Tobacco processing strip forming device and using method thereof

A molding device and tobacco technology, applied in the direction of tobacco, application, manufacturing of cigarettes, etc., can solve the problems of loss of small factories, high price, occupying space, etc., and achieve the effects of increasing structural stability, preventing waste, and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

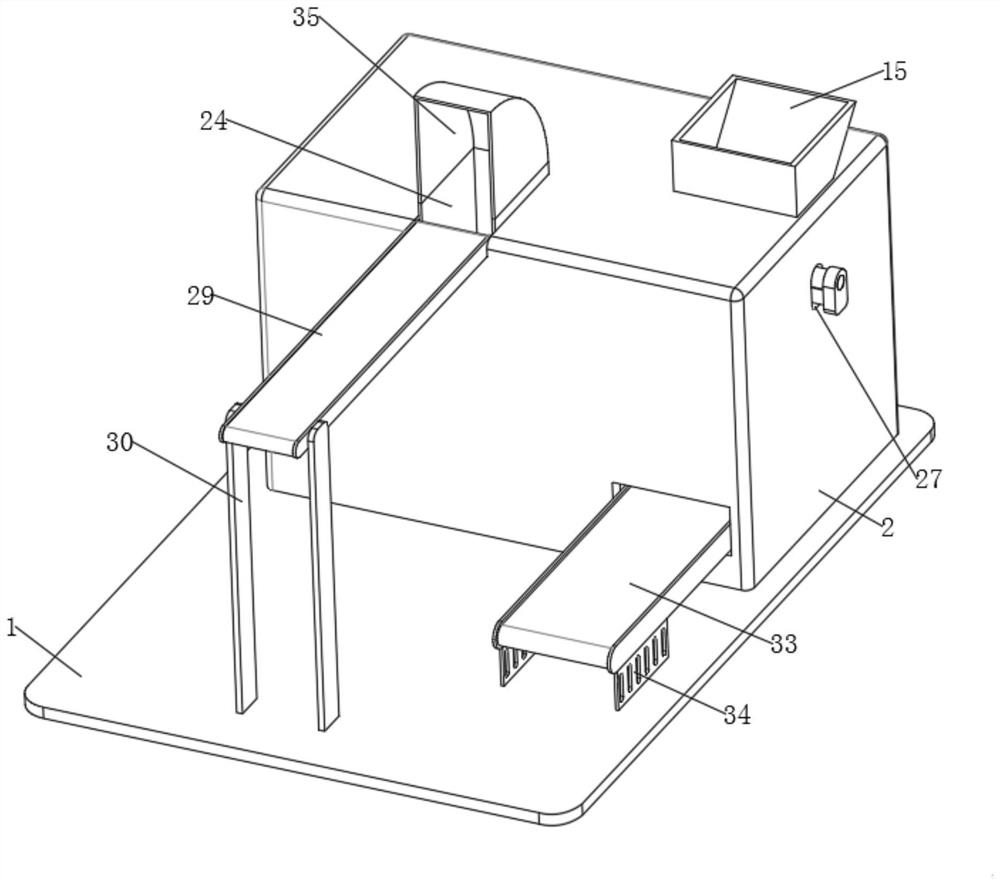

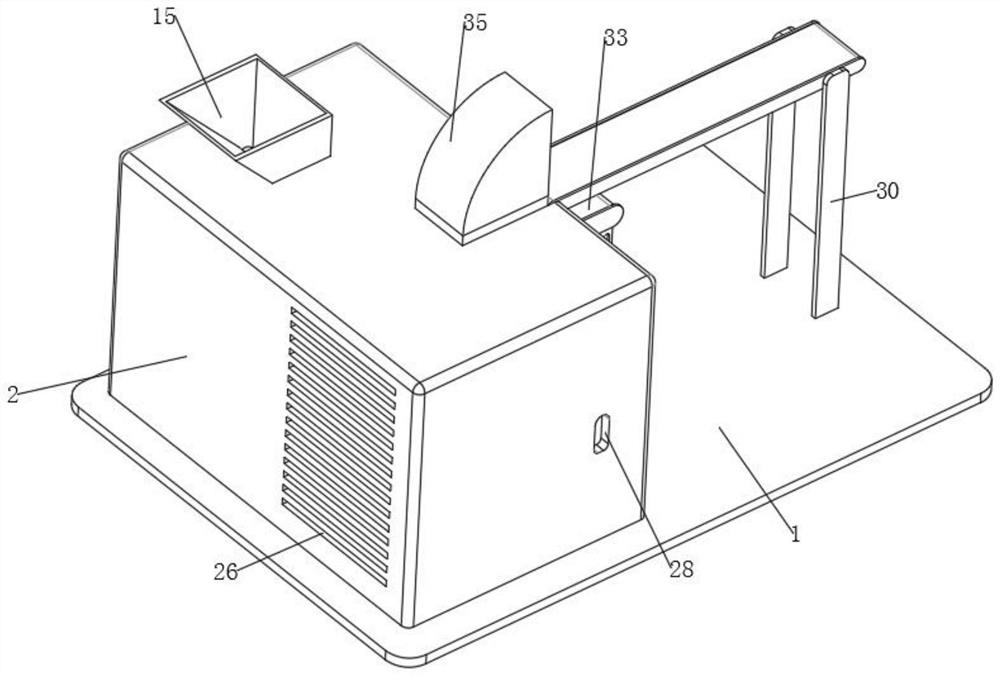

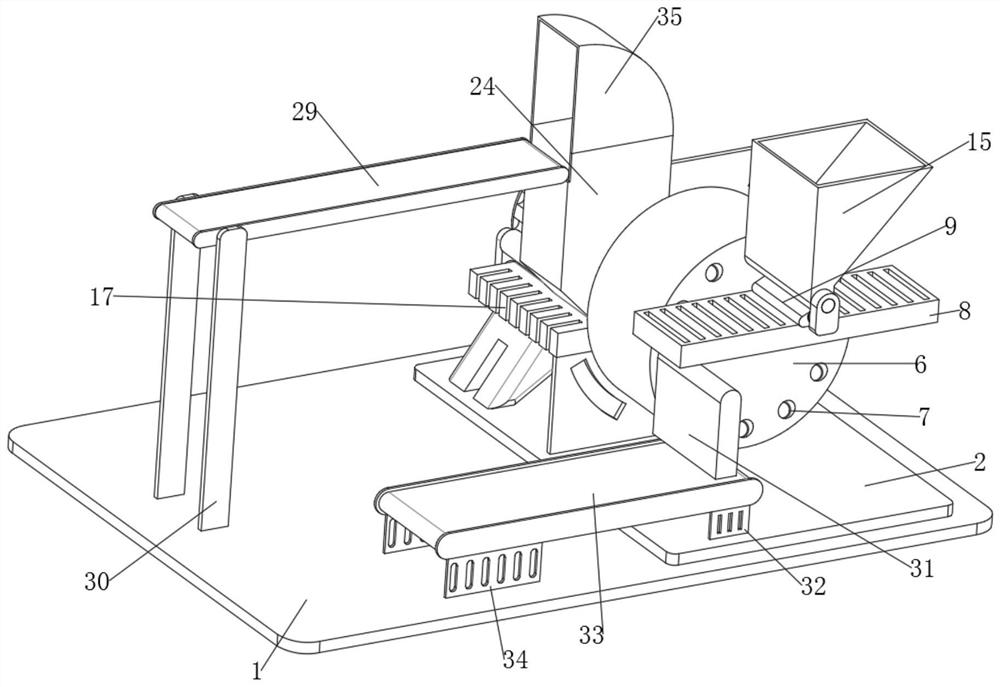

Embodiment 1

[0036] see Figure 1-9 , the present invention provides a technical solution: a tobacco processing rod forming device, including a base 1, a fixed shell 2 is installed on the top of the base 1 close to the rear side edge, and a support is welded on the inner bottom of the fixed shell 2 close to one side edge Frame 3, the top of the support frame 3 is provided with a drive motor 4, the output end of the drive motor 4 is welded with a rotating rod 5, one end of the rotating rod 5 is welded with a turntable 6, and one side of the turntable 6 is equidistantly provided with a plurality of placement holes 7 , the inner walls of a plurality of placement holes 7 are fixedly connected with placement pipes 36, the right side inner wall of the fixed housing 2 is welded with a first support plate 8, the top of the first support plate 8 is welded with a support plate 9, and the top of the support plate 9 is opened There is a first placement slot 10, the inner wall of the first placement slot...

Embodiment 2

[0039] according to Figure 3-8 As shown, the outer surface of the other side of the fixed shell 2 is provided with a second sliding hole 28 that is compatible with the second connecting block 20, and the inner wall of the second sliding hole 28 is slidably connected with the outer surface of the second connecting block 20. A baffle plate 25 is welded between the inner walls of the shell 2, a plurality of ventilation holes 26 are provided on the rear surface of the fixed shell 2, and a first transmission device 29 is arranged on the top of the fixed shell 2 near the edge of the feed pipe 24. The bottom of device 29 is fixedly installed with two first transmission brackets 30, and the bottom of two first transmission brackets 30 is fixedly connected with the top of base 1, and the inner bottom surface of fixed housing 2 is welded with two second ones near the side edge. Transmission bracket 32, a second transmission device 33 is arranged between the tops of the two second trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com