Connecting construction method for vertical prestressed tendon and anchoring steel bar of prefabricated solid pile

A vertical prestressing and anchoring steel bar technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as increased construction costs, deformation, and reduced construction quality, so as to avoid the consumption of manpower and material resources and ensure the connection quality , Strong field applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

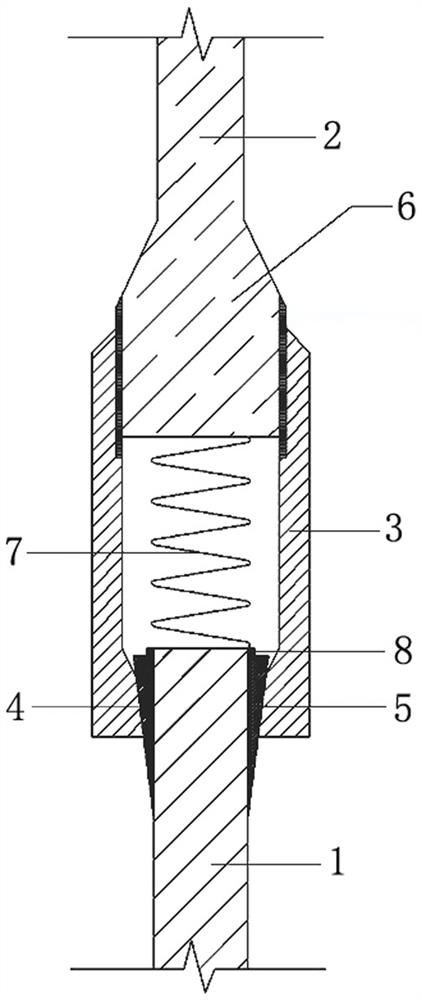

[0021] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0022] A method for connecting prefabricated solid pile vertical prestressed tendons and anchoring steel bars, comprising the following steps:

[0023] 1) Prepare the connecting sleeve 3. The inner wall of the top mouth of the connecting sleeve 3 is provided with a connecting thread, and the bottom mouth of the connecting sleeve 3 is contracted to form a rounded table-shaped bayonet 4.

[0024] 2) Set the pier head 6 at the connecting end of the anchoring steel bar 2, and set the connecting thread on the outer surface of the pier head 6.

[0025] 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com