Multi-adaptive blade feeding rotary table applied to blade precision forging automatic production line

An automatic production line and precision forging technology, which is applied in the direction of manufacturing tools, engine components, forging/pressing/hammer devices, etc., can solve problems that affect production efficiency, tooling fixtures occupy a large amount of time, and batches are small in variety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Aiming at the characteristics of relatively small batches and relatively many types of precision forging vane production lines, the present invention increases the flexibility of the device as much as possible to minimize the switching time of tooling and fixtures when switching products, and at the same time meets the requirements of automatic production for positioning accuracy and ensures that robots Accuracy and stability of gripping.

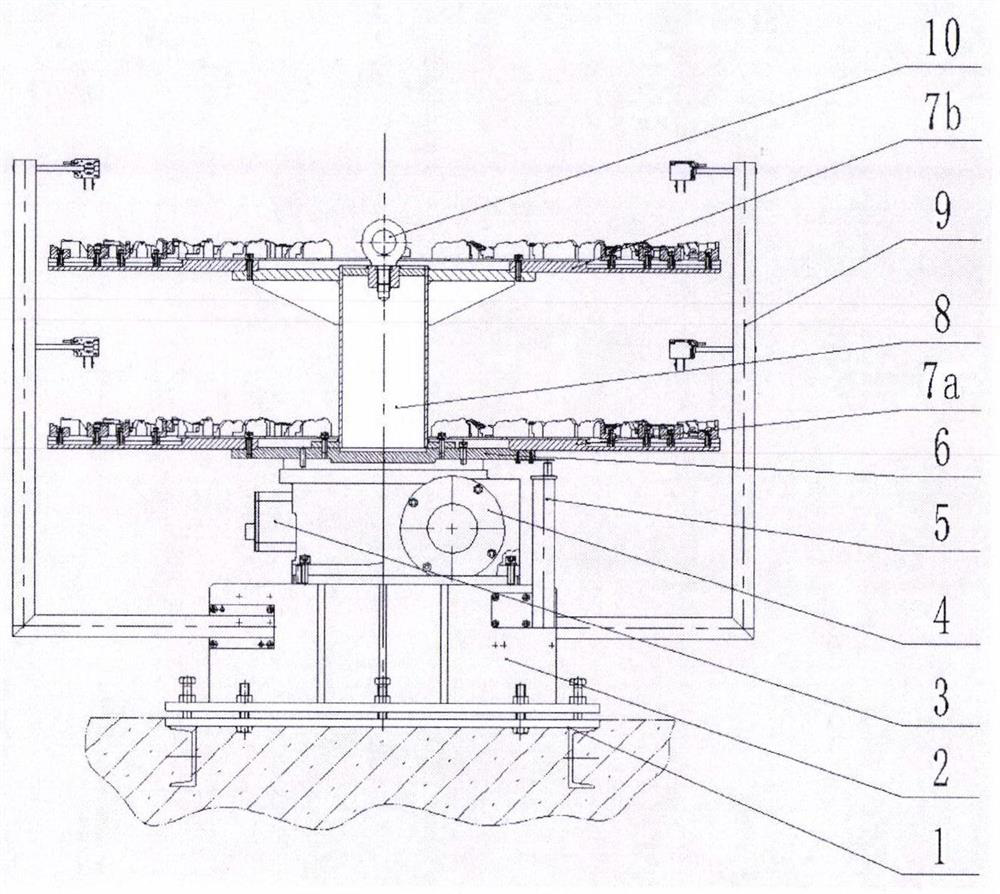

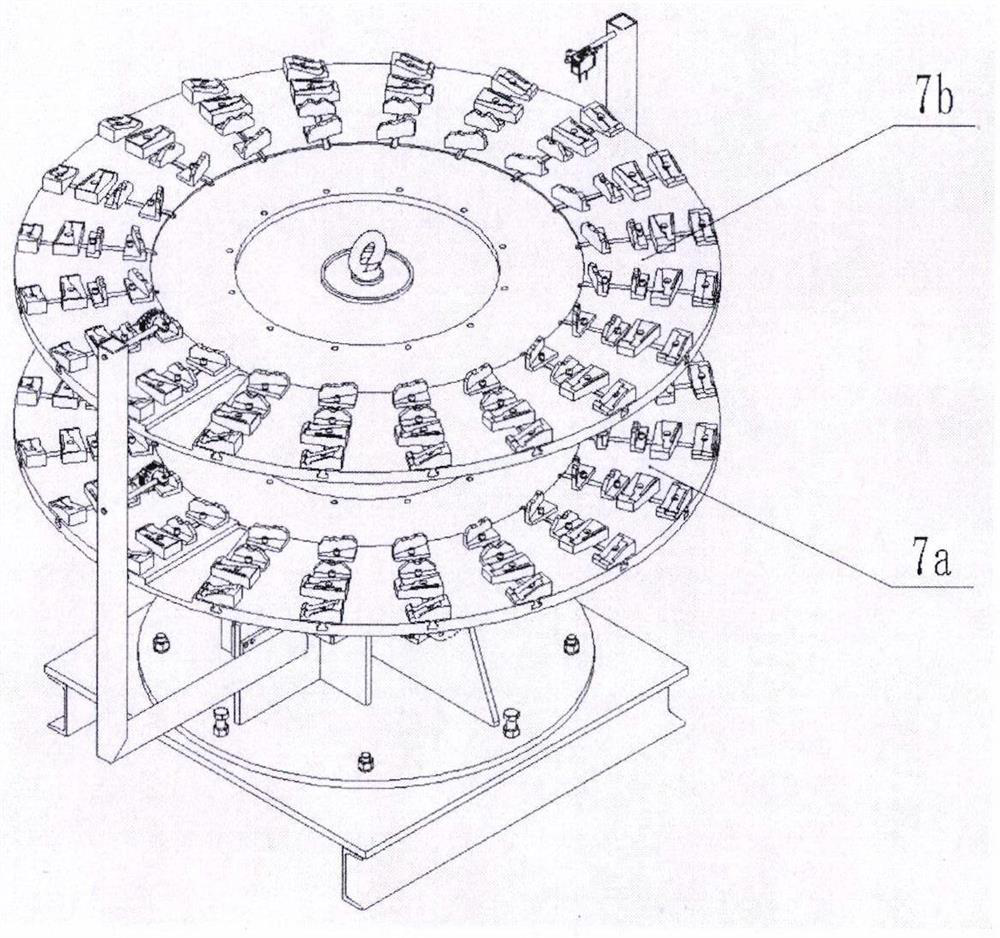

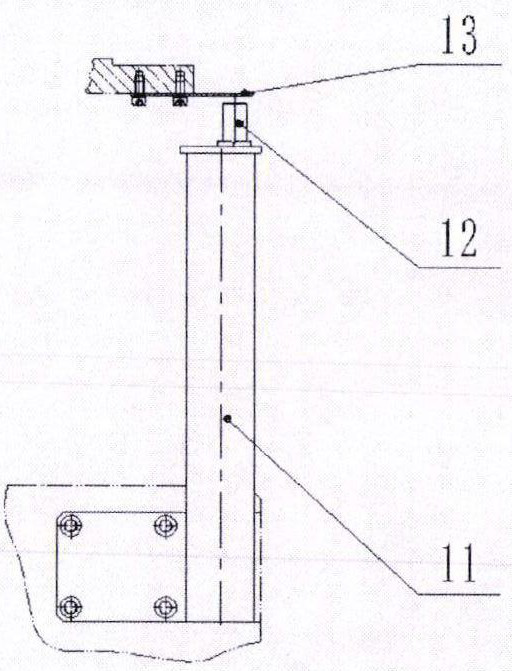

[0014] figure 1 In the middle is the general drawing of the multi-adaptive blade feeding turntable. The base (2) is fixed on the foundation (1) through the compression screw and the jacking screw. By adjusting the compression screw and the jacking screw, the level of the entire feeding turntable can be adjusted; The degree table (4), the zero-clearing proximity switch assembly (5), and the material-free detection assembly (9) are installed on the base (2) through screws; the transitional mounting plate (6) is installed on the indexin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com