Yinqiao powder tablet production device

A production device, technology of Yinqiaosan, which is applied in the field of Yinqiaosan tablet production device, can solve the problems that the particle size cannot be further processed and the raw material requirements are too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

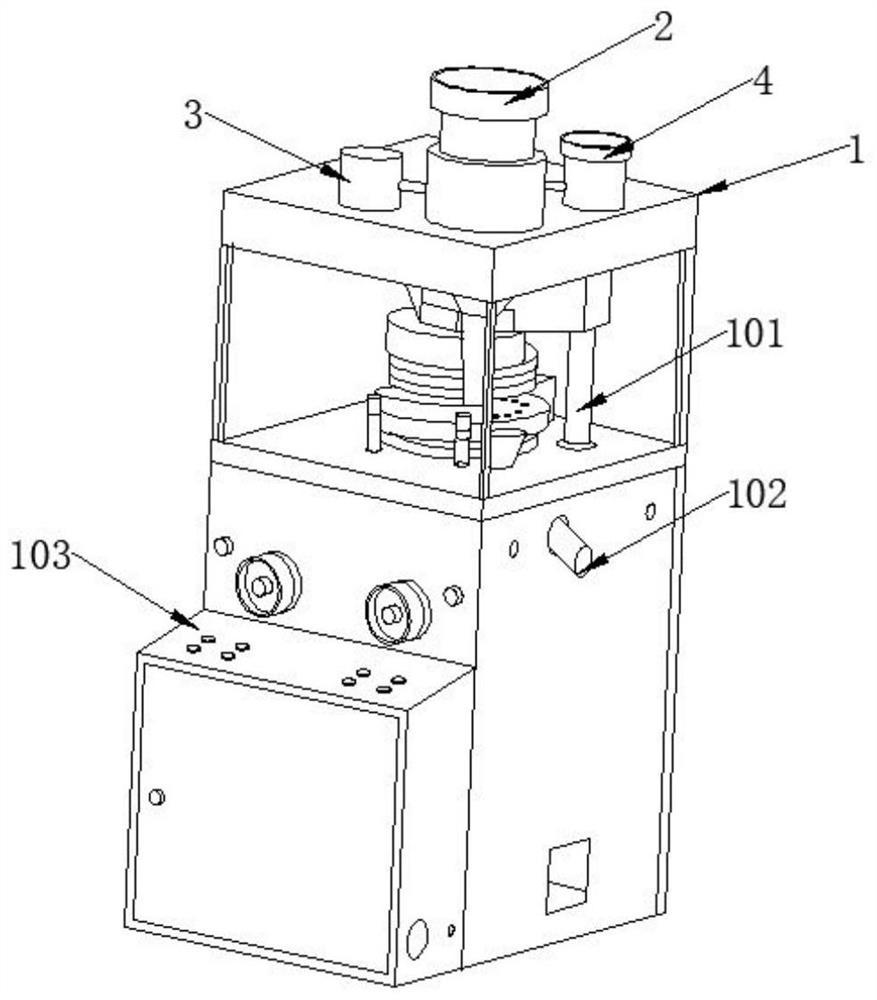

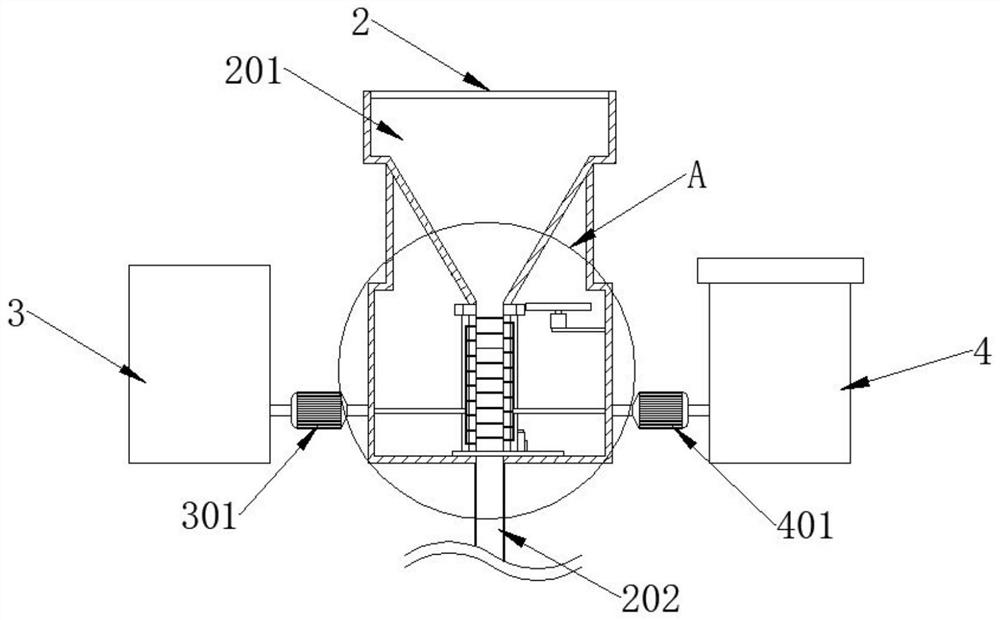

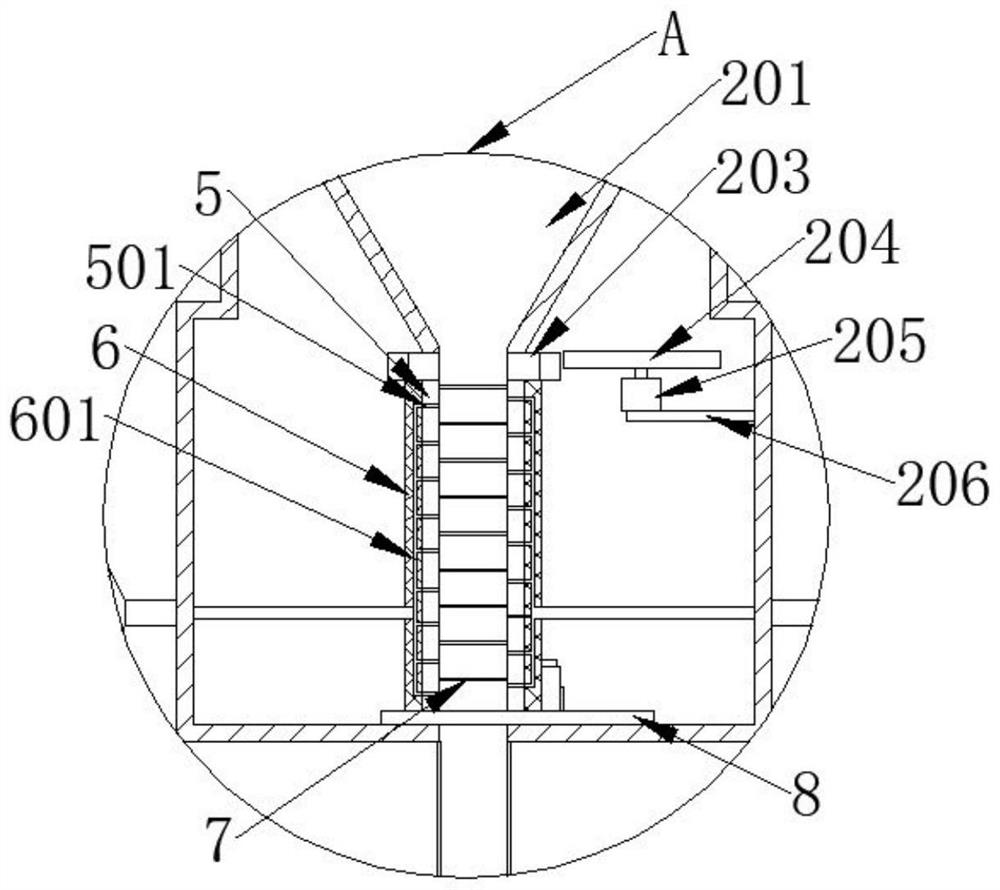

[0028] Such as Figure 1-6 As shown, the present invention provides a Yinqiao powder tablet production device, including a device main body 1, the device main body 1 includes a drug pressing mechanism 101, a drug outlet 102, a control panel 103 and a drug feeding structure 2, the drug feeding structure 2 A water storage tank 3 is installed on one side, and a glue storage box 4 is installed on the other side of the medicinal structure 2, and the medicinal structure 2 is connected with the water storage box 3 and the glue storage box 4 respectively, and the glue storage box 4 includes a first motor 401, the water storage tank 3 includes a second motor 301, a funnel mouth 201 is provided at the top of the medicine feeding structure 2, a medicine feeding pipeline 202 is installed at the bottom of the medicine feeding structure 2, and a bearing 203 is installed at the bottom of the funnel mouth 201 A transmission gear 204 is installed on one end of the bearing 203, a third motor 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com