Double-wall hollow pier column top support connecting joint and construction method

A technology for connecting nodes and hollow piers, applied in construction, bridge construction, bridge parts, etc., can solve problems such as restricting the application of composite pipe-concrete-steel double-walled hollow piers, avoid adverse effects, facilitate construction, construction handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

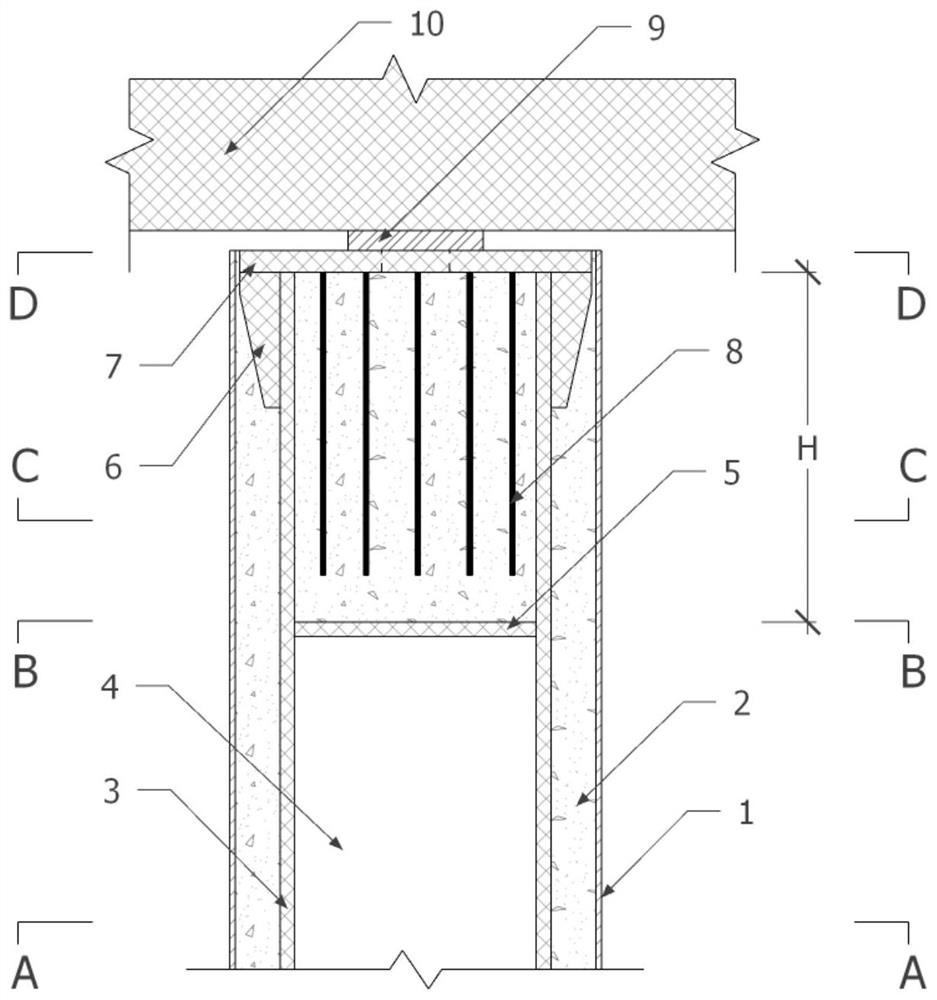

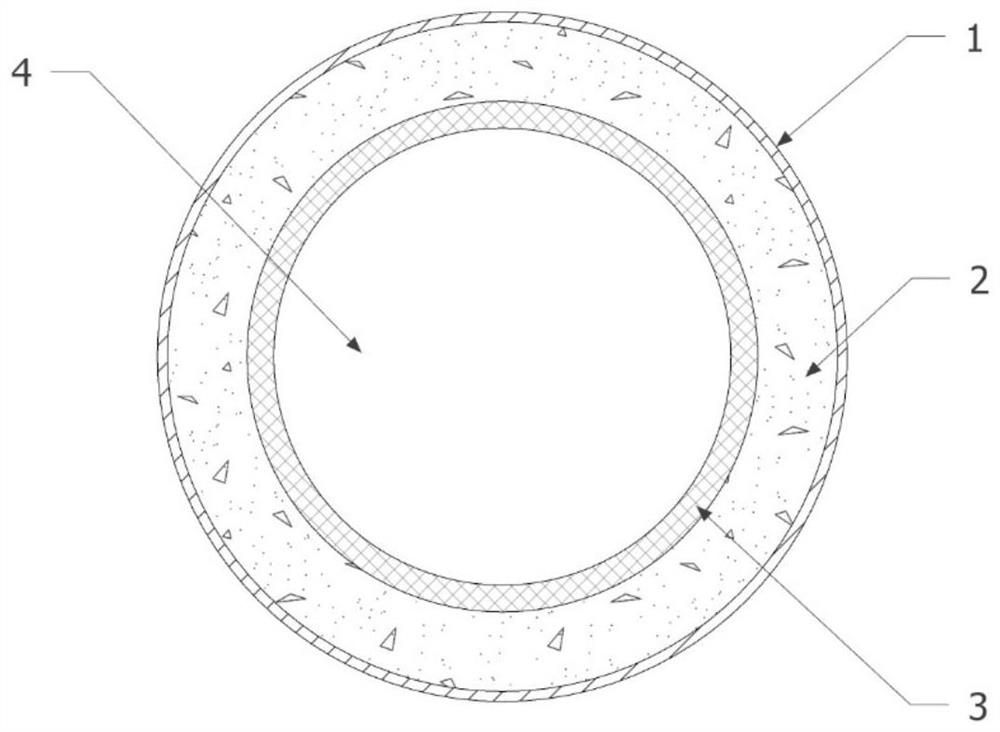

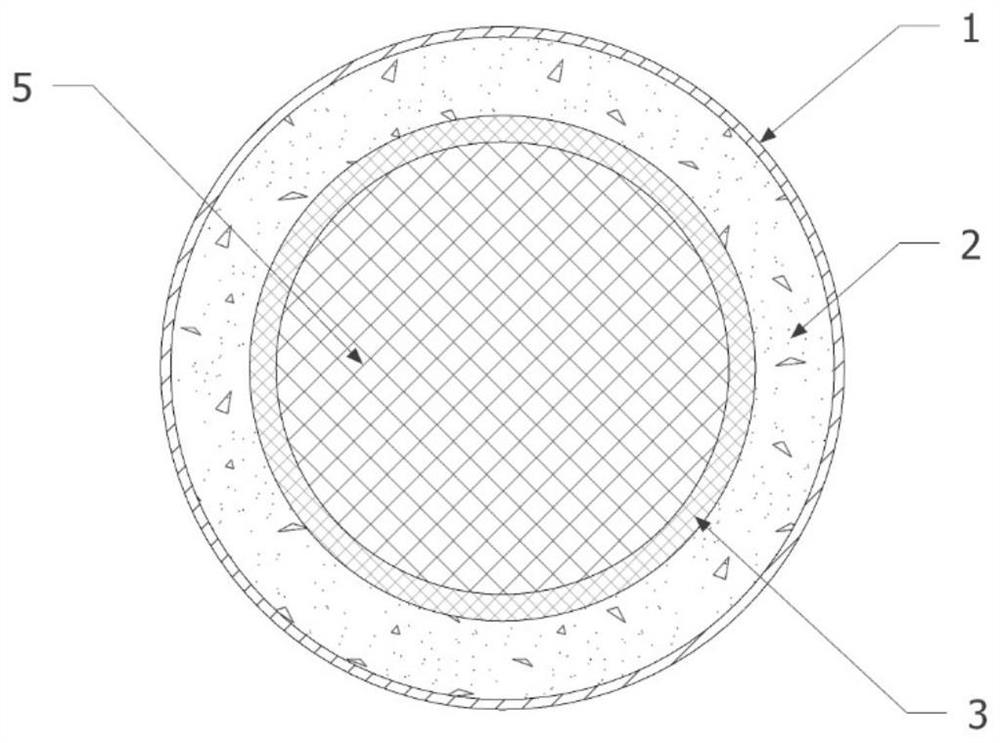

[0041] See attached Figure 2a , 2b , 2c, 2d. in, Figure 2a is A-A sectional view, Figure 2b is the B-B sectional view, Figure 2c is the C-C sectional view, Figure 2d It is a D-D sectional view.

[0042] In this embodiment, the composite pipe-concrete-steel pipe double-walled hollow pier column top support connection node includes a hollow section, a solid section, a gear-shaped cover plate and a bridge support supported on the gear-shaped cover plate from bottom to top. seat; the hollow section is composed of composite pipe, concrete interlayer, and hollow steel pipe from outside to inside, and the hollow steel pipe inside the hollow section is a cavity; the solid section is composed of composite pipe, concrete interlayer, steel pipe and The steel pipe is filled with concrete; the hollow section and the solid section are separated by an inner partition steel plate; the gear-shaped cover plate has a hole in the center for pouring the concrete in the steel pipe of the...

Embodiment 2

[0052] See attached Figure 3a , 3b , 3c, 3d. in, Figure 3a is A-A sectional view, Figure 3b is the B-B sectional view, Figure 3c is the C-C sectional view, Figure 3d It is a D-D sectional view.

