Flue gas waste heat recovery system of biomass boiler

A biomass boiler, flue gas waste heat technology, applied in the directions of preheating, steam generation, liquid degassing, etc., can solve the problems affecting the safe operation of equipment, can not meet the boiler energy saving, air preheater cold end corrosion, etc., and achieve good heat conduction. performance, reducing equipment investment and operating costs, and the effect of high tensile strength of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

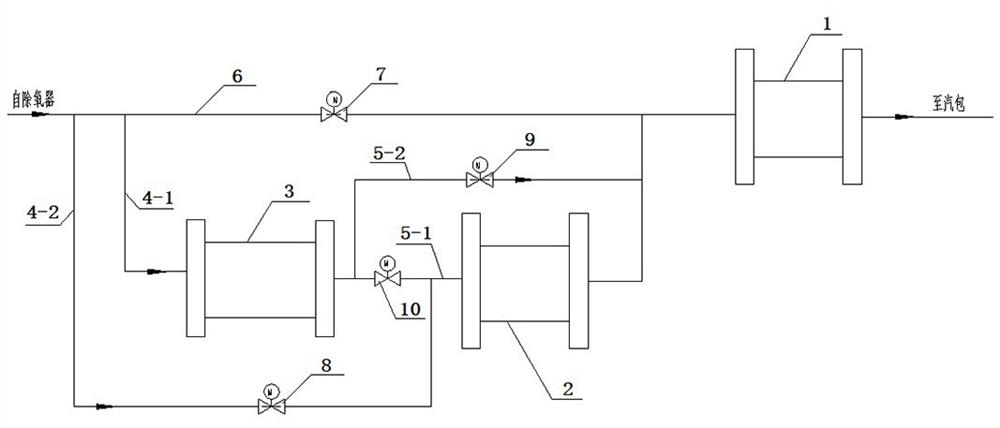

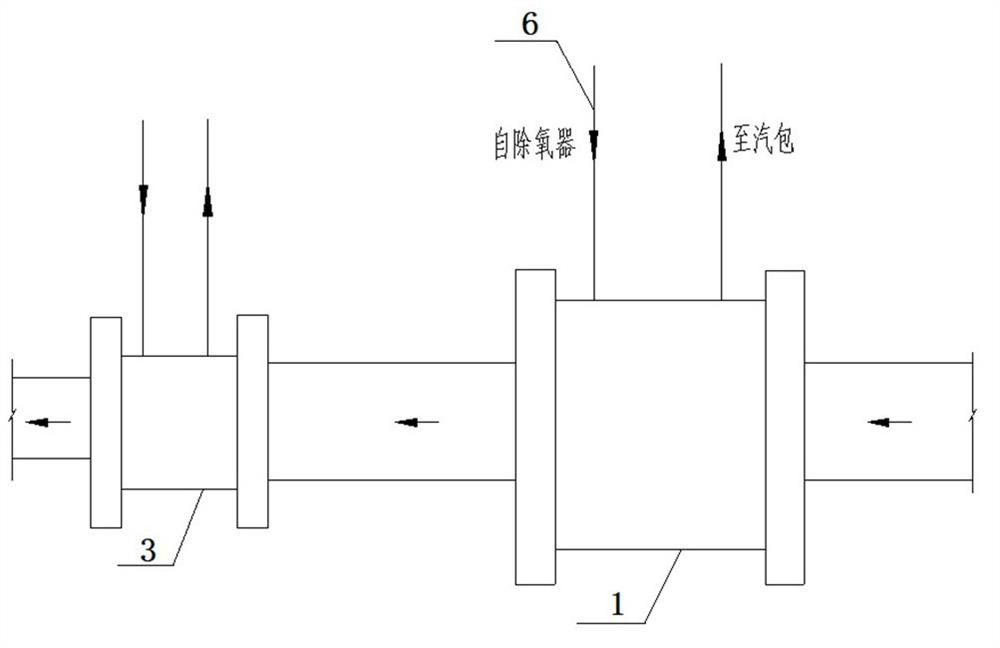

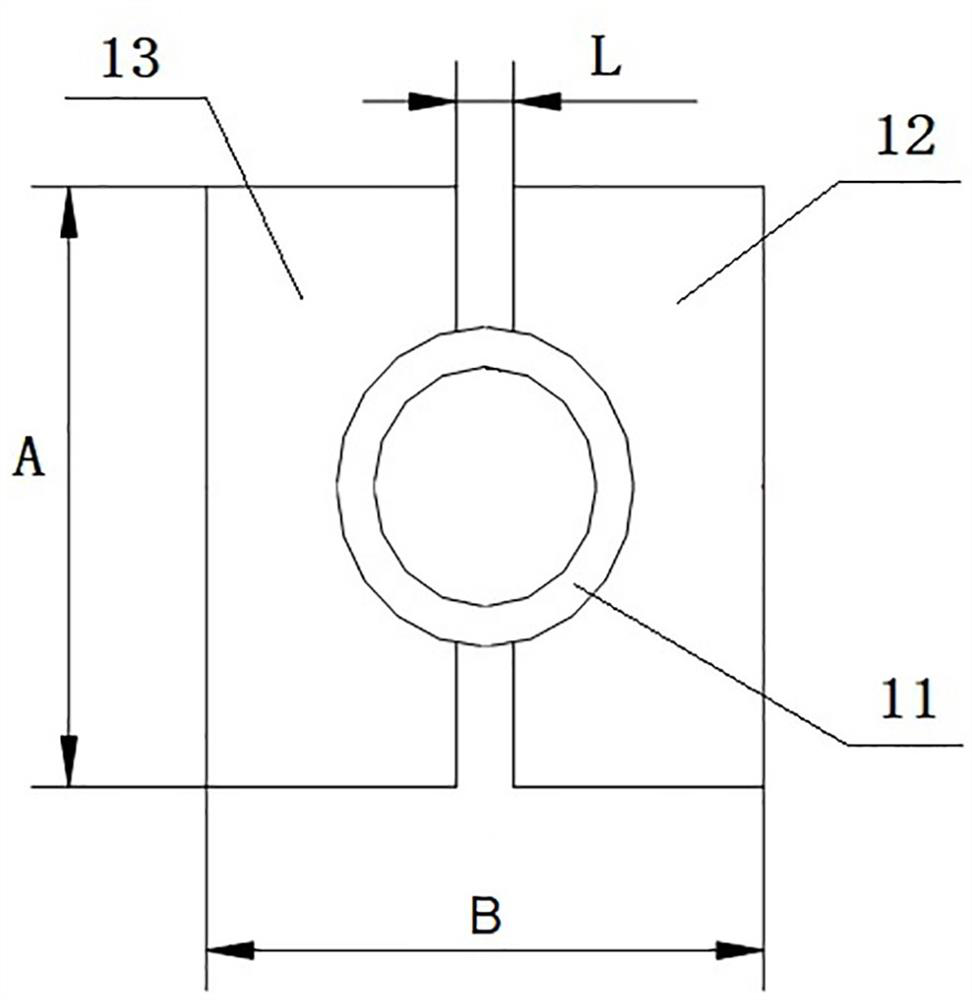

[0034] Such as figure 1 As shown, a biomass boiler flue gas waste heat recovery system includes an economizer 1 connected to the flue gas pipeline, a smoke cooler 2 connected to the economizer, and an air preheater 3 connected to the air pipeline and high-pressure feed water piping from the deaerator;

[0035] The system adds a smoke cooler 2 between the economizer 1 and the air preheater 3, and the preheating of the air does not use flue gas, but is realized by heating the high-pressure feed water from the deaerator to heat the feed water of the air preheater 3 Lead out directly from the high-pressure water supply pipe, preheat the air entering the air preheater 3, then enter the smoke cooler 2 to absorb the heat of the flue gas, and finally return to the high-pressure water supply pipe to enter the economizer 1, and finally enter the steam drum.

[0036] specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com