Outer sound insulation type gas turbine switching segment air inlet channel of corrugated plate structure

A technology for air intake channels and gas turbines, applied in gas turbine devices, jet propulsion devices, mechanical equipment, etc., can solve problems affecting performance, inconvenient maintenance, flying out, etc., to improve stability and safety, and facilitate disassembly and reinstallation Effect of installation and reduction of reproduction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

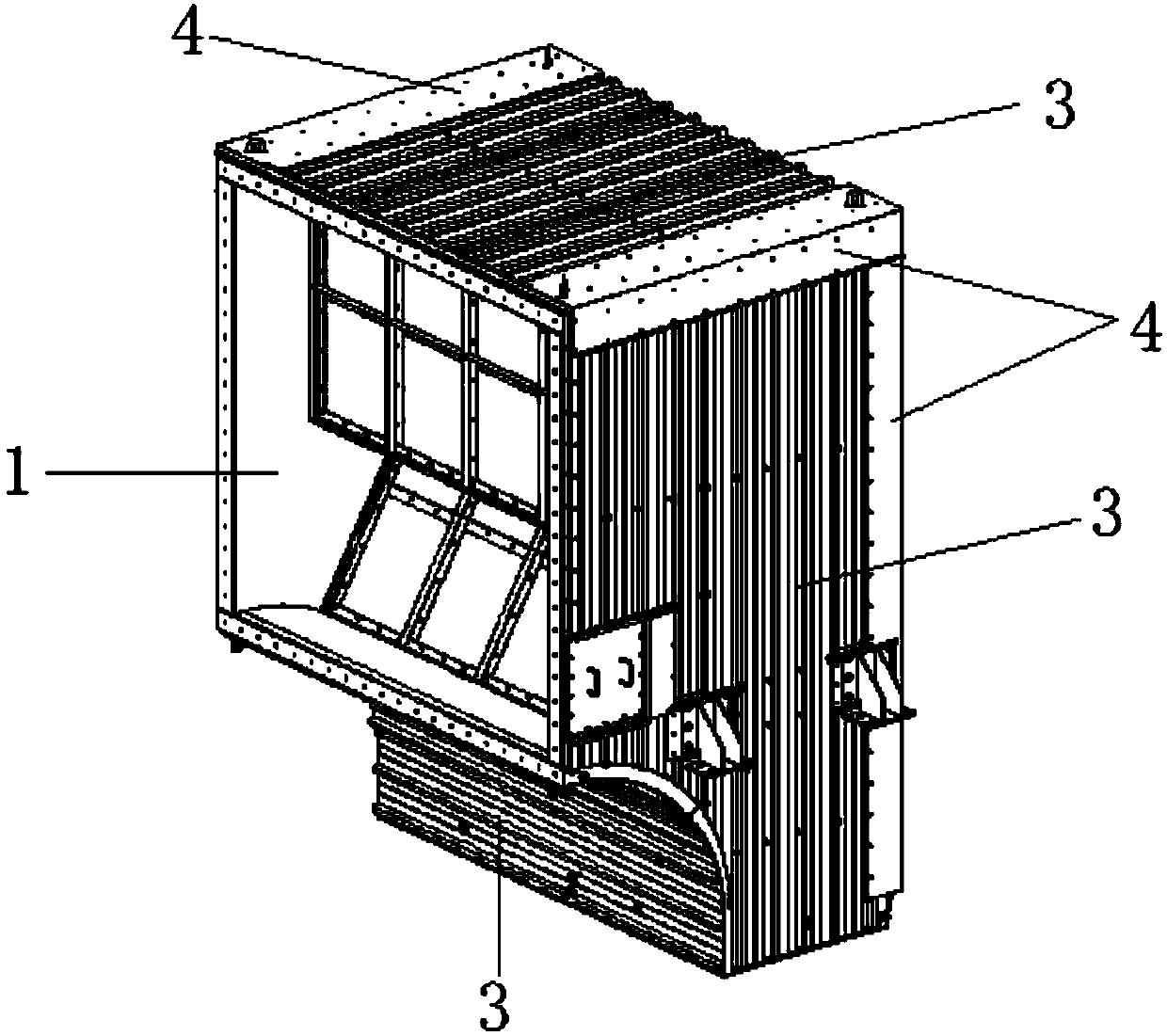

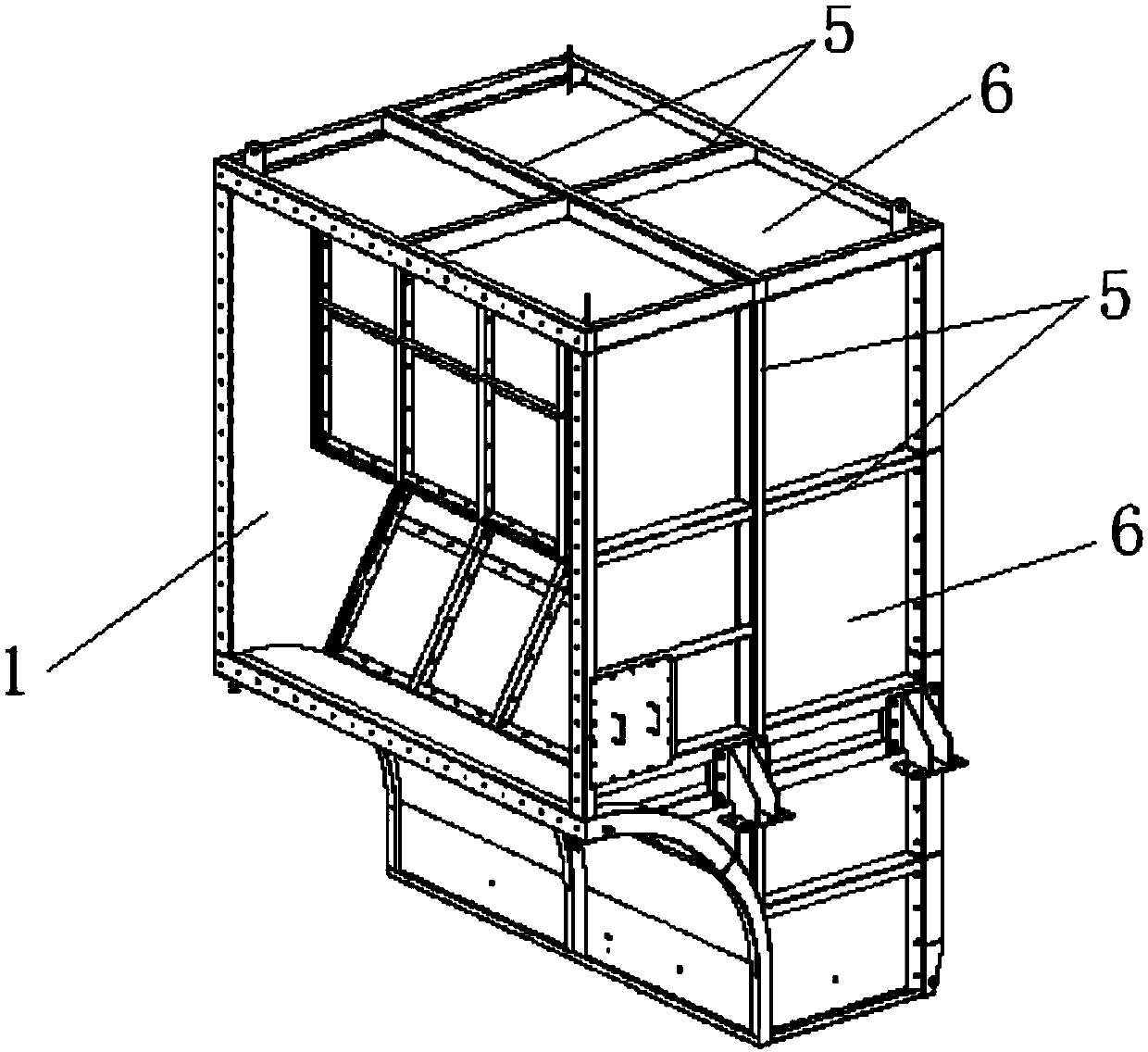

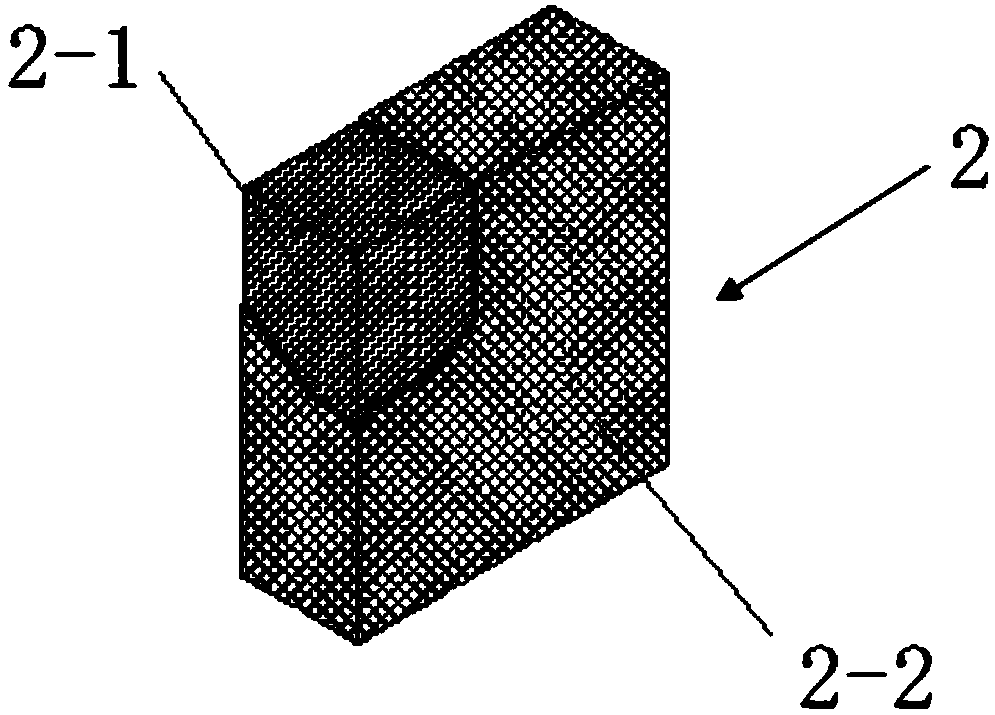

[0035] In this embodiment, the schematic diagram of the structure of the intake channel of the transition section of the external sound-proof gas turbine with corrugated plate structure is as follows figure 1 As shown, it includes the intake channel body 