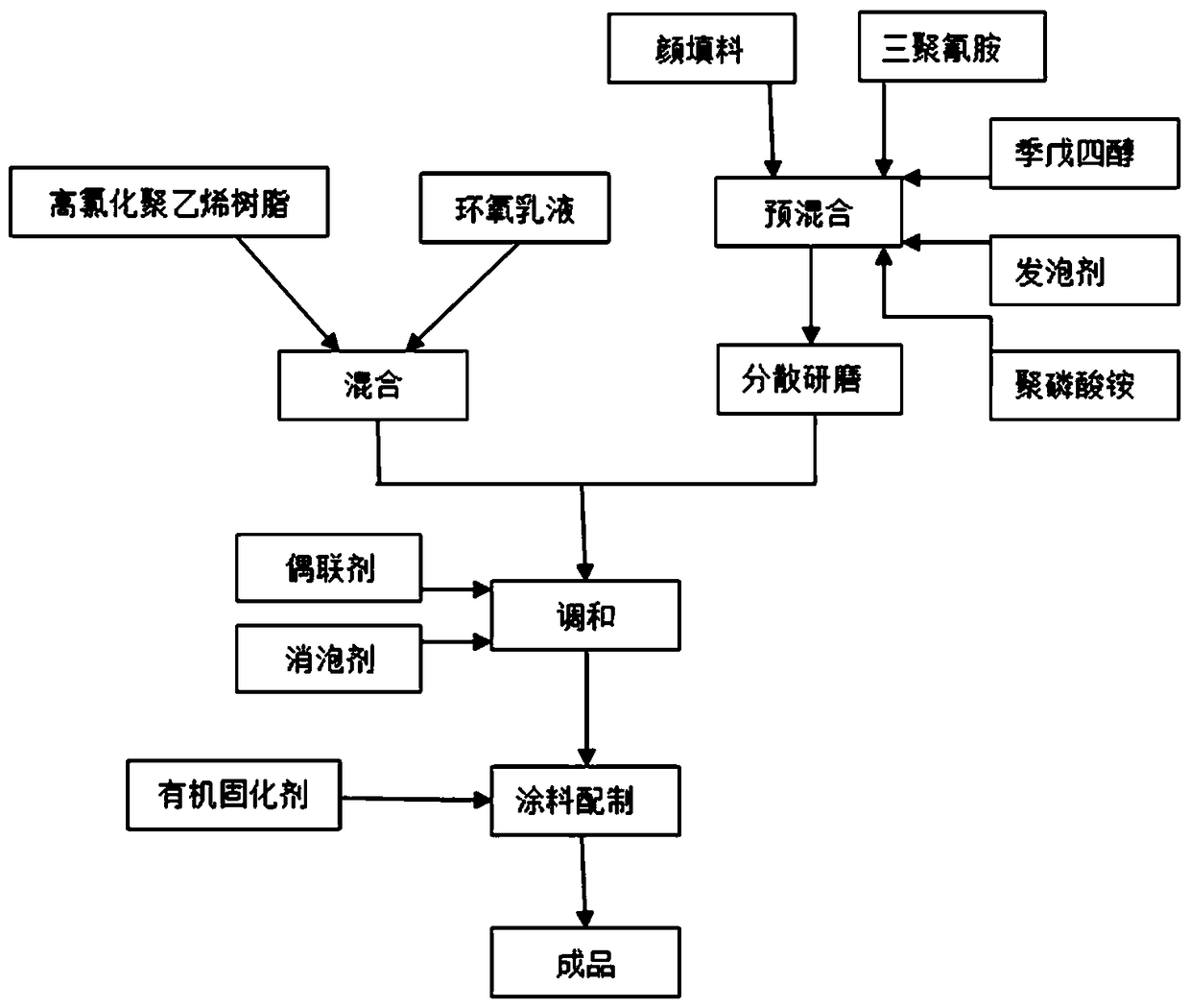

[0024] The preparation steps are as follows.

[0025] (1) Grinding: Weigh and pre-mix pigments and fillers, melamine, pentaerythritol, foaming agent and ammonium polyphosphate according to parts by weight, put them into a three-roll mill for grinding, the distance between the rolls is 3, and...

Embodiment 2

[0028] A fireproof coating for plastics is prepared from the following raw materials in parts by weight.

[0029] 30 parts of epoxy emulsion, 15 parts of high chlorinated polyethylene resin (0.8-0.9 μm in particle size), 25 parts of ammonium polyphosphate (0.8-0.9 μm in particle size), 12 parts of pentaerythritol (0.8-0.9 μm in particle size), hair Foam agent expandable graphite (0.8-0.9μm particle size) 12 parts, melamine (0.8-0.9μm particle size) 8 parts, organic curing agent triethanolamine 2 parts, pigment and filler iron yellow (0.8-0.9μm particle size) 10 parts And 15 parts of iron red (particle size: 0.8-0.9 μm) for pigment and filler, 1 part of water-based defoamer for defoaming agent and 1 part of coupling agent titanate.

[0030] The preparation steps are as follows.

[0031] (1) Grinding: Weigh and pre-mix pigments and fillers, melamine, pentaerythritol, foaming agent and ammonium polyphosphate according to parts by weight, put them into a three-roll mill for grind...

Embodiment 3

[0034] A fireproof coating for plastics is prepared from the following raw materials in parts by weight.

[0035] 28 parts of epoxy emulsion, 10 parts of high chlorinated polyethylene resin (0.8-0.9 μm in particle size), 29 parts of ammonium polyphosphate (0.8-0.9 μm in particle size), 15 parts of pentaerythritol (0.8-0.9 μm in particle size), hair Foaming agent sepiolite (0.8-0.9μm in particle size) 5 parts, foaming agent expandable graphite (0.8-0.9μm in particle size) 5 parts, melamine (0.8-0.9μm in particle size) 9 parts, organic curing agent methyl 2 parts of silicone oil, 20 parts of pigment and filler titanium dioxide (particle size 0.8-0.9 μm), 1 part of defoamer polyether defoamer and 1 part of coupling agent titanate.

[0036] The preparation steps are as follows.

[0037] (1) Grinding: Weigh and pre-mix pigments and fillers, melamine, pentaerythritol, foaming agent and ammonium polyphosphate according to parts by weight, put them into a three-roll mill for grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com