Integrated connecting disc storage rack

A technology for storage racks and connection trays, applied to multi-axis trolleys, trolley accessories, trolleys, etc., can solve the problems of messy storage of connection trays, low transfer efficiency and low efficiency of connection trays, and achieve improved storage capacity, easy movement, and lifting The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

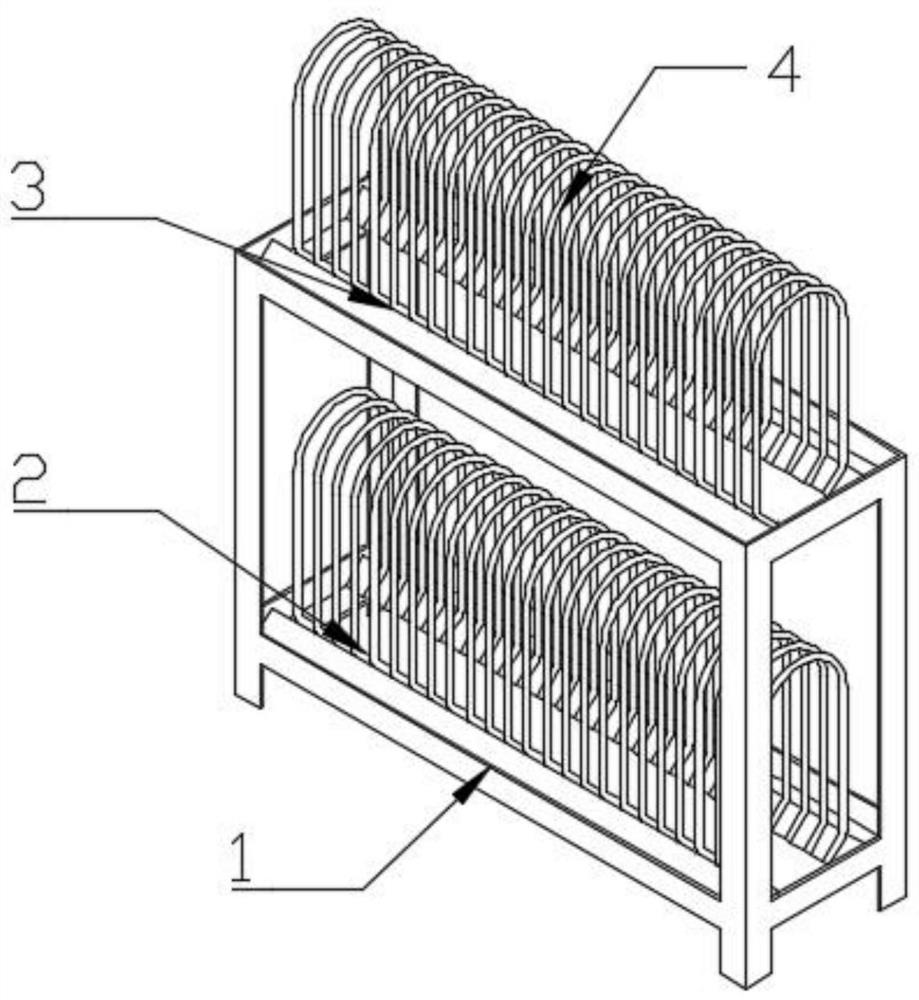

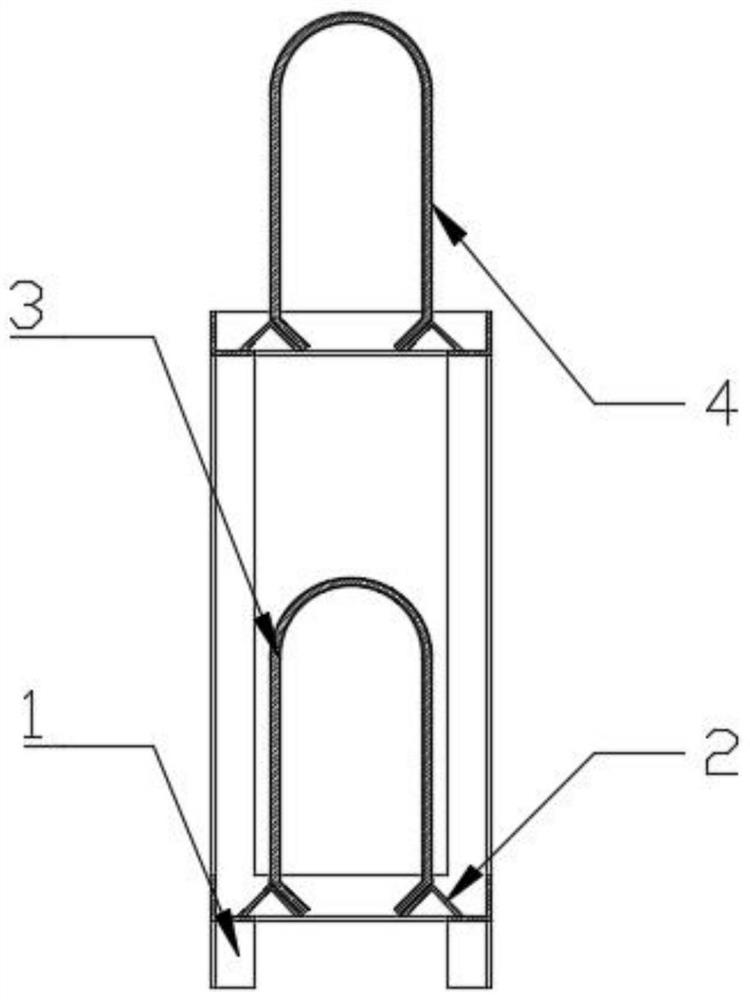

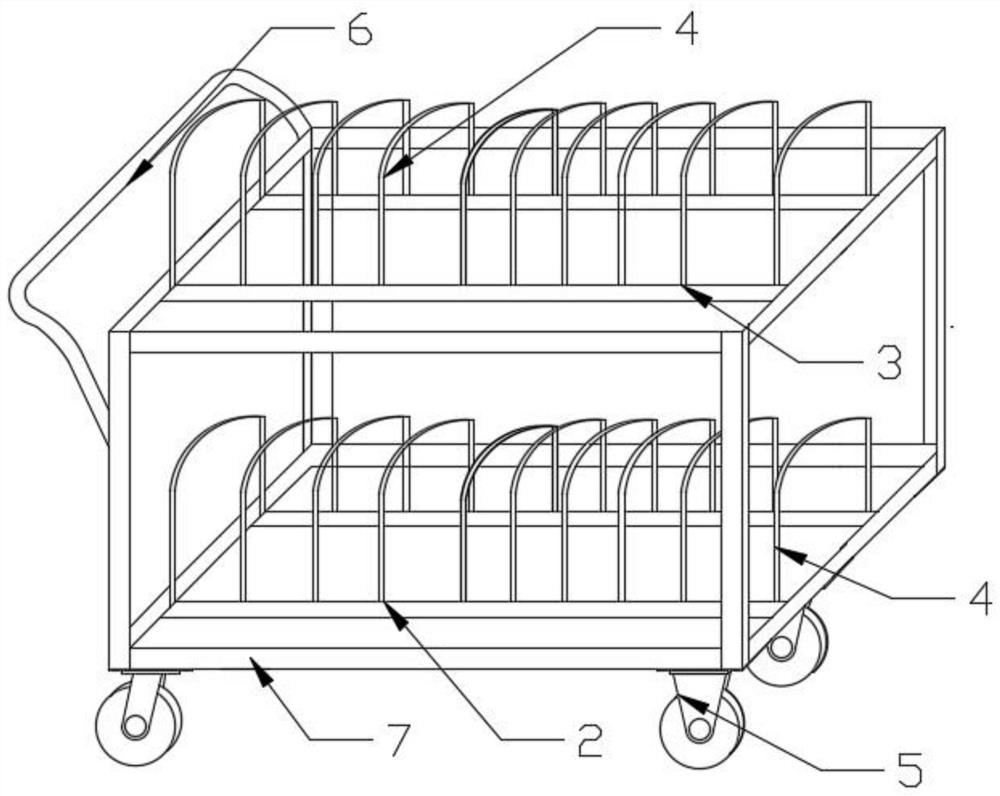

[0022] refer to figure 1 and figure 2 As shown, an integrated connection plate storage rack, including: a structural frame 1, the structural frame 1 is welded by aluminum alloy square structure pipes, and two groups of Tripod 2, described tripod 2 is the angle iron structural block that opening is downward, and two groups of tripods 2 insides are welded and installed with several groups of lower storage racks 3, and described tripods 2 upper inners are welded with several groups of upper storage racks 4, so The lower storage rack 3 and the upper storage rack 4 are U-shaped structural blocks with the same structure. The lower storage rack 3 and the upper storage rack 4 are aluminum alloy materials with good corrosion resistance. The lower storage rack 3 and the upper storage rack The outer surface of frame 4 is provided with a rubber protection layer, and the surface of the rubber protection layer is provided with anti-skid stripes distributed vertically and horizontally, whi...

Embodiment 2

[0024] refer to figure 1 and figure 2 As shown, an integrated connection plate storage rack, including: a structural frame 1, the structural frame 1 is welded by aluminum alloy square structure pipes, and two groups of Tripod 2, described tripod 2 is the angle iron structural block that opening is downward, and two groups of tripods 2 insides are welded and installed with several groups of lower storage racks 3, and described tripods 2 upper inners are welded with several groups of upper storage racks 4, so The lower storage rack 3 and the upper storage rack 4 are U-shaped structural blocks with the same structure. The lower storage rack 3 and the upper storage rack 4 are aluminum alloy materials with good corrosion resistance. The lower storage rack 3 and the upper storage rack The outer surface of frame 4 is provided with a rubber protection layer, and the surface of the rubber protection layer is provided with anti-skid stripes distributed vertically and horizontally, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com