1 of the transition section, the soundproof cotton block 2, and the corrugated plate 3. Schematic diagram of the structure of the inlet channel body of the transfer section as shown in figure 2 As shown, the intake passage body 1 of the transfer section is a large sheet metal box structure with a vertical transfer shape formed by welding stainless steel plates and an impurity filter inside. Ribs 5 are provided, and the ribs divide the outer surface of the intake passage body of the transition section into several empty areas 6 . The structural diagram of the soundproof cotton block 2 is as follows: image 3As shown, the soundproof cotton block 2 is composed of an inner core 2-1 and a glass fiber cloth layer 2-2 wrapped on t...

Embodiment 2

[0037] In this embodiment, the schematic diagram of the structure of the intake channel of the transition section of the external sound-proof gas turbine with corrugated plate structure is as follows figure 1 As shown, it includes the intake channel body 1 of the transition section, the soundproof cotton block 2, and the corrugated plate 3. Schematic diagram of the structure of the inlet channel body of the transfer section as shown in figure 2 As shown, the intake passage body 1 of the transfer section is a large sheet metal box structure with a vertical transfer shape formed by welding stainless steel plates and an impurity filter inside. Ribs 5 are provided, and the ribs divide the outer surface of the intake passage body of the transition section into several empty areas 6 . The structural diagram of the soundproof cotton block 2 is as follows: image 3 As shown, the soundproof cotton block 2 is composed of an inner core 2-1 and a glass fiber cloth layer 2-2 wrapped on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com