Low-flow-resistance mute air distributor

A technology of air distributor and low flow resistance, which is applied in the field of cabin air distributor, which can solve problems affecting the daily work and life of cabin personnel, uneven wind impact diffuser, instability, etc., to reduce the effect of sound transmission and wind flow The effect of increased stability and smooth flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

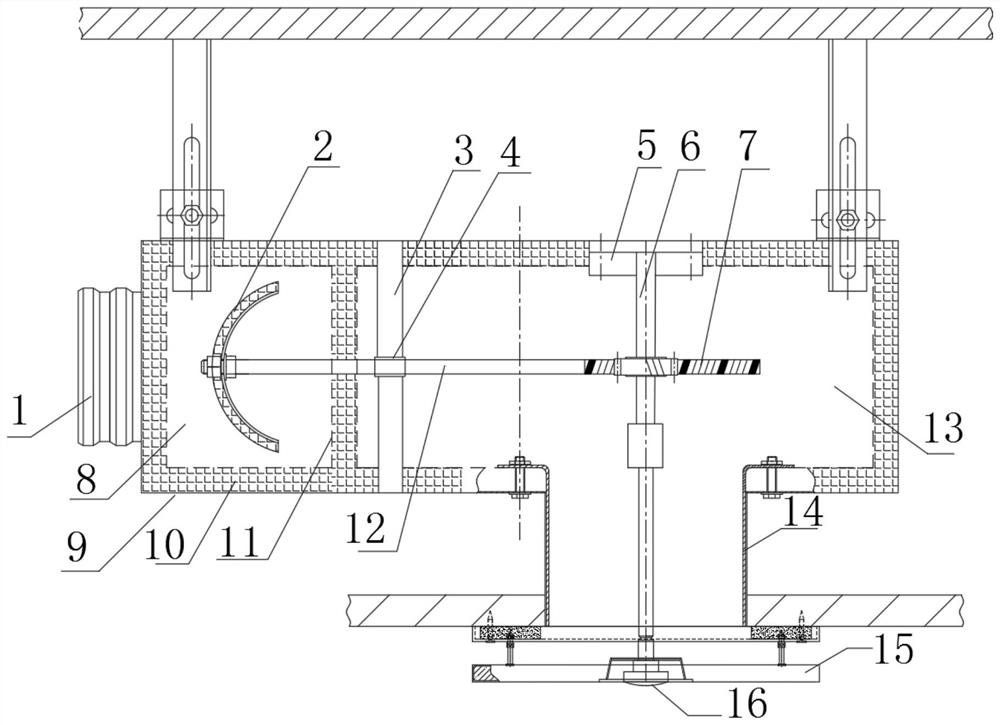

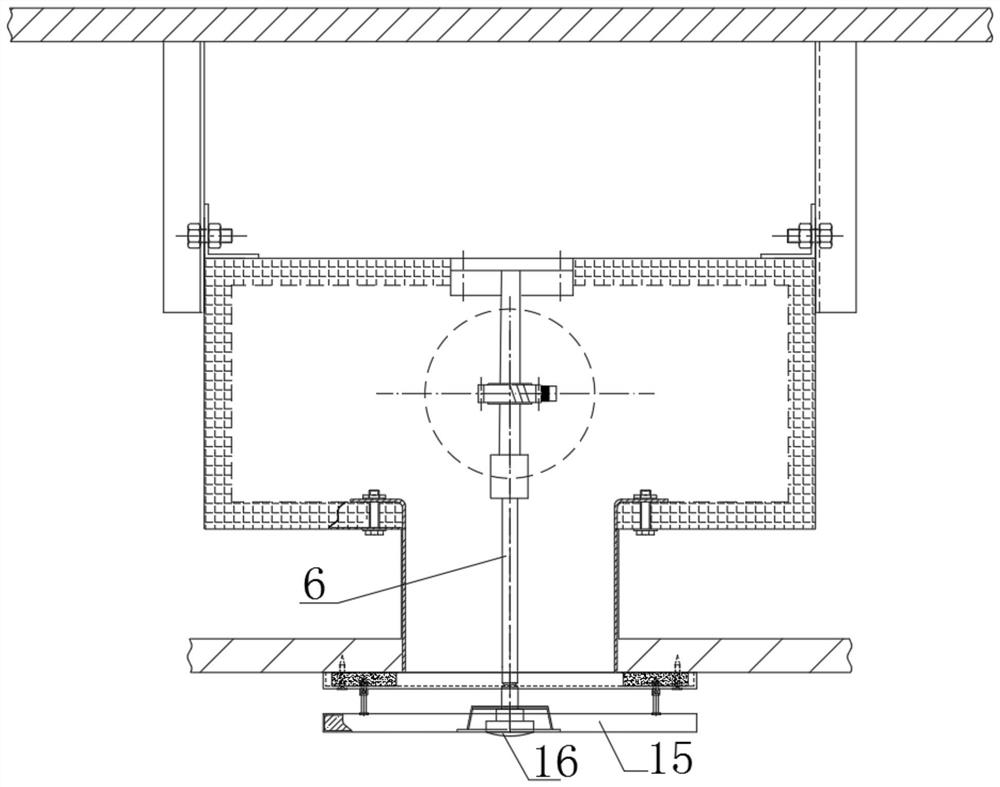

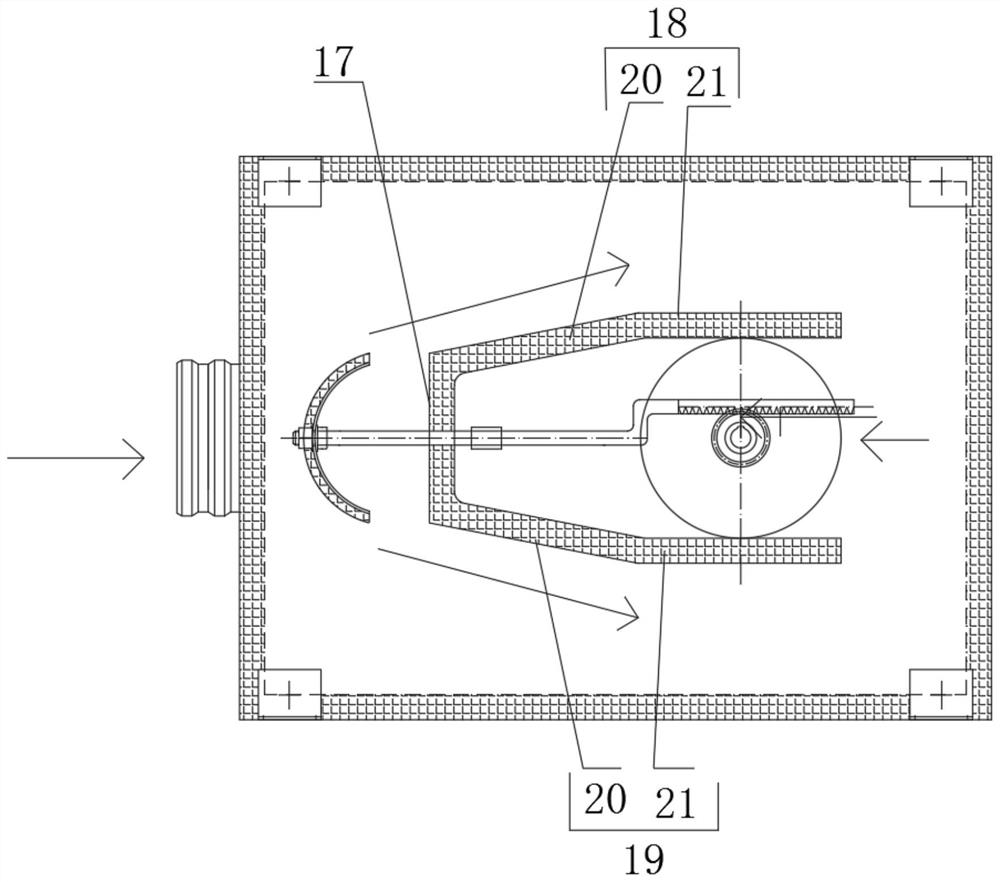

[0029] The specific implementation manner of the present technology is further described below according to the accompanying drawings:

[0030] Such as Figure 1 to Figure 3 As shown, a low-resistance silent air distributor includes a static pressure box 9, a spherical air volume adjustment mechanism and a conical deflector 11. The front side of the plenum 9 is provided with an air inlet, and the bottom is provided with a circular air outlet, and a spherical air volume adjustment mechanism and a conical deflector 11 are arranged inside.

[0031] The conical baffle 11 is located in the middle of the plenum 9, the top of the conical baffle 11 is connected to the top of the plenum 9 by bolts or welding, and the bottom is connected to the static plenum by bolts or welding. bottom of box 9.

[0032] The spherical air volume adjustment mechanism includes a spherical baffle 2, a transverse rack adjustment rod 12 and a vertical gear adjustment rod 6, the spherical baffle 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com