Apparatus for cross-sectionally shaping a multiplicity of plastics fibre bundles guided in parallel

A technology of cross-section and equipment, applied in the field of equipment for cross-section forming of plastic fiber bundles, can solve the problems of time-consuming, replacement and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

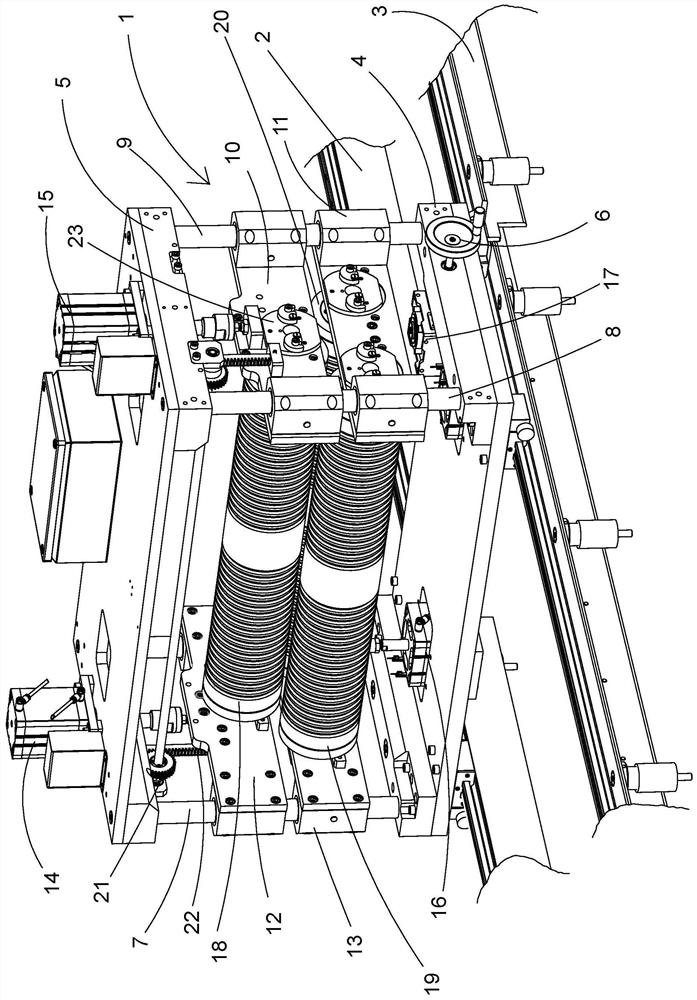

[0024] figure 1 The apparatus shown in includes a frame 1 basically formed by a pair of upper axle carriers 5 and a pair of lower axle carriers 4 , which are interconnected by four vertical guide bars 7 , 8 , 9 . The frame 1 can be moved in a horizontal plane by means of a hand wheel 6 on a rail assembly having two parallel rails 2 and 3 .

[0025] A pair of upper guide plates 10 , 12 and a pair of lower guide plates 11 , 13 are vertically movable on the guide rods 7 , 8 , 9 . The pair of guide plates 10 , 12 can be raised or lowered by hydraulic lifting devices 14 , 15 . Correspondingly, the pair of lower guide plates 11 , 13 can be raised or lowered by the lower lifting devices 16 , 17 .

[0026] In order to ensure the synchronization of said raising and lowering, the pair of guide plates is assigned a pair of gears 21 interconnected by connecting rods, said gears meshing into a pair of toothed rods 22 on either side of the device and thus allowing the parallelism of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com