Assembly line capable of automatically recycling carriers

An assembly line and automatic recovery technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of unguaranteed conveying work, wear of conveyor belt brackets, and general stability of adaptation, etc., to improve the flexibility of use , Quick disassembly and replacement, easy to replace the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

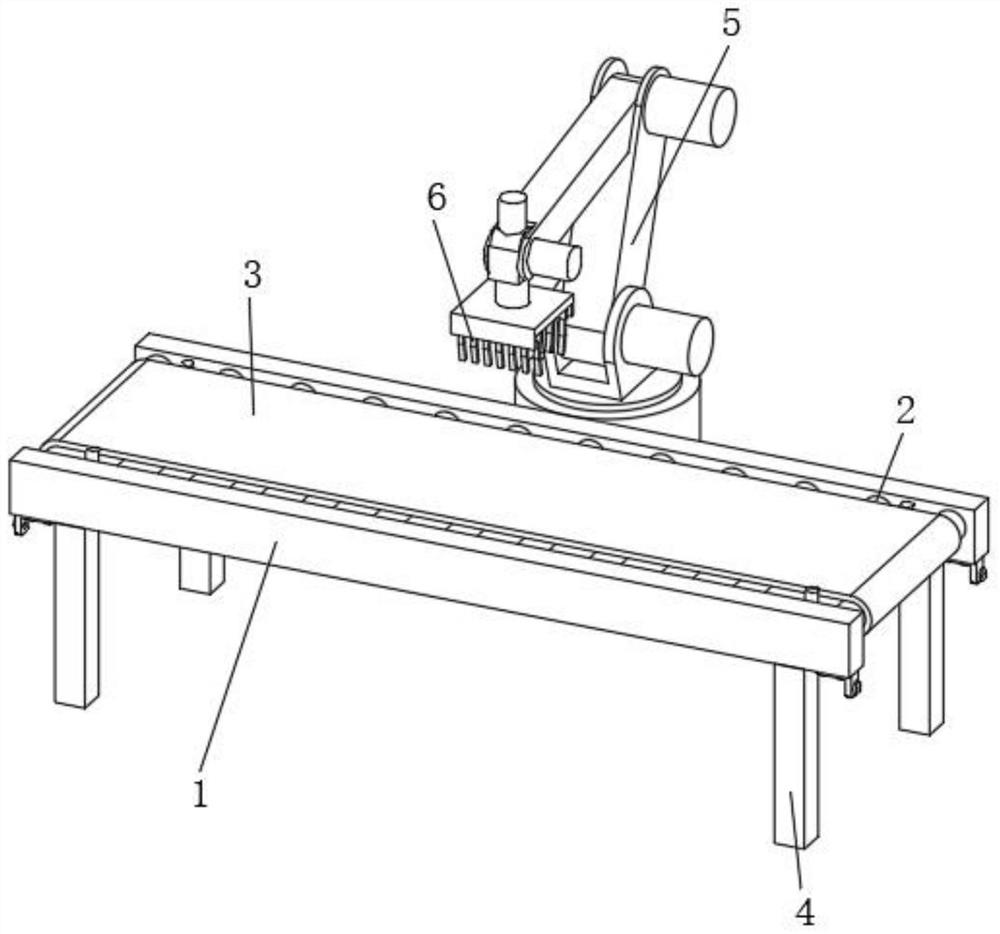

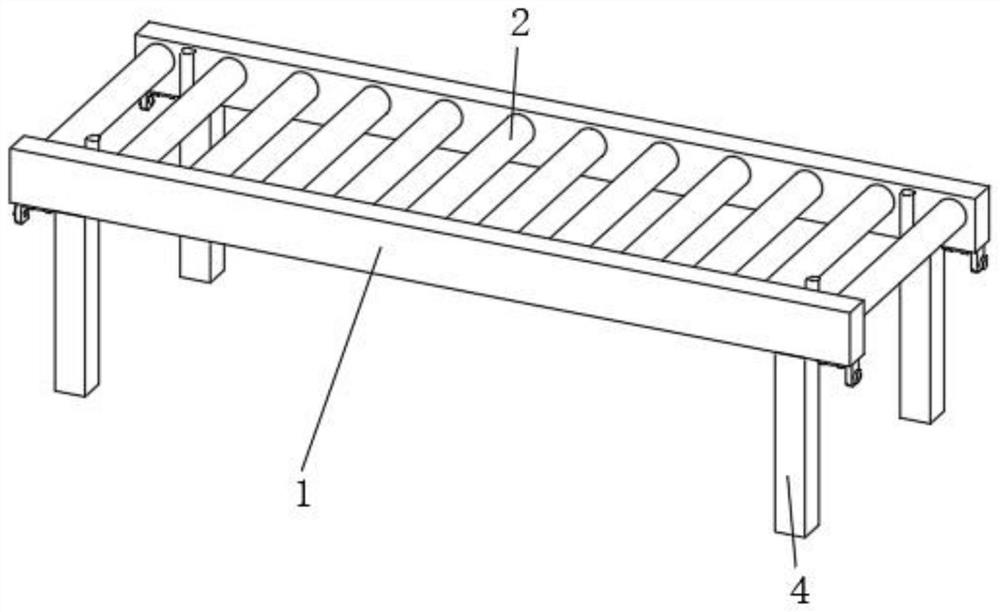

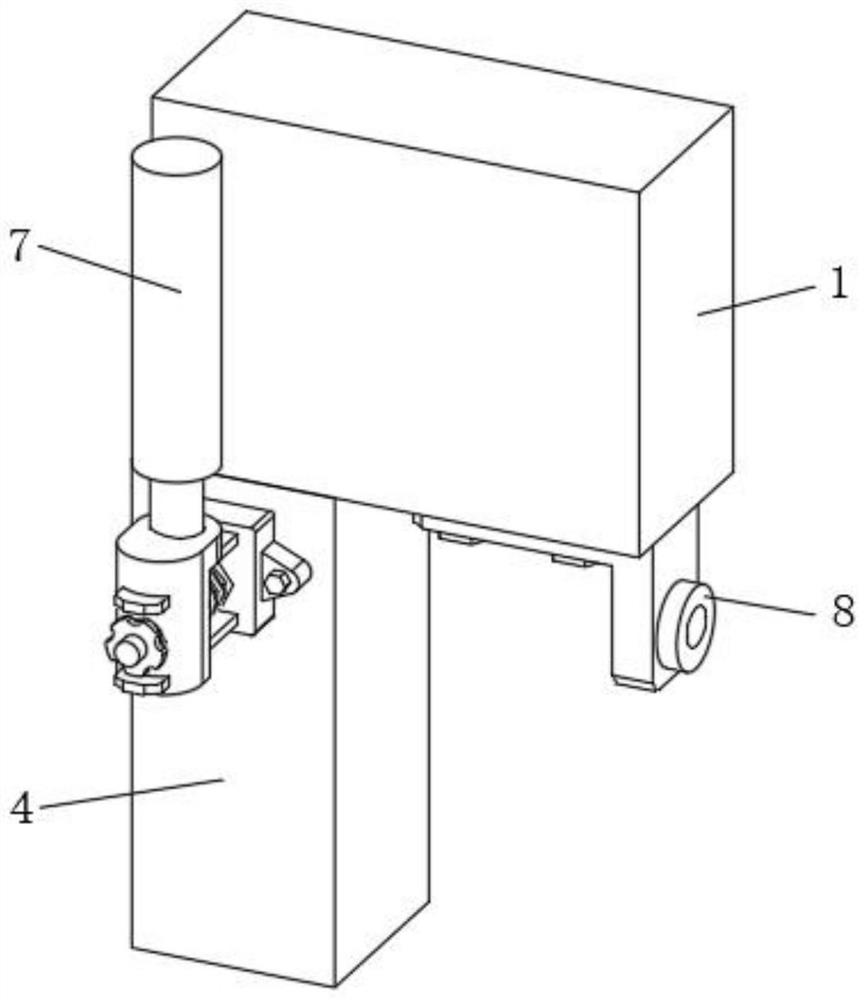

[0022] Such as Figure 1-5 As shown, an assembly line that can automatically recover the carrier includes a conveyor frame 1 and a mechanical arm 5. A conveyor roller 2 is arranged on the inner side of the conveyor frame 1, and a conveyor belt 3 is sleeved on the conveyor roller 2. The conveyor frame 1 Outriggers 4 are fixedly installed on the lower surface, and the mechanical arm 5 is located at a position close to the conveying frame 1, and the end of the mechanical arm 5 is provided with a clamping mechanism 6, and a connecting structure 8 is fixedly installed on the conveying frame 1, and the connecting structure 8 includes Fixing frame 801, mounting bolts 802, round holes 803, rubber blocks 804, insert blocks 805 and through holes 806, rubber blocks 804 are installed on the fixing frame 801, and the fixing frame 801 is fixedly installed on the conveyor frame 1 and the supporting legs 4 An anti-bias mechanism 7 is provided, and the anti-bias mechanism 7 includes a fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com