Four-corner drilling machine suitable for equilateral drilling treatment

A four-corner, drilling machine technology, used in drilling/drilling equipment, boring/drilling, boring machine/drilling machine components, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

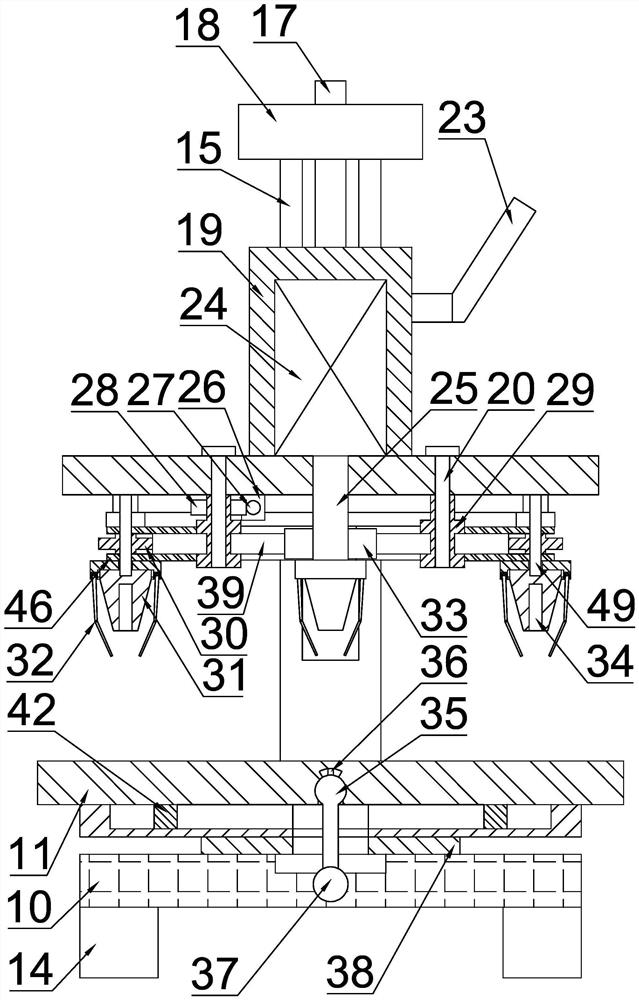

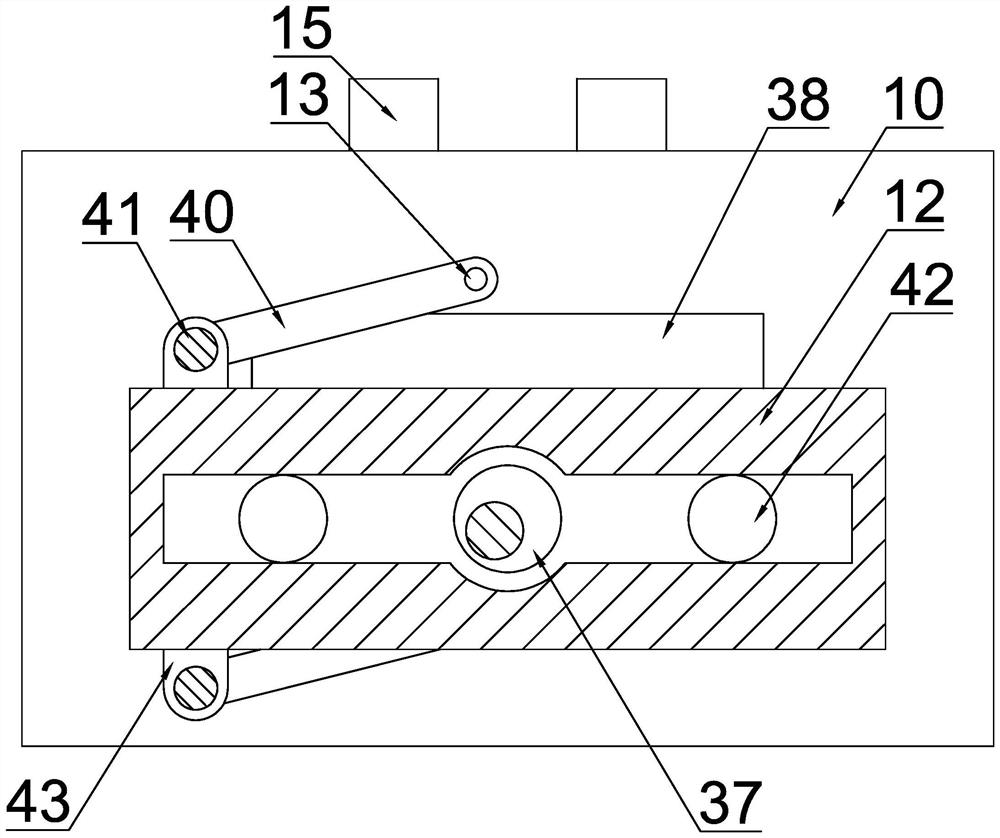

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

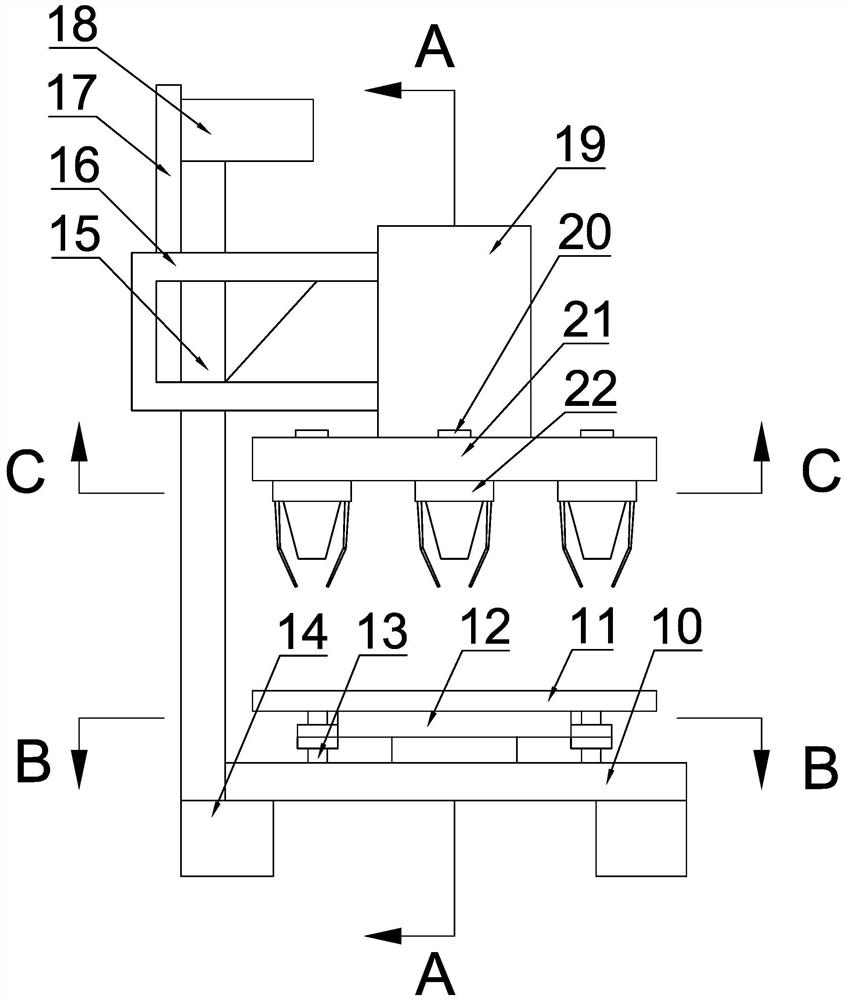

[0026] like figure 1 As shown, a four-corner drilling machine suitable for equilateral drilling processing includes a housing 10, four support blocks 14 are fixed and symmetrical at the lower end of the housing 10, and a support plate 15 is fixed on the left side of the housing 10. The support plate 15 A manual lifting device is provided on the top, and the manual lifting device is used for manually lifting the drilling equipment. The upper end of the housing 10 is fixed with a manual adjustment drilling platform device, and the manual adjustment drilling platform device is used to adjust the relative position of the drilling platform and the drill bit.

[0027] like figure 1 , figure 2 and Figure 4 As shown, the manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com