Power supply structure of electric grinding machine tool

An electric grinding and machine tool technology, applied in electric vehicles, manufacturing tools, battery circuit devices, etc., can solve problems such as difficult operation, and achieve the effect of reducing weight and avoiding work injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

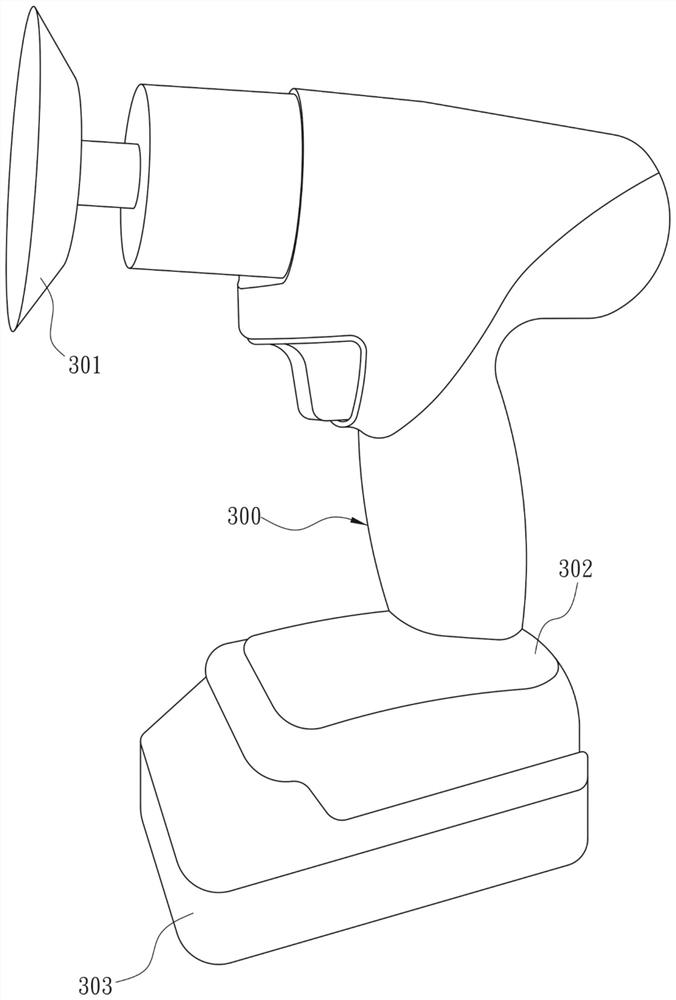

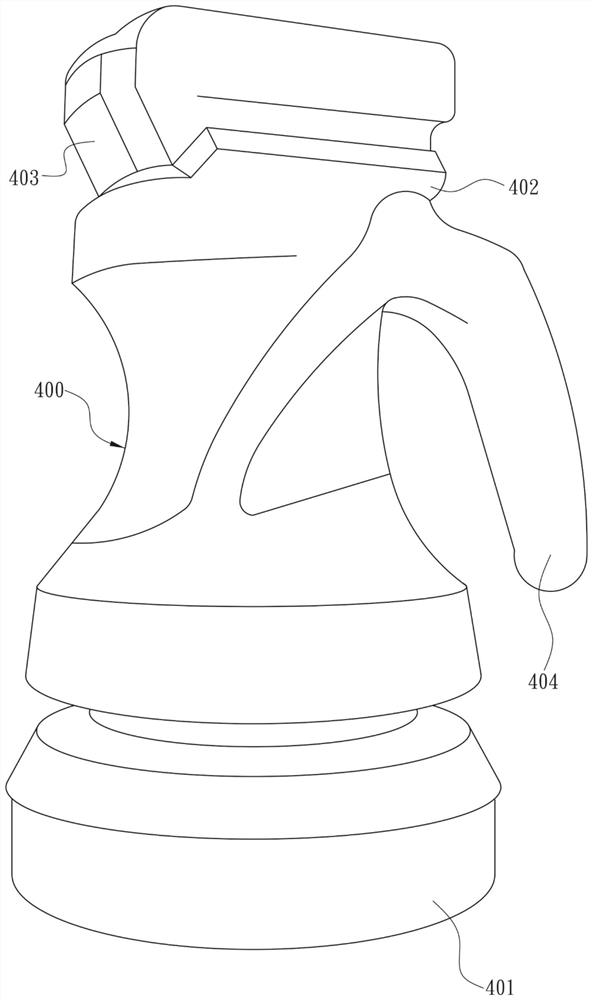

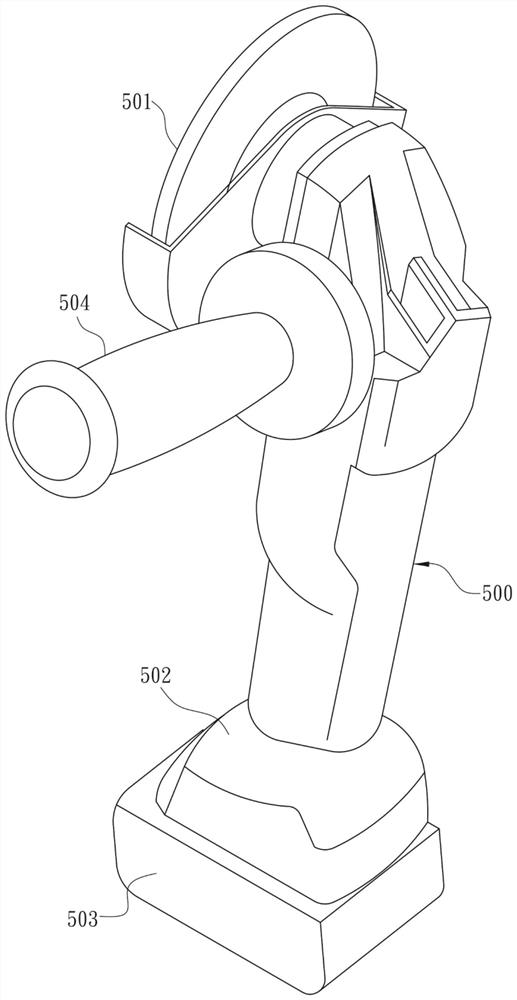

[0079] see Figure 4 to Figure 6 , the present invention provides a power supply structure of an electric grinding tool 100. Firstly, the electric grinding tool 100 of the present invention can be a battery-driven tool, and the electric grinding tool 100 is a tool that needs to be operated continuously for a long time. machine. Moreover, the electric grinding tool 100 of the present invention changes the power supply structure of the electric grinding tool 100 so that when the electric grinding tool 100 is replaced with a replaceable battery 20 as the power source, the replaceable battery 20 is no longer It is directly attached to the main body of the electric grinding tool 100 so that the counterweight of the electric grinding tool 100 will not be generated at one end of the main body of the electric grinding tool 100 .

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com