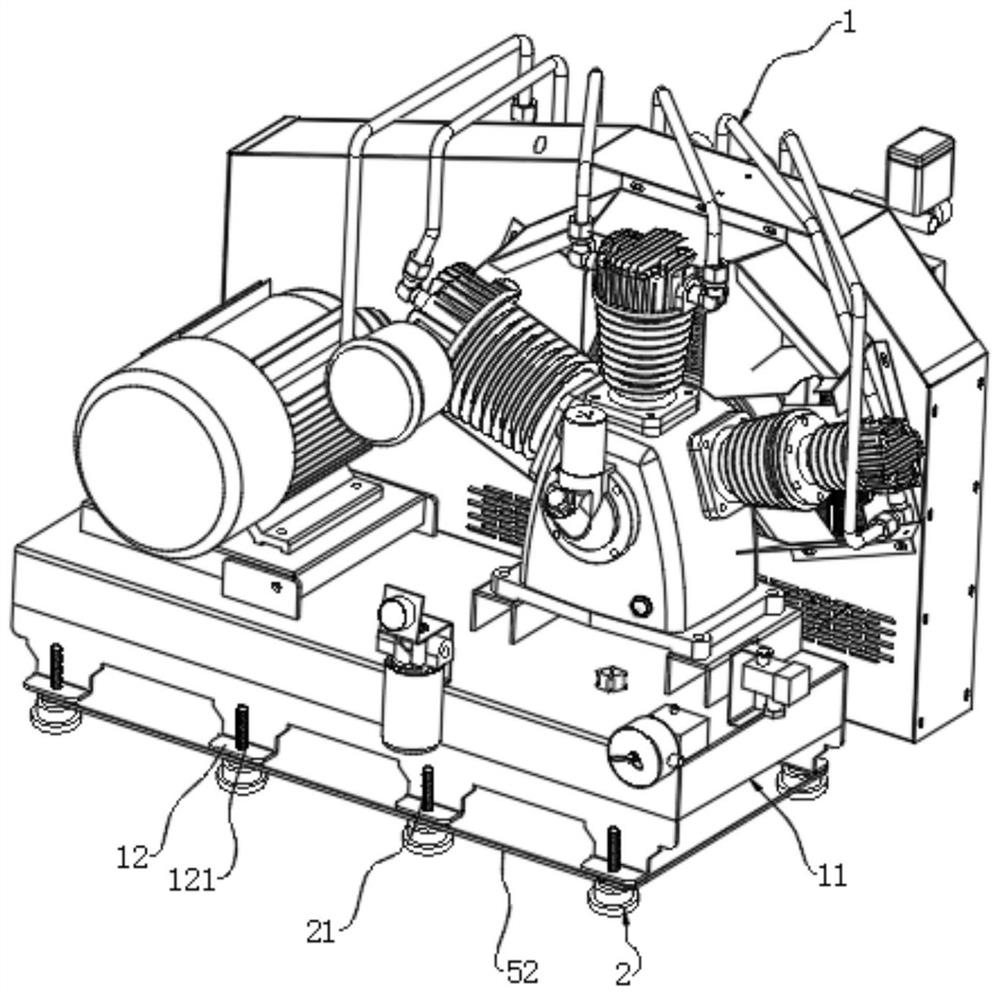

Piston supercharger with buffer structure

A buffer structure, supercharger technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., can solve the problems affecting the life of the supercharger, large vibration of the supercharger, etc. Avoid displacement loosening, avoid the effect of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

