Energy-saving, efficient and low-noise press hydraulic system

A technology of hydraulic system and low noise, applied in the field of hydraulic system of presses, can solve the problems of low system efficiency, high noise and high cost, and achieve the effects of high system efficiency, low noise and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

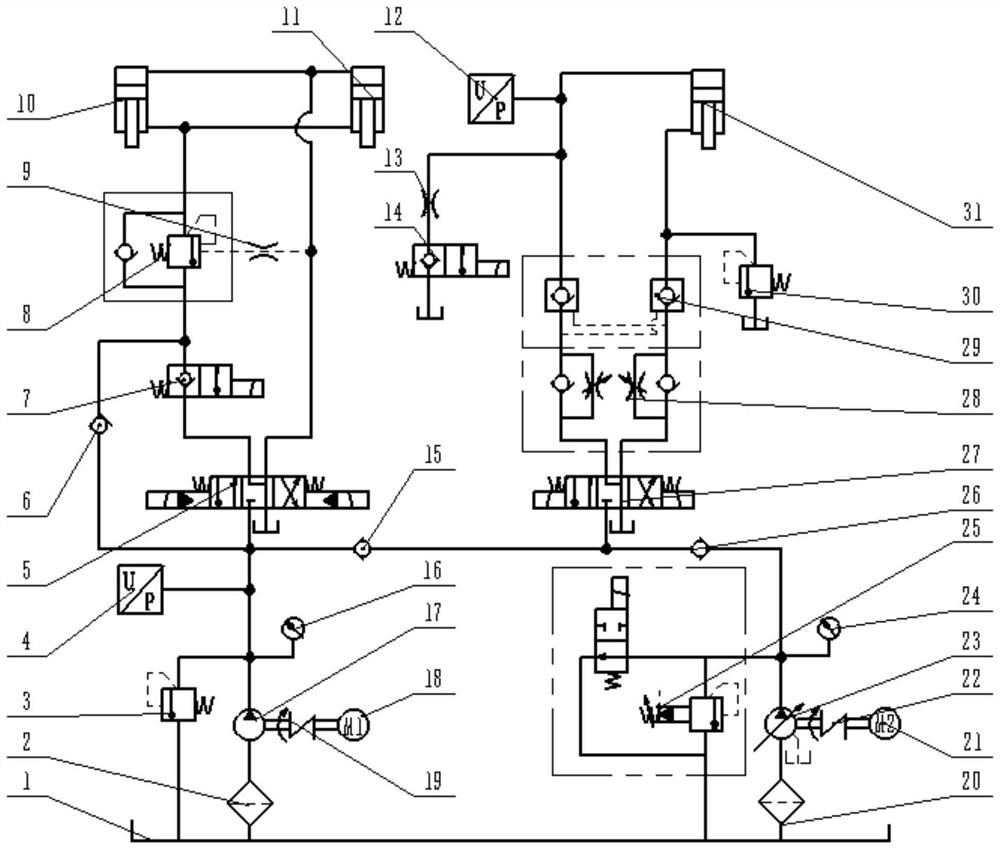

[0021] The embodiments of the present invention will be further described below with reference to the drawings:

[0022] Hydraulic system for energy saving and low noise press, such as figure 1 As shown, the fuel tank 1; the first oil oil filter 2; the first straight-moving relief valve 3; the first pressure sensor 4; three four-flow electric hydraulic replace valve 5; first single-way valve 6; One or two two-way electromagnetic ball valve 7; external control one-way balancing valve 8; first anchor hole 9; movable plate driving long stroke hydraulic cylinder 10; movable plate driving hydraulic cylinder 11; second pressure sensor 12; second throttle Hole 13; second two-stage two-way electromagnetic ball valve 14; second single-way valve 15; first pressure table 16; internal meshing gear pump 17; AC servo motor 18; first coupling 19; second oil oil filter 20; three-phase asynchronous motor 21; second coupling 22; constant voltage variable plunger pump 23; second pressure table 24; e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com