[0053] In this embodiment, for the hollow section and solid section of the node, the cross-sectional profile of the composite pipe is circular, with an inner diameter of 800mm and a thickness of 12mm; the steel pipe is a single single-cavity steel pipe, and the cross-sectional profile is square. The outer length is 420mm and the thickness is 20mm;

[0054] In this embodiment, the shape and size of the cross-sectional outer contour of the inner partition steel plate are consistent with the shape and size of the inner contour of the steel pipe cross-section in the hollow section, which is a square (see Image 6 The square inner partition steel plate in the middle) has a side length of 380mm and a thickness of 24mm.

[0055] In this embodiment, the height of concrete filled ...

Embodiment 3

[0061] See attached Figure 4a , 4b , 4c, 4d. in, Figure 4a is A-A sectional view, Figure 4b is the B-B sectional view, Figure 4c is the C-C sectional view, Figure 4d It is a D-D sectional view.

[0062] In this embodiment, for the hollow section and solid section of the node, the cross-sectional profile shape of the composite pipe is square, the inner side length is 700 mm, and the thickness is 12 mm; the steel pipe is a single single-cavity steel pipe, and the cross-sectional profile shape is square. The outer length is 420mm and the thickness is 20mm;

[0063] In this embodiment, the shape and size of the cross-sectional outer contour of the inner partition steel plate are consistent with the shape and size of the inner contour of the steel pipe cross-section in the hollow section, which is a square (see Image 6 The square inner partition steel plate in the middle) has a side length of 380mm and a thickness of 24mm.

[0064] In this embodiment, the gear-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com