Detachable rolling sinking type open caisson structure and construction process

A construction technique and caisson technology, which is applied in infrastructure engineering, caissons, buildings, etc., can solve problems such as unbalanced ballast, increased construction risk, and occupation of construction space on site, so as to reduce side resistance, reduce construction risk, The effect of reducing the construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

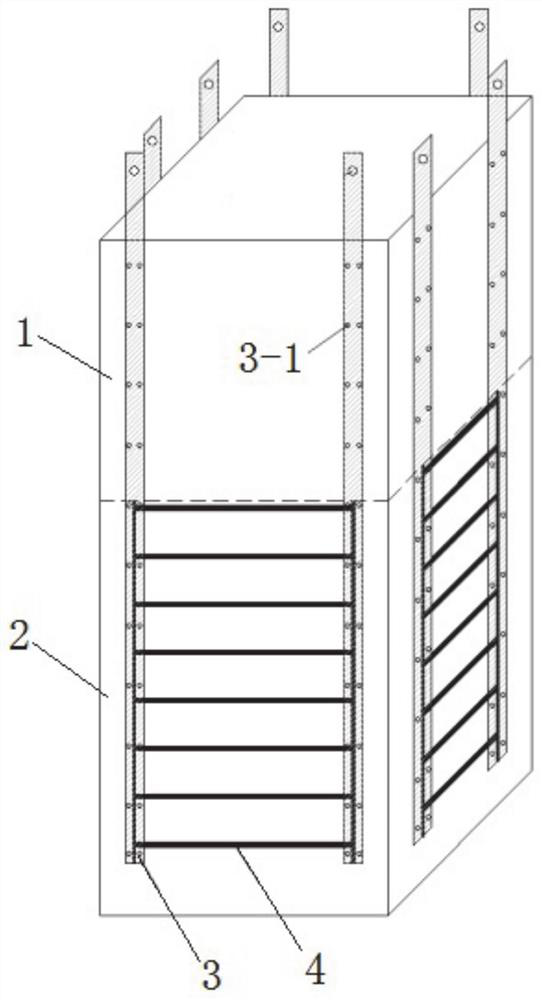

[0031] This embodiment provides a detachable rolling sinking caisson structure, such as figure 1 As shown, it includes the caisson and rolling device. The caisson is poured from the upper caisson section 1 and the lower caisson section 2. The rolling device is set outside the caisson and is detachably connected with the lower caisson section 2. , The side resistance is greatly reduced when the caisson sinks through the rolling device.

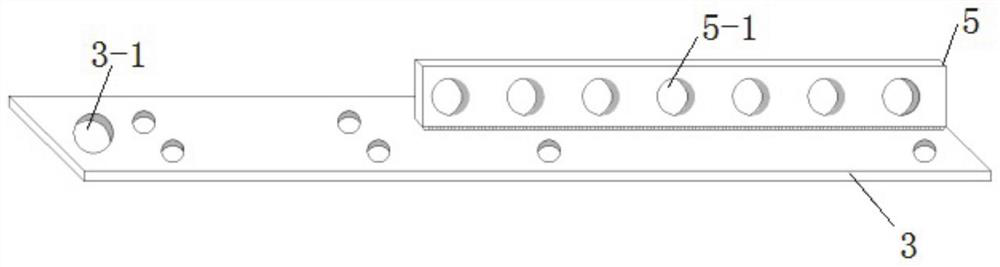

[0032] Further, multiple groups of rolling devices are evenly spaced along the circumference of the caisson, and each group of rolling devices includes at least two vertical plates 3 that are attached to the outer wall of the caisson. When the cross section of the caisson is rectangular, each side of the caisson is The rolling device is installed, and the vertical plate 3 is a rectangular plate; when the cross section of the caisson is circular, the cross section of the vertical plate 3 is arc-shaped.

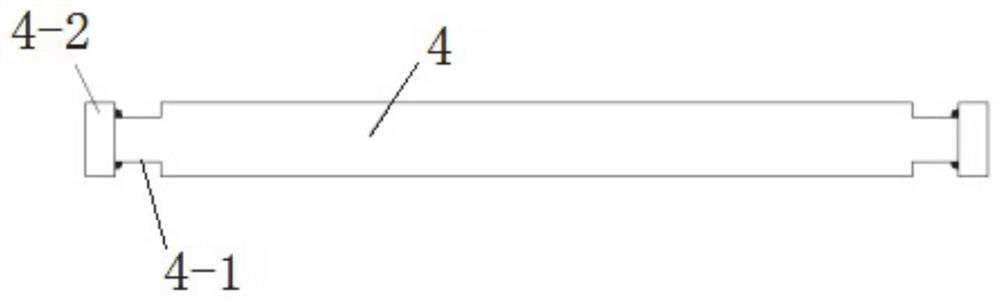

[0033] Preferably, the rolling device in...

Embodiment 2

[0046] This embodiment provides a construction process for a detachable rolling sinking caisson structure. For the caisson structure described in Embodiment 1, the following steps are included:

[0047] Step 1: According to the actual situation of the project and stratum parameters, calculate the section height of caisson divided into upper caisson section 1 and lower caisson section 2.

[0048] Step 2: According to the length and width of the caisson and the calculated section height, prepare the parts of the rolling device, and after drilling holes in the vertical plate 3 and the connecting plate 5, weld and fix them; fix the bearing in the connecting plate 5.

[0049] Step 3: Make the lower caisson section 2 on site, reserve installation holes when binding the steel bars of the lower caisson section 2, take protective measures to prevent the installation holes from being blocked, pour concrete in the lower caisson section and wait for the concrete strength to reach the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com