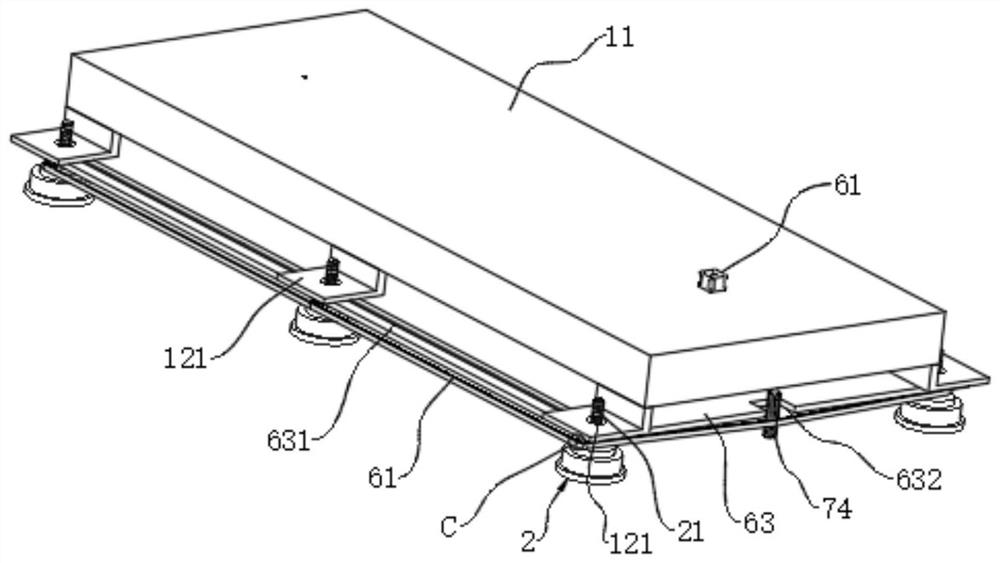

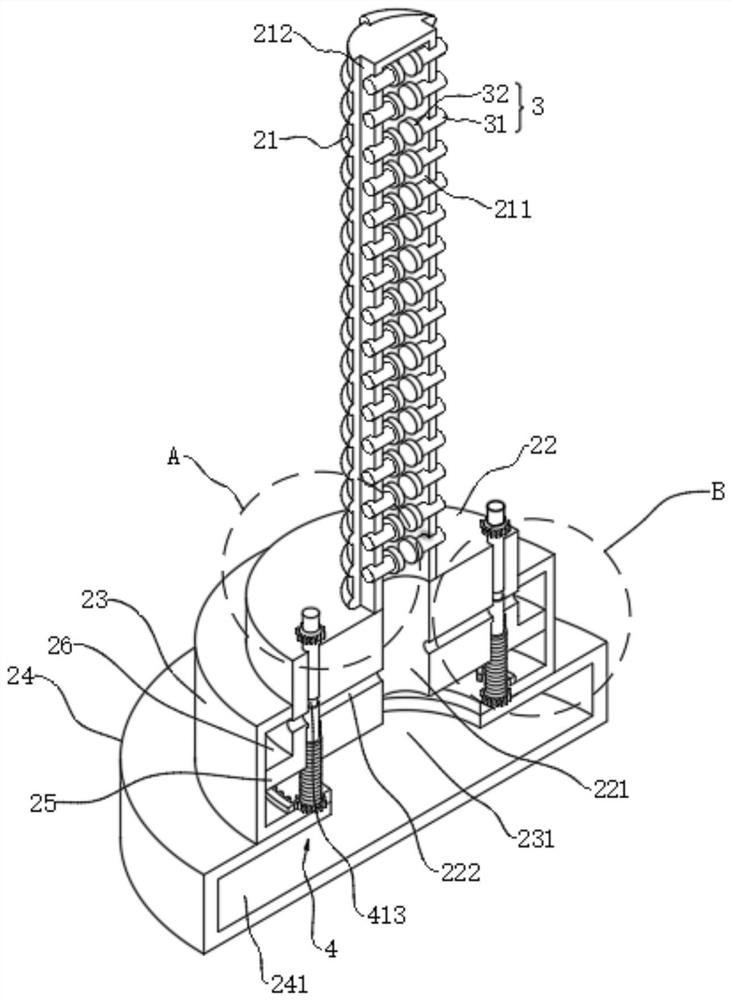

[0030]The embodiment of the present application provides a piston supercharger with a buffer structure. By setting the shock absorber 2, vibration is generated during the operation of the supercharger, and the shock absorber 24 will be deformed and contracted by the vibration and extrusion force. The hydraulic oil inside the shock chamber 241 flows through the first oil chamber 231 and the second oil chamber 221 to form a buffer against the vibration and extrusion force on the shock absorbing pad 24, which solves the problem that the supercharger in the prior art is easy to produce Large vibration, which affects the life of the supercharger, realizes the effect of buffering and assisting the supercharger and reducing the vibration of the supercharger.

[0031] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com